Kingsgrove Branch:

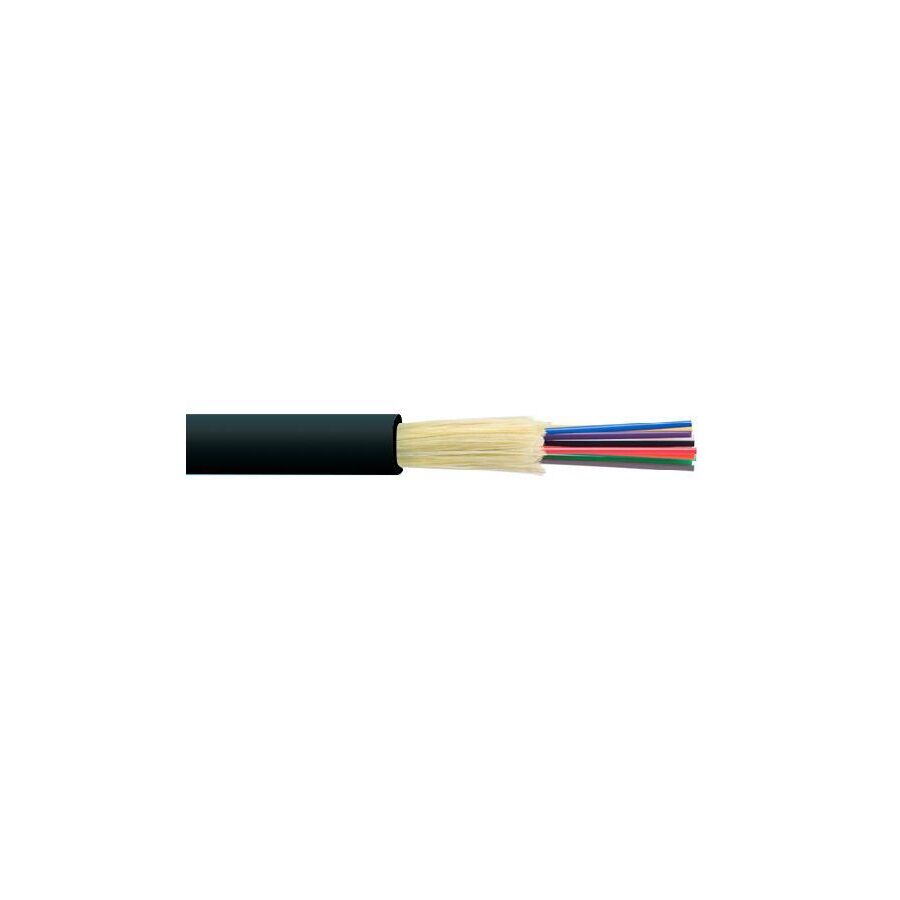

12 Core OM3 Fibre Cable

In modern Australian data network architecture, bandwidth demand within vertical risers, campus backbones, and inter-building links has exceeded the practical limits of copper cabling. While Category 6A copper can support 10 Gigabit Ethernet over short distances, it remains vulnerable to electromagnetic interference and is limited to a maximum operational length of 100 metres. For connecting server rooms, floor distributors, communications rooms, and edge cabinets across commercial buildings or industrial facilities, optical fibre has become the engineering standard.

Within this environment, 12 Core OM3 Fibre Cable has emerged as the baseline specification for enterprise-grade backbone infrastructure. This configuration delivers an optimal balance between fibre density, upgrade flexibility, and cost efficiency for link lengths up to 300 metres, making it ideally suited to Australian commercial buildings, campuses, and industrial sites.

The Physics of Laser-Optimised Multimode Fibre

The designation OM3 stands for Optical Multimode 3, a fibre classification defined under ISO/IEC 11801. Earlier multimode generations such as OM1 and OM2 were designed for LED light sources and are unsuitable for modern high-speed networks. OM3 fibre is specifically engineered for use with Vertical-Cavity Surface-Emitting Lasers (VCSELs) operating at the 850nm wavelength.

The critical performance parameter is Effective Modal Bandwidth (EMB). OM3 fibre provides an EMB rating of 2000 MHz·km, achieved through a precisely controlled refractive index profile within the 50-micron glass core. This profile minimises Differential Mode Delay (DMD), which occurs when light pulses travel multiple paths within the fibre and arrive at the receiver at different times. By reducing modal dispersion, OM3 fibre supports stable 10Gbps transmission over distances up to 300 metres, comfortably covering the vast majority of Australian commercial riser and campus backbone applications.

Why Twelve Cores? Strategic Fibre Density

Specifying a 12-core fibre cable is a deliberate engineering decision. In standard duplex Ethernet communication, one fibre transmits data and one fibre receives data, meaning a 12-core cable can support six independent 10GbE links using LC connectors. This alone provides ample capacity for most commercial deployments.

The greater strategic advantage lies in parallel optics. Emerging standards such as 40GBASE-SR4 and 100GBASE-SR4 utilise MPO or MTP connectors that engage 8 or 12 fibres simultaneously to form a single high-bandwidth channel. By installing a 12-core OM3 backbone today, facility managers effectively future-proof their infrastructure, enabling 40Gbps and 100Gbps upgrades without the need to re-cable risers, ceiling spaces, or underground pathways.

Cable Construction: Loose Tube vs Tight Buffered

The internal construction of a fibre cable must be selected based on the installation environment. Loose tube construction houses 250-micron coated fibres within a gel-filled or dry-blocked buffer tube, isolating the glass from mechanical stress and thermal expansion. This design is well suited to inter-building links, warehouses, indoor-outdoor transitions, and non-climate-controlled environments.

For vertical risers and strictly indoor applications, tight buffered construction is preferred. Each fibre is coated with a 900-micron buffer, providing greater mechanical protection and allowing direct termination inside patch panels and fibre trays. Regardless of construction type, Australian commercial installations typically require a Low Smoke Zero Halogen (LSZH) outer jacket. LSZH materials do not emit toxic gases or dense smoke during fire events and are mandatory for egress paths under the National Construction Code.

Termination and FOBOT Integration

The termination point of a multi-core backbone is one of the most critical areas for long-term reliability. This transition occurs at the Fibre Optic Break Out Tray (FOBOT), where the heavy external cable separates into individual fibres or pigtails. Proper strain relief and bend-radius control at this point are essential to prevent attenuation and premature failure.

This is where Schnap Electric Products integrates into the passive optical network. Schnap Electric Products supplies industrial-grade 19-inch rack enclosures and fibre trays engineered for high-density backbone termination. A 12-core OM3 cable requires a splice cassette capable of housing 12 fusion splice protectors, with sufficient tray depth and routing spools to maintain compliant bend radii. Cable gland systems secure the aramid yarn strength members to the steel enclosure, ensuring any external pulling force is absorbed by the rack rather than the glass fibres.

Installation Physics: Tension and Bend Radius

Optical fibre exhibits high tensile strength but is vulnerable to shear damage and micro-fractures. During installation, maximum pulling tension must be strictly observed. A typical 12-core OM3 cable has an installation tension limit between 1000N and 1500N. Exceeding this threshold stretches the glass, creating microscopic cracks that degrade signal integrity over time.

Bend radius discipline is equally important. A common engineering rule specifies a minimum bend radius of 20 times the cable diameter during installation and 10 times the diameter once the cable is fixed in place. Sharp bends cause macrobend loss, allowing light to escape the core and reducing available link margin.

Procurement and Supply Chain Assurance

The quality of fibre glass and jacket extrusion cannot be assessed visually. Inferior fibre may suffer from high attenuation, inconsistent core geometry, or brittle jackets that crack during installation. To ensure backbone integrity, communications consultants and data contractors procure fibre through specialised electrical wholesalers with dedicated data infrastructure divisions.

Professional suppliers verify RCM compliance, fire-rating suitability, and adherence to ISO/IEC standards. They also ensure compatibility with Australian building classifications and maintain stock of fusion splice consumables, labels, and accessories, supporting compliance with AS/NZS 3080 and AS/ACIF S009.

Conclusion

The 12-core OM3 fibre cable remains the backbone of Australian commercial data infrastructure. It delivers the bandwidth required for today’s 10GbE networks while preserving capacity for future parallel-optics upgrades. By understanding modal dispersion physics, selecting the correct construction type, and terminating within mechanically robust infrastructure from suppliers such as Schnap Electric Products, engineers can deploy networks that are fast, scalable, and compliant. In the digital economy, the quality of the glass ultimately determines the speed of business.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products