Kingsgrove Branch:

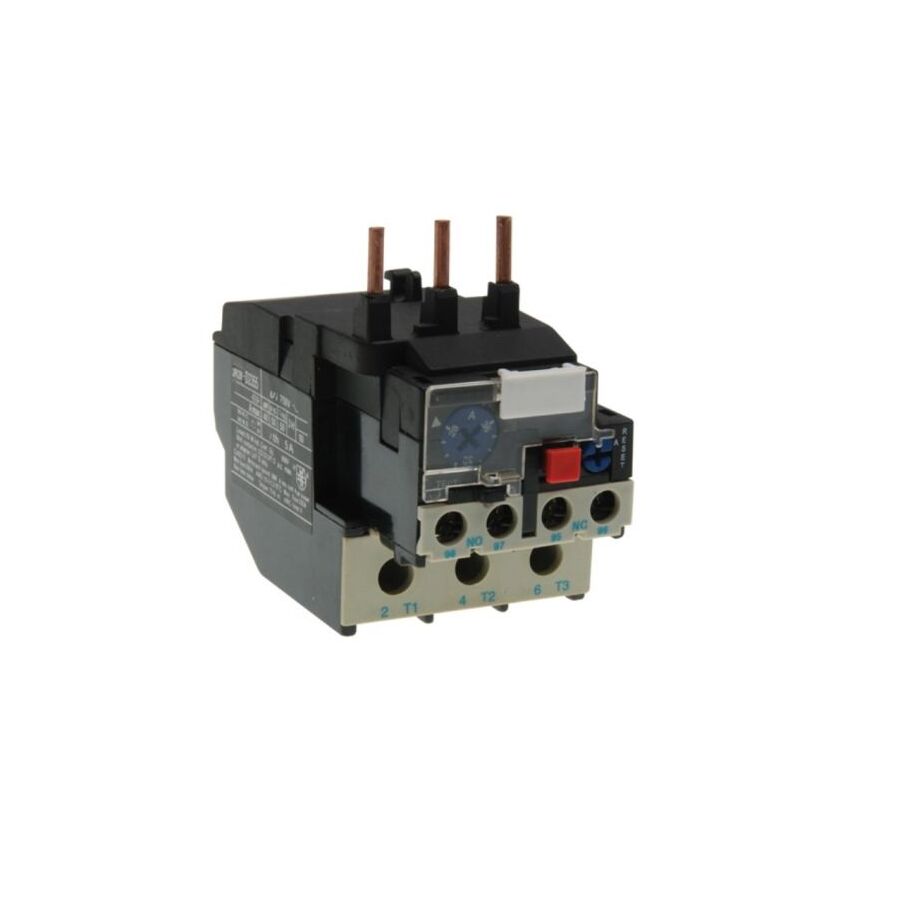

Thermal Overload

G'day! If you run a workshop, a farm, or even just a heavy-duty pool pump, you know that electric motors are the workhorses of the Australian lifestyle. They run our air compressors, conveyor belts, and water pumps day in and day out. However, motors have a weakness. If they are pushed too hard or something jams, they get hot. If they get too hot, the internal windings melt, and your expensive equipment is absolutely cactus.

This is where the thermal overload comes into play. It is a critical piece of safety circuitry designed specifically to protect motors from burning out. While a standard circuit breaker protects the cable from a short circuit, the overload relay protects the machine itself from working itself to death.

How Does a Thermal Overload Relay Work?

It is actually a fairly simple but ingenious bit of engineering. A thermal overload relay contains a small bimetallic strip. The electrical current flowing to the motor passes through a small heating element next to this strip.

If the motor is running normally, the strip stays cool. However, if the motor starts to struggle—perhaps a bearing is seizing up or the pump is blocked—it draws more current. This extra current creates heat. The bimetallic strip heats up and bends. If it bends far enough, it hits a trip mechanism that cuts the power to the contactor, shutting down the motor before permanent damage occurs. It is a fail-safe system that mimics the heating characteristics of the motor.

Why You Cannot Rely on Just a Circuit Breaker

Many people make the mistake of thinking a standard circuit breaker will protect a motor. In most cases, it won't. A circuit breaker is designed to trip instantly if there is a massive surge of current, like a short circuit.

However, a motor burnout usually happens slowly. The motor might be drawing just 10 per cent more power than it should over a few hours. A standard breaker won't notice this slight increase, but that extra heat is slowly destroying the motor insulation. A thermal overload is sensitive enough to detect these small but sustained increases in current and trip the system to save your gear.

Setting It Up Correctly

When you open the control box, you will see a small dial on the face of the relay. This is the amperage setting. For the device to work effectively, this dial must be set to match the Full Load Current (FLC) rating stamped on the motor's compliance plate.

If you set it too high, the motor will burn out before the relay trips. If you set it too low, you will get "nuisance tripping" every time you try to start the machine. It is a fine balance that requires a professional touch.

Sourcing the Right Protection

Because motors come in all shapes and sizes, protection relays do too. When a professional contractor is building a motor starter or replacing a faulty unit, they will typically head to a dedicated electrical wholesaler to find the exact match. They need to ensure the relay is compatible with the contactor and covers the correct amperage range for the specific motor being used. Using a generic part from a hardware store often leads to compatibility issues and unprotected machinery.

Professional Installation is Mandatory

Integrating a protection relay into a motor starter involves working with 240V or 415V mains power. This is not a job for the home handyman.

In Australia, all fixed wiring and work on electrical control panels must be performed by a licensed electrician. They have the testing equipment to measure the actual running current of the motor and fine-tune the thermal overload setting to ensure maximum protection. They will also ensure the reset mode (Manual or Auto) is set correctly for safety, preventing the machine from starting unexpectedly after it cools down.

Heavy-Duty Motor Control from Schnap Electric

If you rely on your machinery to get the job done, you need protection you can trust. A failed relay can result in thousands of dollars in damage to motors and production downtime.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of motor control gear, including high-quality thermal overload relays, contactors, and Direct On Line (DOL) starters. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your pumps, fans, and machinery are protected by robust, reliable components built for Australian conditions. Don't wait for the smoke to come out of your motor; upgrade your protection with Schnap Electric.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products