Kingsgrove Branch:

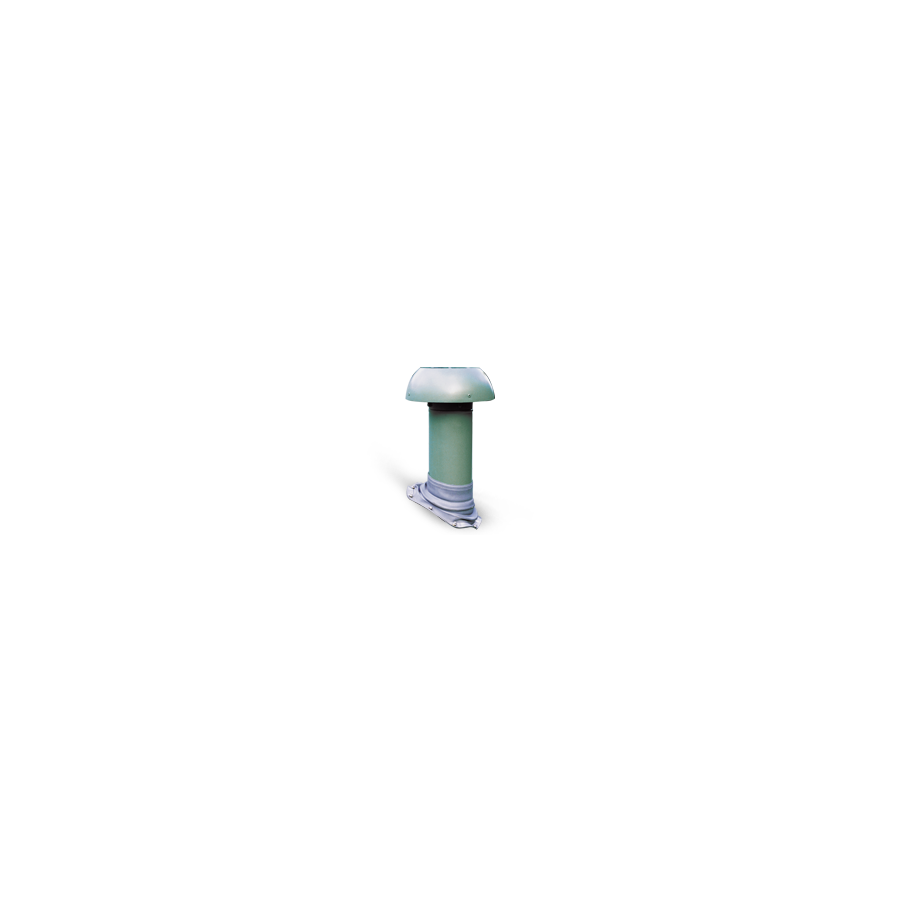

Thru Roof Exhaust Fan

In the modern Australian residential environment, indoor air quality management is no longer optional. As building codes continue to prioritise energy efficiency, homes are becoming increasingly airtight. While this reduces heating and cooling losses, it also traps moisture generated from everyday activities such as showering, cooking, and laundry use. If this moisture is not extracted efficiently, it migrates into roof cavities, condenses on framing timbers, and creates ideal conditions for mould growth and structural decay.

The thru roof exhaust fan is the most aerodynamically efficient residential solution for removing humid air in single-storey homes, particularly those with metal roofing. By discharging air directly through the roof, this system avoids the airflow losses associated with long horizontal duct runs and uses the natural upward movement of warm air to accelerate moisture removal. When correctly specified and installed, it delivers faster extraction, quieter operation, and superior long-term protection of the building fabric.

Vertical Discharge and Static Pressure Efficiency

Every ventilation system is governed by static pressure. Each bend, metre of ducting, and flexible section adds resistance that reduces actual airflow at the grille. In many residential installations, ceiling-mounted exhaust fans are connected to eave vents via long duct runs with multiple bends. While the fan may be rated at a certain airflow, the delivered extraction can be less than half once duct losses are accounted for.

A thru roof exhaust fan eliminates most of this resistance. The fan is either mounted directly above the room or connected via a short, rigid vertical riser. This straight vertical path significantly reduces static pressure losses. It also leverages the stack effect, where warm, moist air naturally rises. As a result, the fan does not need to work as hard to remove steam, improving efficiency and reducing motor strain.

High-quality thru roof systems often use mixed-flow or centrifugal impellers housed within the roof cowl itself. By positioning the motor and impeller outside the ceiling plane, noise is removed from the living space. This design also allows the fan to generate enough suction to actively pull moisture from the room rather than relying on passive diffusion.

Weatherproofing and Roof Penetration Integrity

Penetrating the roof introduces an obvious risk. In Australia’s climate, roofs are exposed to extreme UV, high temperatures, heavy rain, and wind-driven storms. Any weakness in sealing will eventually lead to leaks.

Professional thru roof installations rely on a flexible flashing system, commonly referred to as a Dektite. This polymer flashing cone is designed to conform to the specific roof profile, whether corrugated, Trimdek, or Klip-Lok. The flashing is secured with fasteners and sealed using neutral-cure silicone to prevent chemical reaction with metal roofing.

Above the flashing, the exhaust cowl is installed on a rigid riser. The cowl design is critical. It must prevent wind-driven rain from entering the duct while allowing unrestricted airflow. Quality designs use internal baffles, downward-facing discharge paths, and insect screens. These features block water, birds, and debris while ensuring moisture-laden air is expelled safely into the atmosphere.

Electrical Safety and Isolation Requirements

Because the motor is located on or above the roof, a thru roof exhaust fan is classified as a remote motor installation. Australian Wiring Rules require a means of local isolation so the fan can be safely serviced.

This is where integration with the Schnap Electric Products ecosystem becomes essential. Lockable isolation switches are typically installed adjacent to the fan or within the ceiling space and within sight of the motor. These weatherproof isolators allow electricians or maintenance personnel to safely disconnect power before cleaning or servicing the fan. Without this local isolation, entire lighting circuits would need to be shut down, disrupting other areas of the home.

Weatherproof isolators used in roof spaces must withstand UV exposure, high heat, and moisture. IP-rated enclosures ensure long-term safety and compliance.

Control Strategies for Moisture Removal

Effective moisture control does not end when the bathroom light is switched off. Steam lingers in the air and is absorbed by towels, tiles, and ceiling surfaces long after use.

Run-on timers are a standard enhancement in professional installations. These devices allow the fan to continue operating for a preset period after the light is turned off. This purge cycle ensures residual humidity is fully evacuated from the room. Typical run-on durations range from five to twenty minutes, depending on room size and usage.

More advanced systems incorporate humidity sensors. These hygrostats automatically activate the fan when relative humidity exceeds a set threshold. Once humidity returns to normal levels, the fan switches off. This automation provides consistent moisture control without relying on occupant behaviour, significantly reducing the risk of mould development over time.

Structural Fixing and Cyclone Considerations

In northern and coastal regions of Australia, wind loading is a serious design consideration. A roof-mounted fan that is not adequately secured can detach during extreme weather events, creating a major safety hazard.

Manufacturers provide specific installation guidelines for high-wind regions. These often include additional fixings, cyclone-rated fasteners, and washers that anchor the flashing plate through the roof sheet and into the underlying battens. The cowl itself must be constructed from UV-stabilised polymers or powder-coated aluminium to resist degradation from heat, salt spray, and airborne debris.

Correct fixing is not only about compliance but also about long-term durability. A securely mounted fan resists vibration, maintains its seal, and continues to operate reliably in harsh conditions.

Noise, Backdrafting, and Performance Integrity

Underpowered roof fans are a common cause of dissatisfaction. In windy conditions, insufficient motor torque can allow air to be forced back down the duct, reintroducing moisture and odours into the room.

Professional-grade thru roof exhaust fans are specified with enough static pressure capability to overcome headwinds and maintain outward airflow. Verified performance curves are essential when selecting a unit. Noise performance is also influenced by impeller balance and mounting integrity. Properly installed systems operate quietly, with most noise contained outside the living space.

Procurement and Quality Assurance

The residential market contains many low-cost roof vents that appear similar but lack the performance and durability required for Australian conditions. These products often use lightweight motors and thin plastics that degrade rapidly under UV exposure.

Tradespeople and contractors source thru roof exhaust fans through electrical wholesaler who verify compliance, performance data, and warranty support. Access to compatible accessories such as isolators, timers, conduit, and rigid ducting ensures the entire system functions as intended.

Conclusion

The thru roof exhaust fan is the most direct and efficient method of moisture extraction in Australian single-storey homes. By minimising static pressure losses, leveraging natural airflow physics, and ensuring robust weatherproofing, it delivers superior ventilation performance. When combined with compliant electrical isolation, intelligent control logic, and quality infrastructure from suppliers such as Schnap Electric Products, it protects both occupant health and the long-term integrity of the building. In residential ventilation, the shortest path to the outside is also the most effective.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products