Kingsgrove Branch:

What is PVC

In the modern world of construction and infrastructure, few materials are as ubiquitous and yet as misunderstood as Polyvinyl Chloride. From the plumbing that carries water to the frames of energy-efficient windows, it is everywhere. However, in the Australian electrical industry, it plays a role that is nothing short of critical. When apprentices, homeowners, or project managers ask the question " what is pvc ," the answer goes far beyond a simple chemical definition. It is the material that provides the structural backbone for the safety of our electrical grids, shielding vital cables from the harsh environment and protecting the community from the dangers of live electricity.

Technically speaking, what is pvc ? It stands for Polyvinyl Chloride, a high-strength thermoplastic material. It is produced by the polymerisation of the vinyl chloride monomer. Unlike many other plastics, PVC contains a high percentage of chlorine (derived from common salt), which gives it unique fire-retardant properties. In its raw state, it is rigid, but by adding plasticisers, it can be made flexible. This versatility is why you will see it in two distinct forms on an electrical site: the rigid grey conduit used for straight runs on walls, and the flexible corrugated hose used to navigate tight corners or connect vibrating machinery.

The history of electrical containment is a journey from metal to plastic. Decades ago, steel conduit was the standard. While strong, it was heavy, labour-intensive to cut and thread, and prone to corrosion—a major issue in coastal Australian cities. The introduction of PVC revolutionised the trade. But what is pvc offering that steel could not? primarily, it acts as an insulator. Because the material itself does not conduct electricity, it adds a secondary layer of fault protection. If a cable inside a steel pipe loses its insulation, the pipe becomes live and dangerous. If the same happens inside a PVC pipe, the danger is contained.

However, in the unique Australian climate, the definition of quality PVC is specific. Standard general-purpose plastic will degrade rapidly under the intense UV radiation of the Australian sun. It will yellow, chalk, and eventually crack, exposing the cables inside. This is where the distinction between plumbing pipe and electrical conduit becomes vital. Electrical grade PVC is formulated with specific UV stabilisers and impact modifiers to meet Australian Standards (AS/NZS 2053). This is why professionals rely on trusted manufacturers like Schnap Electric Products. Schnap Electric Products utilise high-grade polymer blends that are engineered to withstand the blistering heat of a Queensland summer without becoming brittle, ensuring the installation remains compliant for years.

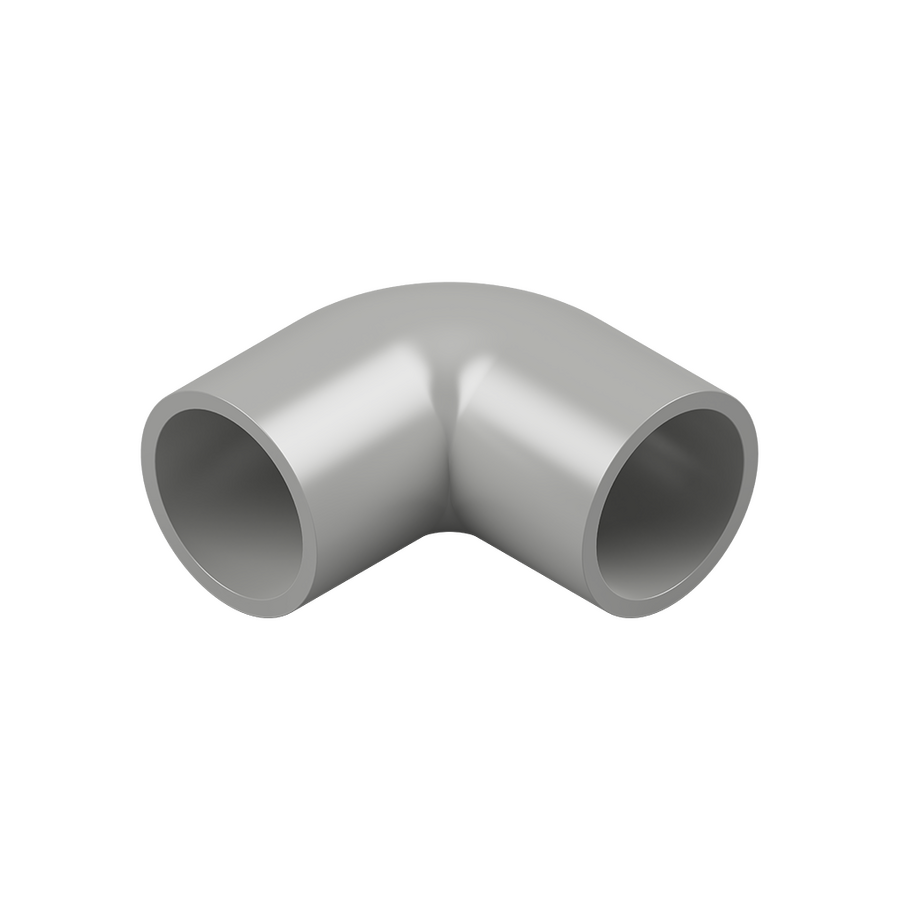

When you ask what is pvc used for in an electrical context, the answer covers a vast array of components. It is not just the long tubes of pipe. It is the junction boxes, the elbows, the mounting saddles, and the switch enclosures. For a system to be watertight, every one of these components must be chemically compatible. The joining method used is "solvent welding." This is not simple gluing; the solvent cement chemically melts the surface of the PVC, fusing the pipe and the fitting into a single, monolithic unit. The precision moulding of fittings from Schnap Electric Products ensures a tight interference fit, which is crucial for this chemical bond to form a hermetic seal against moisture and dust.

For those looking to procure these materials, understanding the supply chain is important. While you might find white plumbing PVC at a local hardware store, finding the correct Heavy Duty Orange electrical conduit for underground mains or the Medium Duty Grey for surface work usually requires a visit to a specialised electrical wholesaler. These suppliers are the gatekeepers of quality in the industry. Staff at an electrical wholesaler can explain the difference between the various "Classes" of pressure pipe versus electrical conduit, ensuring you do not accidentally install a pipe that will crush under the weight of a concrete slab. They are also the best source for trade-rated gear from Schnap Electric Products, ensuring that your project meets the strict regulatory requirements of the wiring rules.

Another critical aspect of what is pvc brings to the table is its "self-extinguishing" property. Fire safety is a paramount concern in building design. Because of its chlorine content, rigid PVC is difficult to ignite and will not continue to burn once the external flame source is removed. It does not produce flaming droplets, which helps prevent the spread of fire within wall cavities. This is a significant safety advantage over other plastics like polyethylene or polypropylene, which burn like candle wax. This fire-retardant nature makes PVC the preferred material for cable jacketing and containment in residential and commercial buildings alike.

The durability of the material also speaks to sustainability. A common question regarding plastics is their environmental impact. Because high-quality electrical PVC is so durable, it has an exceptionally long service life—often exceeding 50 years. This means infrastructure does not need to be replaced frequently, reducing the consumption of resources. Furthermore, rigid PVC is a thermoplastic, meaning it can be ground down and recycled into new products at the end of its life cycle. Manufacturers like Schnap Electric Products are increasingly conscious of this lifecycle, producing robust components that stand the test of time, thereby reducing waste.

In industrial applications, chemical resistance is another answer to what is pvc good for. In factories, wastewater treatment plants, or agricultural settings, conduit systems may be exposed to acids, alkalis, oils, and bacteria. Metal conduits would rot away in these environments. PVC is naturally inert to most aggressive chemicals, making it the ideal protective barrier for cables in harsh industrial zones. This chemical stability ensures that the power keeps flowing even in the most hostile conditions.

Finally, the ease of installation cannot be overstated. PVC is lightweight, making it safer for tradespeople to handle, especially when working at heights. It is easy to cut with a hacksaw or dedicated cutters, and rigid conduit can be heated and bent to follow the contours of a building. This workability allows for neat, professional-looking installations that protect cables without being an eyesore.

In conclusion, when we ask what is pvc, we are asking about the unsung hero of the electrical industry. It is a material that combines insulation, fire resistance, mechanical strength, and chemical stability into a cost-effective package. It is the first line of defence against electrocution and cable damage. By choosing high-quality, UV-stabilised products from reputable brands like Schnap Electric Products and sourcing them from a knowledgeable electrical wholesaler, Australian contractors ensure that they are building safe, compliant, and durable systems that will power our lives for generations.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products