Kingsgrove Branch:

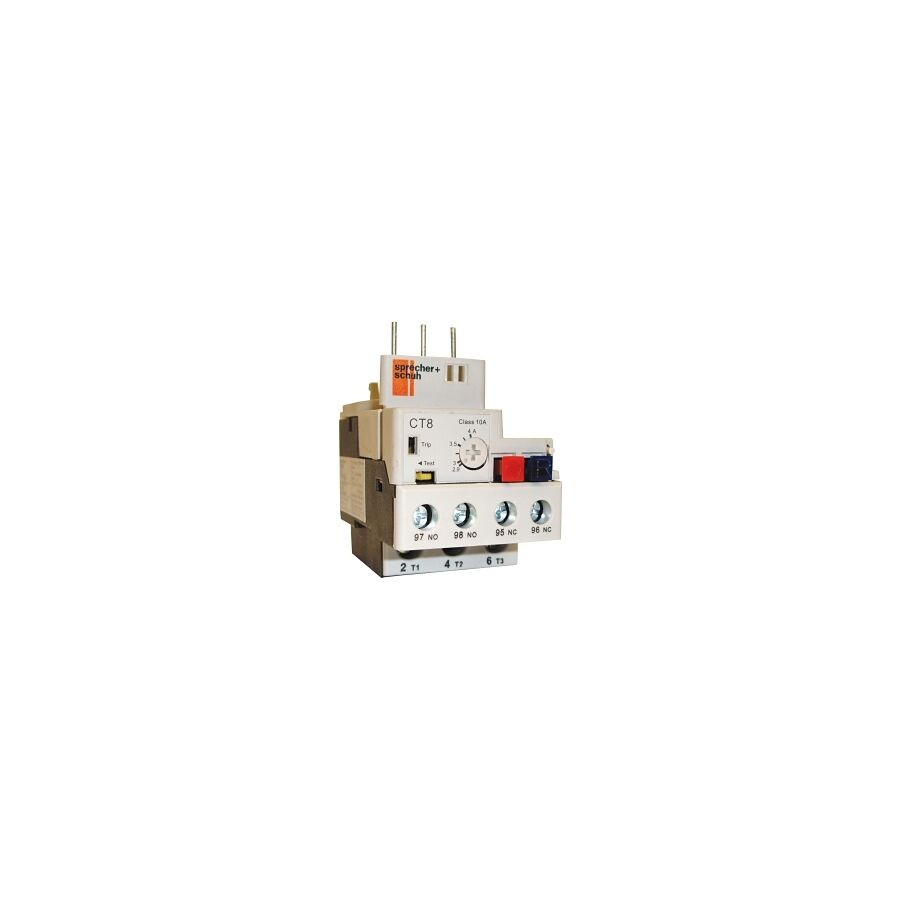

Thermal Overload Relay

G'day! Whether you are running a farm irrigation pump, a workshop compressor, or a commercial exhaust fan, the electric motor is the heart of the operation. These pieces of equipment cost a motza to replace, so the last thing you want is for one to burn out because it was pushed too hard. While fuses and circuit breakers protect your cabling, they are often too slow to save a struggling motor. This is why a thermal overload relay is an absolutely non-negotiable piece of kit for any motor control setup.

This device acts as a dedicated bodyguard for your machinery. It monitors the current flowing into the motor and, if things get too hot or heavy, it steps in to cut the power before permanent damage occurs. Understanding how this device works can save you thousands in repairs and downtime.

How Does a Thermal Overload Relay Work?

The concept is simple but incredibly effective. Inside a thermal overload relay, the electrical current passes through a heating element that sits next to a bimetallic strip.

When the motor is running within its normal limits, the strip stays relatively cool. However, if the motor starts to struggle—perhaps the pump is blocked or the bearings are seizing up—it draws more current than it should. This extra current generates heat inside the relay. The bimetallic strip heats up and bends. If it bends far enough, it hits a trip mechanism that opens the control circuit, shutting down the contactor and stopping the motor instantly. It effectively mimics the heating curve of the motor windings, ensuring the power is cut before the insulation melts.

Why You Cannot Just Use a Circuit Breaker

A common misconception is that a standard circuit breaker provides enough protection. It doesn't. A circuit breaker is designed to trip instantly during a massive fault, like a short circuit, to protect the building's wiring.

A motor burnout, however, is usually a slow process caused by a slight "overload." For example, a motor rated for 10 Amps might be drawing 12 Amps because of a mechanical load issue. A standard breaker won't notice this small increase, but that extra current is slowly cooking the motor. A thermal overload relay is sensitive enough to detect this specific condition and trip the system, saving your equipment from becoming completely cactus.

Selecting the Right Unit

Because every motor is different, you cannot just grab any relay off the shelf. The device must be matched to the Full Load Current (FLC) of the motor it is protecting.

Most relays have an adjustable dial on the front. This allows the installer to fine-tune the trip point to match the exact amperage of the motor. If you set it too high, the motor burns out. If you set it too low, the machine trips every time you turn it on. When sourcing these components, a professional will usually head to a specialized electrical wholesaler to find a relay with the correct adjustment range and compatibility with the motor starter (contactor) being used.

Installation and Safety

Integrating motor protection is a complex job. It involves working with control wiring and often 415V three-phase power. This is strictly regulated work in Australia.

You must engage a licensed electrician to install or replace a thermal overload relay. They have the testing equipment to measure the actual running current of the motor and set the relay precisely. They will also ensure the device is wired to stop the motor safely and prevent it from restarting automatically if that presents a safety hazard to operators.

Reliable Motor Control from Schnap Electric

If you rely on your machinery to make a living, you need components that are built to last. A cheap relay that fails to trip can cost you a brand new motor.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of motor control gear, including high-quality thermal overload relay units designed to integrate seamlessly with their range of contactors. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your industrial and commercial equipment is protected by robust, reliable safety mechanisms. Don't risk your motors; upgrade your protection with Schnap Electric.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products