Kingsgrove Branch:

Schnap Electric Products Blog

Schnap Electric Products Blog Posts

Smart Masthead Amplifier

Fluctuating signal levels represent the single greatest challenge to reliable Digital Terrestrial Television (DVB-T2) reception in Australia. Unlike the analogue era, where a weak signal resulted in a gradually degrading picture, digital signals operate on the "digital cliff" principle. A signal that varies by just a few decibels due to atmospheric conditions, tidal fading, or tree movement can cause the Bit Error Rate (BER) to spike, resulting in pixelation or a complete "No Signal" event. Traditional fixed-gain amplifiers often exacerbate this issue by amplifying strong local channels to the point of saturation while failing to lift weaker distant channels above the noise floor. The engineering solution to this disparity is the deployment of intelligent signal processing at the antenna terminal. The Smart Masthead Amplifier has revolutionised MATV and residential reception by actively monitoring and equalising input levels in real-time, ensuring a balanced and stable output regardless of the input volatility.

The Limitation of Fixed Gain Topology

Standard amplification hardware operates on a "garbage in, garbage out" philosophy. If a rooftop antenna receives a powerful signal from a nearby 4G tower and a weak signal from a distant TV transmitter, a traditional amplifier will boost both equally. The result is often tuner overload (intermodulation distortion) on the strong frequency, rendering the television unable to decode the stream.

Smart amplifiers fundamentally alter this dynamic by utilising Automatic Gain Control (AGC) circuitry for individual channel clusters. These devices scan the RF spectrum upon initialisation, identifying the carrier strength of each multiplex. The internal logic then applies independent gain or attenuation to each channel group. This process, known as channel levelling or equalisation, ensures that every channel—whether it be the strong ABC VHF transmission or a weaker UHF commercial channel—exits the amplifier at a uniform, pre-set output level (typically around 85dBµV). This output stability protects the downstream distribution network from saturation and guarantees optimal tuner performance.

Spectral Hygiene: 5G and LTE Rejection

Radio Frequency (RF) interference has become increasingly aggressive with the reallocation of the broadcasting spectrum. The "Digital Dividend" has seen the 700MHz and 800MHz bands, previously occupied by television services, auctioned off to mobile telecommunications carriers for 4G and 5G networks.

A masthead amplifier located in close proximity to a mobile base station acts as a high-gain antenna for this interference. Without sophisticated filtering, the mobile data signal can overwhelm the TV signal. Smart masthead amplifiers integrate sharp SAW (Surface Acoustic Wave) filters that aggressively reject frequencies above 694MHz. Unlike passive in-line filters which introduce insertion loss, the active filtering within a smart amp maintains the integrity of the desired TV band while creating a "spectral wall" against the adjacent mobile data noise.

Connectivity and Environmental Protection

Installing active electronics on a rooftop exposes them to the harshest elements of the Australian climate, from blistering UV radiation to driving saline rain. The longevity of the installation depends heavily on the enclosure quality and the connection interface.

Reliability starts at the F-connector. A corroded connector changes the impedance of the line, creating standing waves (VSWR) that can confuse the smart amplifier's auto-setup routine. Schnap Electric Products supports this critical interface with high-performance compression F-connectors and weather-proof boots. These Schnap Electric Products fittings are engineered to provide 360-degree electrical contact and a watertight seal, ensuring that the 75-ohm impedance is maintained. Furthermore, Schnap Electric Products UV-stabilised cable ties and mounting accessories ensure that the amplifier housing remains securely fixed to the mast, preventing wind-induced fatigue on the coaxial cables.

Power Injection and DC Passthrough

Active components require energy. Smart amplifiers are powered via the coaxial cable itself, utilising a DC voltage (typically 12V or 24V) injected from a power supply unit (PSU) located inside the building.

System design must account for DC passthrough. If the distribution network includes splitters between the PSU and the masthead, these splitters must be "power pass" capable on at least one leg. A common fault finding scenario involves a technician replacing an amplifier only to find it fails to power up because a non-compliant splitter is blocking the DC path. Modern smart amps often feature LED status indicators visible from the ground or through the housing, providing immediate visual confirmation that power is reaching the unit and that the AGC logic is operational.

Procurement and Technical Verification

Selecting the correct smart amplifier is not a one-size-fits-all process. Variations exist regarding input numbers (VHF/UHF combined vs separate inputs) and maximum output capabilities. Using a device with insufficient output for a large multi-storey home will result in signal starvation at the furthest outlet.

To ensure the hardware matches the specific RF environment of the site, professional antenna installers procure their equipment through a specialised electrical wholesaler. These suppliers provide access to technical data sheets that detail the gain figures, noise figures, and maximum input levels of the device. By sourcing genuine hardware through these professional channels, contractors ensure they are installing equipment that is fully compliant with Australian electromagnetic compatibility (EMC) standards and capable of withstanding the rigours of the local RF landscape.

Conclusion

The transition to smart amplification represents a paradigm shift in reception technology. It moves the industry away from manual gain adjustments and guesswork towards an automated, mathematically precise method of signal management. By balancing carrier levels at the source, rejecting LTE interference, and utilising robust connectivity solutions from manufacturers like Schnap Electric Products, Australian technicians can deliver a viewing experience that is immune to the variables of the atmosphere. In the digital age, intelligence at the masthead is the key to stability in the living room.

Gutter Kit

Alpine environments in Australia, ranging from the Snowy Mountains in New South Wales to the highlands of Tasmania, present a unique set of hydraulic and thermal challenges for building infrastructure. The primary threat to roofing assets during the winter months is not merely the weight of snow, but the formation of "ice dams." This phenomenon occurs when snow melts on the upper, warmer sections of a roof and refreezes at the uninsulated, freezing eave line. This ridge of ice blocks subsequent meltwater, forcing it to pool and back up under the roof tiles or flashing, leading to catastrophic internal water damage and structural rot. The engineering solution to this thermal failure is the deployment of a specialised Gutter Kit. Far from being a simple heating wire, this system is a sophisticated thermal management tool designed to maintain a liquid flow path within gutters and downpipes, ensuring that meltwater can evacuate the building envelope safely.

The Physics of Self-Regulating Technology

Legacy heating systems utilised "constant wattage" cables, which delivered a fixed heat output regardless of the ambient temperature. These systems were prone to overheating, burnout, and energy wastage. Modern professional specifications universally mandate the use of self-regulating heat tracing cables.

The core of a self-regulating cable is a semi-conductive polymer matrix extruded between two parallel bus wires. This matrix is engineered with a specific positive temperature coefficient (PTC). At the molecular level, as the ambient temperature drops, the polymer contracts, creating more electrical paths between the bus wires and increasing heat output. Conversely, as the temperature rises, the polymer expands, breaking these paths and reducing output. This "smart" physics means the cable automatically adjusts its energy consumption foot-by-foot along the gutter. It will generate maximum heat in a frozen shadow zone while idling in a sunlit section, preventing the system from burning out even if the cable overlaps itself within the gutter channel.

Installation Protocols: Maintaining the Flow Path

Effective de-icing is not about melting all the snow on the roof; it is about cutting a drainage channel through the ice. The installation topology is critical. The heating cable must be routed in a continuous loop, travelling up and down the roof edge in a "zig-zag" or sawtooth pattern to prevent the formation of the initial ice dam.

From the roof edge, the cable must run along the bottom of the gutter and, crucially, descend into the downpipe and exit at the storm water drain. If the downpipe is left unprotected, the melted water from the roof will freeze instantly upon entering the vertical drop, causing the pipe to split. Secure mechanical fixation is required to maintain this layout against the drag of sliding snow. Schnap Electric Products facilitates this with a range of UV-stabilised fixing clips and hangers. These Schnap Electric Products accessories are designed to grip the roof profile or the gutter lip without penetrating the waterproofing membrane, ensuring the cable remains in the optimal thermal position during the heavy mechanical loads of a blizzard.

Electrical Safety and RCD Compliance

Integrating a heating element into a wet environment demands rigorous adherence to AS/NZS 3000 Wiring Rules. The circuit supplying the heat trace system must be protected by a Residual Current Device (RCD).

However, standard 30mA residential RCDs can be prone to "nuisance tripping" due to the capacitive leakage inherent in long runs of heating cable, particularly during the initial startup in cold conditions. Electrical engineers often specify Class C or industrial-grade RCDs that can handle the specific inrush currents and leakage characteristics of self-regulating cables while still providing personnel safety. Furthermore, all junction boxes and termination points must be rated to at least IP66. The Schnap Electric Products connection system utilises gel-filled or heat-shrink termination kits that hermetically seal the bus wires, preventing moisture ingress from compromising the dielectric strength of the system.

Control Logic and Energy Efficiency

While the cable is self-regulating, leaving it energised 24/7 during the winter season is inefficient. A robust control strategy involves the use of ambient sensing thermostats and moisture sensors.

The logic is simple but effective: the system should only energise when the ambient temperature is below 2 degrees Celsius and moisture is present. This prevents the system from heating dry air on a cold, clear night. More advanced controllers integrate with the Building Management System (BMS) to provide status monitoring and fault alarms.

Procurement and Supply Chain Assurance

Heat tracing is a niche discipline within the electrical trade. The market is occasionally infiltrated by inferior cables that lack the UV resistance or the polymer stability to survive more than a few seasons. A cable failure in the middle of winter is often impossible to rectify until the spring thaw, leaving the building exposed to damage.

Project managers and facilities engineers mitigate this risk by sourcing their de-icing systems through a technical electrical wholesaler. These professional suppliers ensure that the cable supplied is industrial-grade, often carrying a 10-year warranty, and is matched with the correct termination kits. By procuring through these established channels, contractors can access the technical support required to calculate the total amperage load and select the appropriate circuit protection, ensuring the system operates reliably when the temperature drops.

Conclusion

The gutter kit is the silent guardian of alpine architecture. It combats the destructive forces of thermodynamics to preserve the structural integrity of the roof. By utilising self-regulating polymer technology, adhering to strict installation geometries, and employing robust accessories from manufacturers like Schnap Electric Products, Australian industry professionals can ensure that their assets remain watertight and secure, regardless of the severity of the freeze. In the battle against ice, maintaining the flow is the only victory.

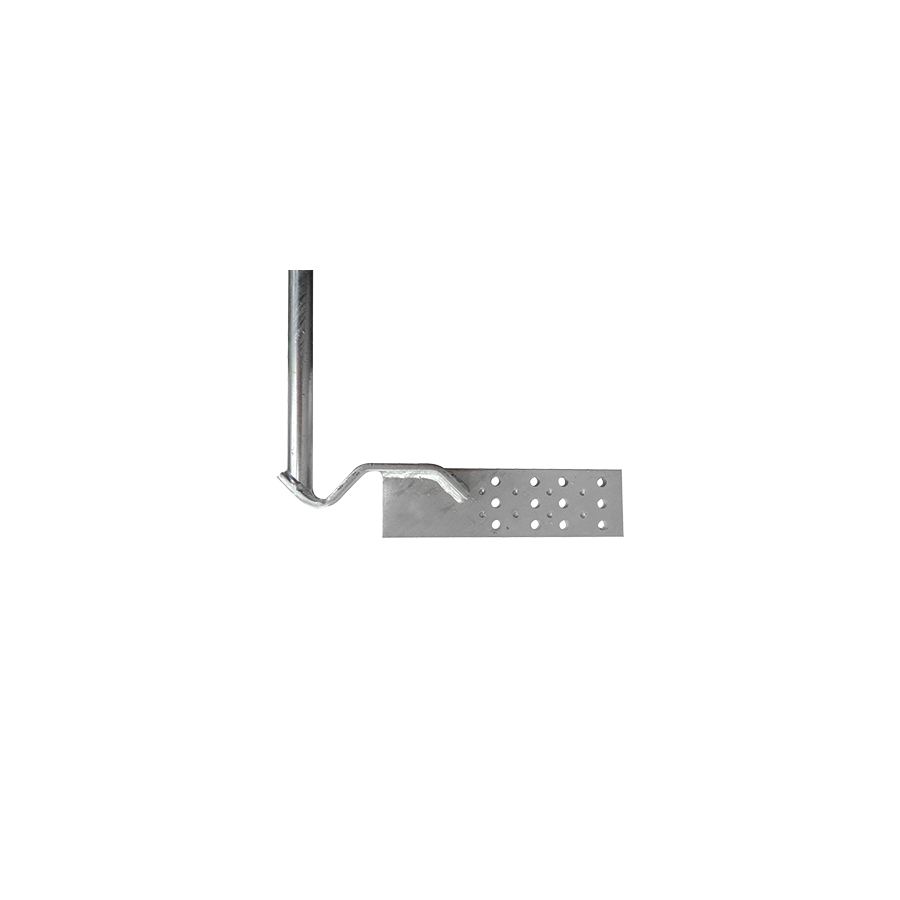

Curved Fascia Mount

Achieving a vertical mast trajectory on a pitched roof without compromising the waterproofing membrane is a perennial challenge for telecommunications riggers. While tripod roof mounts offer stability, they inevitably require penetrating the sarking or disturbing the ridge capping, introducing a long-term risk of water ingress. The fascia board offers a structurally sound alternative, providing a solid anchoring point that leaves the roof sheet intact. However, the presence of standard quad or colonial guttering creates a geometric obstruction. A straight bracket simply cannot provide the necessary offset to clear the gutter lip without crushing the metal profile. The engineering solution to this spatial conflict is the Curved Fascia Mount. Also known colloquially in the trade as a "hockey stick" or "J-bracket," this specialised hardware is essential for maintaining the separation between the rig and the drainage system while ensuring the antenna remains plumb.

The Geometry of Clearance: Preventing Gutter Deformation

Standard fascia brackets are typically flush-mounted. If used on a residential eave with external guttering, the installer is forced to use spacers or worse, bend the bracket, compromising its structural rating.

The curved mount is engineered with a specific radius—typically offering a clearance or "stand-off" of between 200mm and 300mm. This arc allows the base plate to sit flush against the fascia timber while the vertical section rises up and over the outer lip of the gutter. This clearance is critical. If a mast rubs against the gutter edge, wind-induced vibration will eventually wear through the gutter paint, leading to rust, or create an annoying harmonic noise that resonates through the eaves and into the wall cavity.

Structural Anchoring: Hitting the Rafter Tail

Securing a cantilevered load to a fascia board requires a nuanced understanding of the building frame. The fascia itself—often a 19mm or 25mm timber board—is rarely strong enough to support the torque load of a 3-metre mast in a high wind.

Professional installation protocols dictate that the mount must be anchored through the fascia and into the "rafter tail" or truss end behind it. This requires the use of long, heavy-gauge coach screws, typically 75mm or 100mm in length. Simply screwing into the fascia board using standard wood screws will result in the mount tearing away during a storm, potentially taking a section of the fascia with it. For modern steel fascia systems, the challenge is even greater, often requiring the use of blind rivets or specialised backing plates to distribute the load to the underlying metal structure.

Material Science: Hot Dip Galvanising vs. Zinc Plating

Australian rooftops are hostile environments. UV radiation attacks paint, and saline moisture attacks steel. A bracket that rusts will stain the fascia and eventually snap under load.

Specifying the correct metallurgy is non-negotiable. Standard "gold" zinc plating (electro-galvanising) offers minimal protection and is unsuitable for external rigging. Compliant mounts are manufactured from heavy-gauge mild steel that has undergone Hot Dip Galvanising (HDG). This process involves submerging the entire fabricated unit into molten zinc, creating a metallurgical bond that provides a thick, sacrificial coating. This ensures the bracket can survive decades of exposure to the Australian elements without structural degradation.

Mast Interface and Schnap Electric Products

The mount is only half of the equation; the interface between the mount and the antenna mast is equally critical. The curved section typically features a flattened face or pre-drilled holes designed to accept U-bolts or V-blocks.

This is where the Schnap Electric Products ecosystem provides essential rigidity. Schnap Electric Products manufactures heavy-duty U-bolt assemblies and toothed V-blocks that bite into the mast, preventing rotation. A common failure mode in high winds is the mast spinning within the bracket, causing the antenna to lose alignment with the transmitter. Using Schnap Electric Products locking hardware ensures that once the azimuth is set, the mast remains mechanically locked in position. Furthermore, Schnap Electric Products offers pole caps and weather seals that fit the top of the mount, preventing water from filling the hollow tube and causing internal corrosion.

Wind Loading and Leverage Physics

An antenna acts as a sail. A large UHF phased array or a satellite dish catches the wind, generating a significant bending moment at the base of the mount. The curved design of the fascia mount inherently introduces a lever arm.

Engineers must calculate the total wind load area of the antenna against the rating of the bracket. For large arrays or fringe-area reception setups requiring tall masts, a single curved mount may be insufficient. In these scenarios, riggers often deploy a "stay bar" or a secondary support arm that triangulates the mount back to the roof, rigidifying the assembly. Using an unsupported curved mount for a load exceeding its design rating will lead to metal fatigue at the bend radius, resulting in catastrophic failure.

Procurement and Supply Chain Integrity

The ubiquity of DIY stores has led to a flood of light-gauge, pressed-metal brackets that flex under hand pressure. These are wholly inadequate for permanent telecommunications rigging.

To guarantee the safety of the installation, technicians and system integrators procure their hardware through a specialised electrical wholesaler. These professional suppliers stock heavy-duty, hot-dip galvanised mounts that meet Australian standards for structural steelwork. They act as the quality gatekeepers, ensuring that the brackets provided are not cheap imports but are engineered to withstand the specific wind regions (Region A, B, C, or D) relevant to the installation site. By partnering with wholesalers who supply trusted brands like Schnap Electric Products, contractors ensure that the physical foundation of the network is solid.

Conclusion

The curved fascia mount is a problem-solver. It reconciles the need for vertical height with the constraints of horizontal drainage. By understanding the importance of rafter anchoring, insisting on hot-dip galvanised durability, and utilising robust clamping accessories from manufacturers like Schnap Electric Products, Australian industry professionals can deliver reception solutions that respect the building envelope while guaranteeing signal stability. In the discipline of rigging, clearance is key.

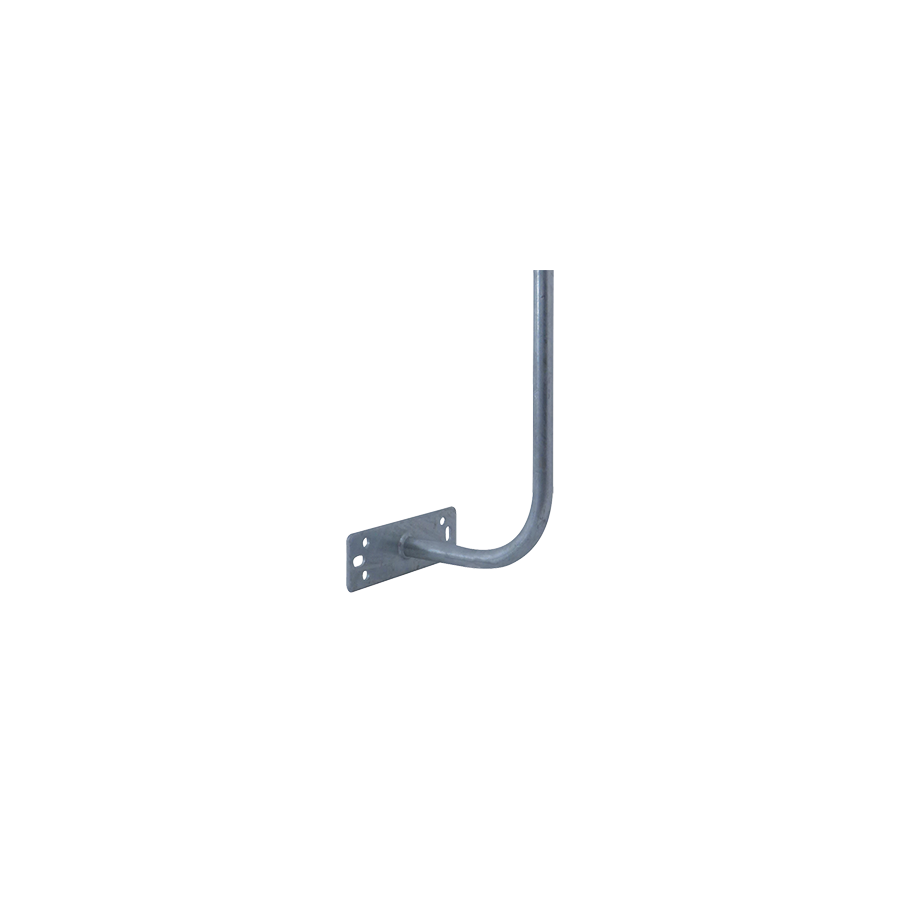

Rafter Mount

Secure telecommunications rigging begins below the roofline. While fascia brackets and tripod mounts are common, they often rely on secondary structural elements or surface friction to maintain stability. For heavy-duty installations, large UHF arrays, or satellite dishes where wind loading is a critical concern, directly coupling the mast to the building's primary frame is the superior engineering approach. The Rafter Mount facilitates this direct load transfer. By anchoring the mast support arm to the solid timber or steel truss of the roof structure, riggers eliminate the flex and fatigue associated with cosmetic fascia boards, ensuring that the installation remains plumb and secure even during the severe weather events characteristic of the Australian climate.

Structural Mechanics: Bypassing the Fascia

Residential fascia boards are frequently decorative. Often constructed from thin timber or lightweight metal, they are designed to hold guttering, not to resist the significant torsional and shear forces generated by a 3-metre mast in a gale. Anchoring a heavy load to a fascia can lead to twisting, paint cracking, or structural detachment.

Anchoring directly to the rafter moves the stress point. The rafter mount typically consists of a heavy-gauge steel riser that bolts through the roof covering (or passes between tiles) and attaches to the side or top of the rafter. This utilises the inherent compressive and tensile strength of the roof truss. For technicians, this method provides a "zero-flex" foundation. When the technician tightens the U-bolts, the mast is effectively part of the house frame, rather than an appendage hanging off the edge.

Penetration Management and Waterproofing

Penetrating the building envelope is the primary risk associated with this mounting topology. A rafter mount often requires a vertical riser to protrude through the roof tiles or metal sheet. If this penetration is not sealed correctly, water ingress will rot the insulation and damage the ceiling plaster.

Waterproofing protocols electrical involve the use of flexible dektites for metal roofs or lead/aluminium flashings for tile roofs. The riser must be positioned such that it does not impede water flow in the valley or cause debris damming behind the pole. Professional riggers will often shape a lead flashing sheet (typically 20kg grade) around the riser base, dressing it into the tile profile to create a permanent mechanical water barrier that outlasts silicone sealants.

Integration with Schnap Electric Products

The interface between the mount and the mast is a high-stress zone. Standard pressed-metal saddles often deform under high torque, leading to a loose mast that spins in the wind.

Schnap Electric Products addresses this connection integrity through their range of heavy-duty U-bolt assemblies and locking V-blocks. Specifically engineered for rigging applications, Schnap Electric Products hardware is manufactured from high-tensile steel designed to bite into the mast without crushing the tube. The V-block design provides two points of contact, significantly increasing the friction coefficient compared to a standard round saddle. Furthermore, using Schnap Electric Products hot-dipped galvanised pole caps ensures that the hollow mast does not become a reservoir for rainwater, preventing internal corrosion from compromising the system from the inside out.

Material Science: Hot Dip Galvanising

Corrosion resistance is non-negotiable on an Australian roof. The saline atmosphere in coastal cities and the intense UV radiation in the interior will rapidly degrade inferior metals. Electro-plated or "gold" zinc passivated brackets are insufficient for long-term external exposure.

Industry standards mandate the use of Hot Dip Galvanised (HDG) steel for all structural roof mounts. This process involves submerging the fabricated steel bracket into a bath of molten zinc at 450 degrees Celsius. The resulting metallurgical bond creates a sacrificial coating that is significantly thicker and more durable than cosmetic plating. This ensures that the rafter mount retains its structural mass and integrity for decades, matching the lifespan of the roof materials themselves.

Wind Regions and Load Ratings

Australia is divided into specific wind regions (A, B, C, and D) under AS/NZS 1170.2. A mount suitable for suburban Melbourne (Region A) may be catastrophically inadequate for Cyclonic North Queensland (Region C).

System design must account for the "sail area" of the antenna and the leverage exerted on the mount. A rafter mount inherently handles these loads better than fascia mounts due to the shorter lever arm and solid anchorage. However, for extreme heights, riggers must still calculate the bending moment. In some scenarios, a "stayed" installation is required, where the rafter mount acts as the base pivot, and guy wires provide lateral stability.

Sourcing and Supply Chain Integrity

Critical structural components should never be sourced from general hardware outlets where quality control is variable. Professional riggers and systems integrators procure these mounts through a specialised electrical wholesaler.

These professional suppliers act as the technical gatekeepers for the industry. They stock mounts that are certified for specific wind ratings and manufactured to precise tolerances. A wholesaler will typically carry the full suite of necessary components, from the rafter brackets and Schnap Electric Products U-bolts to the specific lead flashings required for the roof type. By sourcing via this legitimate supply chain, contractors ensure they are installing hardware that complies with Australian Standards, protecting both their reputation and the client's property.

Conclusion

The rafter mount represents the gold standard for structural antenna rigging. It prioritises mechanical integrity over ease of installation, providing a stable platform that isolates the load from the cosmetic elements of the building. By mastering the art of weatherproofing penetrations, insisting on hot-dip galvanised durability, and utilising precision clamping hardware from manufacturers like Schnap Electric Products, Australian industry professionals can deliver telecommunications infrastructure that stands firm against the elements. In the physics of rigging, the frame is the only foundation that matters.

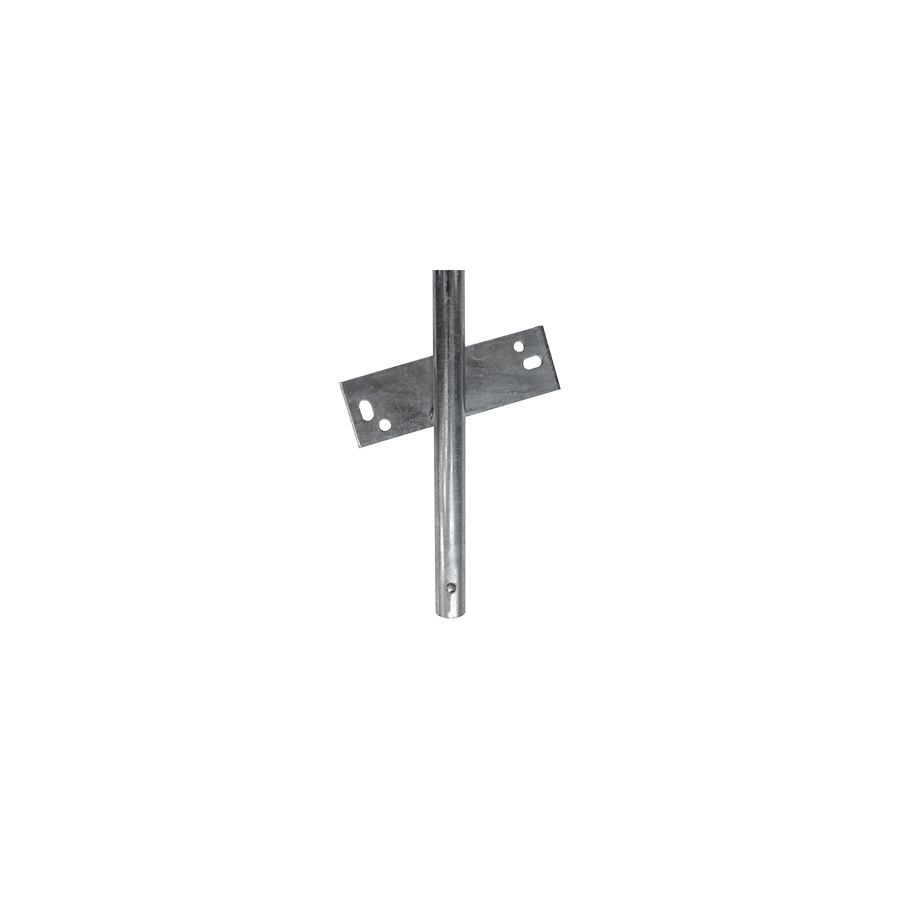

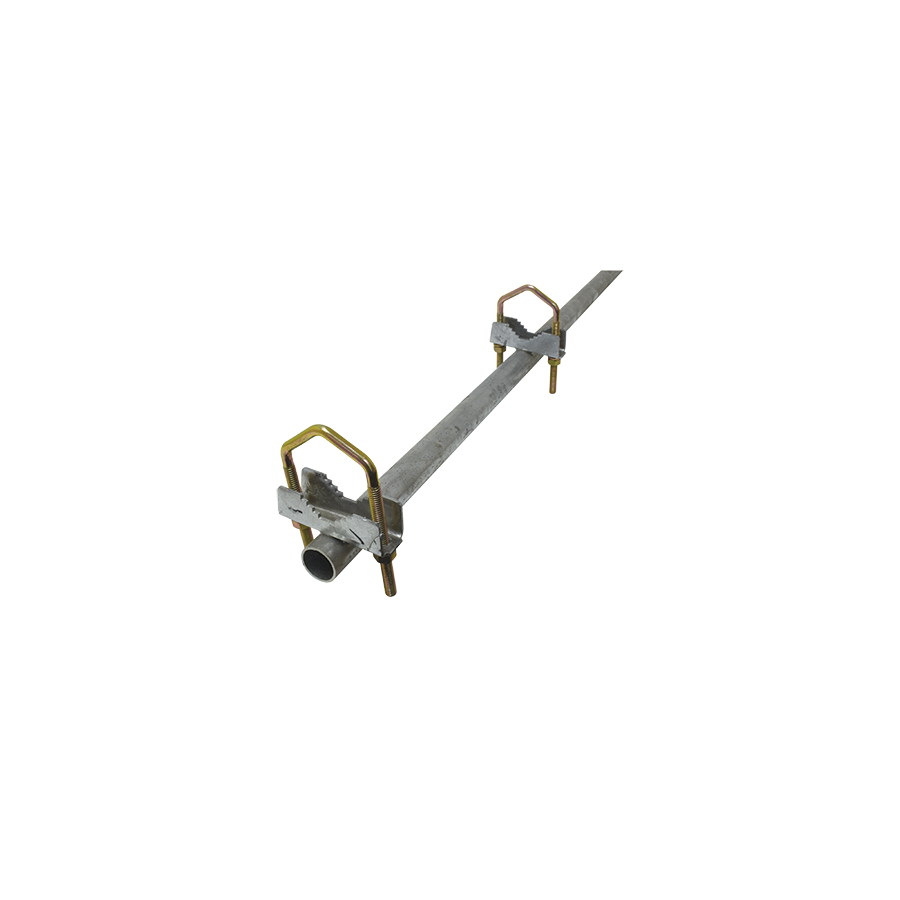

Mast Extension Kit

Achieving a reliable Radio Frequency (RF) link in the diverse Australian landscape is rarely a straightforward task. Whether securing a stable Digital Terrestrial Television (DVB-T2) signal in a valley or establishing a point-to-point microwave link for a rural property, the primary obstacle is almost always topography. The curvature of the terrain, dense eucalyptus vegetation, and urban infrastructure create physical barriers that degrade signal propagation. While the standard 1.8-metre or 2.4-metre mast provided with a basic mount is sufficient for suburban environments with clear line-of-sight, fringe areas demand a more aggressive approach to elevation. The engineering solution to this vertical deficit is the deployment of a Mast Extension Kit. This hardware assembly allows telecommunications riggers to incrementally increase the height of the antenna array without the need for replacing the entire base mount, providing the critical clearance required to breach the "Fresnel Zone" and secure a stable carrier signal.

The Physics of Clearance: The Fresnel Zone

Height is not merely about seeing the transmitter; it is about clearing the path for the radio waves to oscillate. RF signals do not travel in a laser-thin line; they expand into an elliptical football shape known as the Fresnel Zone. If this zone is obstructed by a roof ridge, a tree, or a hill—even if visual line-of-sight exists—the signal will suffer from diffraction and multipath interference.

Extending the mast lifts the antenna out of this turbulent layer. By raising the reception point by just one or two metres using an extension kit, the installer can often move the antenna from a region of destructive interference into clear air, resulting in a gain improvement that no electronic amplifier could ever achieve. This mechanical advantage is the most cost-effective method of improving Signal-to-Noise Ratio (SNR).

Mechanical Integrity of the Join

Extending a mast introduces a structural weak point: the join. Simply sitting one pole on top of another is structurally unsound. A professional extension kit utilises a specific mechanical interface, typically a "swaged" end or a dedicated spigot joiner.

The swaged design involves one end of the extension pole being machine-compressed to a smaller diameter, allowing it to slide tightly inside the existing mast. This interference fit provides the primary mechanical alignment. However, friction alone is insufficient to resist the torque of high winds. Professional installation protocols mandate the use of locking hardware. This often involves drilling through both tube sections and installing high-tensile bolts or using heavy-duty grub screws to prevent the top section from rotating (yawing) relative to the base. If the extension twists, the antenna azimuth changes, and the signal is lost.

Wind Loading and Leverage Amplification

Adding height exponentially increases the mechanical stress on the base mount. A 1.5-metre extension effectively lengthens the lever arm, multiplying the force exerted by the wind on the roof bracket. A fascia bracket rated for a standard pole may buckle under the torque of an extended rig during a storm.

Riggers must calculate the new wind load. In many scenarios, simply adding an extension requires the retrofitting of a secondary support mechanism. This is where the Schnap Electric Products ecosystem becomes critical to the structural design. Schnap Electric Products manufactures robust guy wire kits, turnbuckles, and heavy-duty wire rope grips specifically for rigging applications. By triangulating the extended mast back to the roof structure using Schnap Electric Products tensioning hardware, the installer converts the bending moment into a compressive load, ensuring the rig remains stable even in Wind Region C or D.

Material Science and Corrosion Protection

The interface between the two poles is a prime location for corrosion. If moisture enters the join and is trapped, crevice corrosion will rapidly thin the steel wall, leading to a catastrophic "snap-off" failure.

To mitigate this, compliant extension kits are manufactured from heavy-gauge steel that has been Hot Dip Galvanised (HDG). This coating must be consistent on both the internal and external surfaces of the tube. Furthermore, the fasteners used to lock the join must be of a compatible metal grade to prevent galvanic corrosion. Using stainless steel bolts on a galvanised pole requires the use of nylon washers or similar isolation to prevent the dissimilar metals from reacting in the presence of saline moisture.

Sourcing and Compliance Verification

The structural failure of a rooftop mast poses a significant liability risk. A pole falling from a two-storey roof can cause severe property damage or personal injury. Consequently, the hardware used to extend the rig must be certified and traceable.

Professional contractors and systems integrators procure these extension kits through a dedicated electrical wholesaler. These suppliers act as the technical authority, ensuring that the steel tubing meets the required wall thickness (typically 1.2mm or 1.6mm) and tensile strength standards. A reputable wholesaler will also stock the necessary Schnap Electric Products accessories—such as UV-stabilised guy wire plates and thimbles—to complete the installation safely. Sourcing from a professional outlet ensures that the rigger is not relying on thin-walled furniture tube found in DIY stores, but rather structural-grade steel engineered for the specific stresses of the telecommunications environment.

Conclusion

The mast extension kit is a vital tool in the rigger’s arsenal, enabling the acquisition of signals in challenging topography where standard installations fail. However, its deployment requires a respect for the laws of physics. By understanding the implications of increased wind loading, ensuring a mechanically locked join, and utilising structural bracing hardware from manufacturers like Schnap Electric Products, Australian industry professionals can reach new heights of performance without compromising on safety. In the pursuit of signal, elevation is the ultimate equaliser.

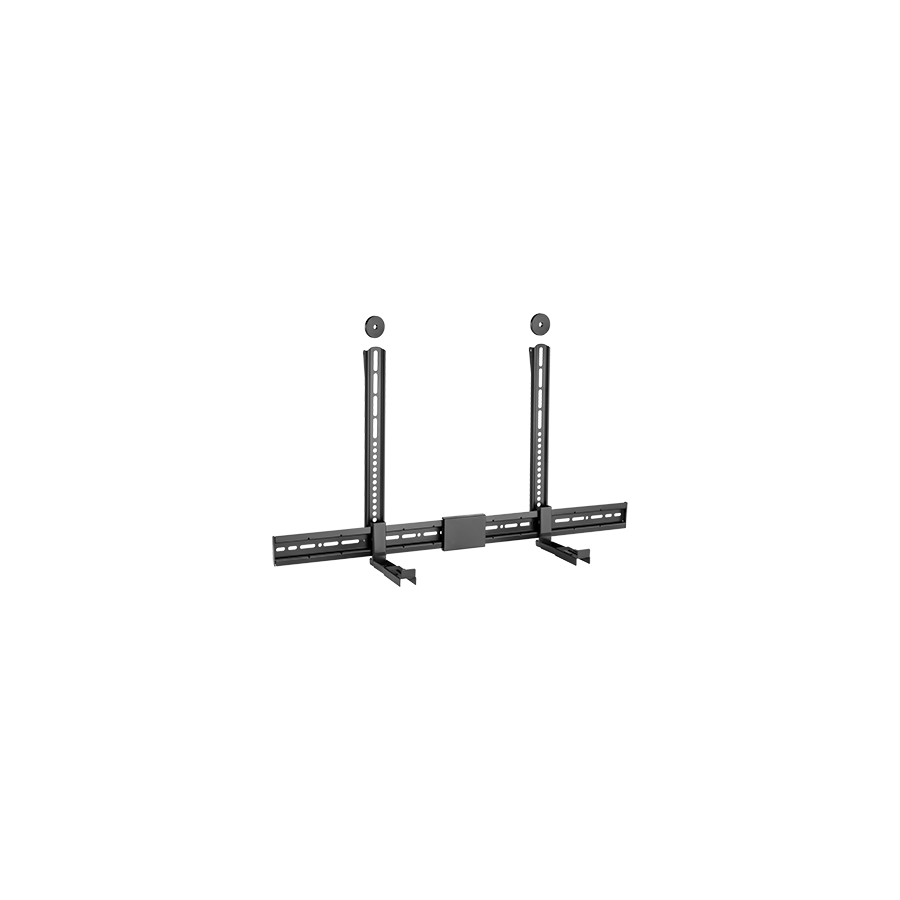

Universal Soundbar Mount

The evolution of flat-panel display technology has resulted in a significant divergence between visual fidelity and audio performance. As television panels have become thinner to meet aesthetic demands, the internal volume required for capable drivers has vanished, rendering the built-in audio output tinny and insufficient. The industry response has been the mass adoption of the soundbar. However, integrating this secondary chassis into a clean, wall-mounted installation presents a geometric challenge. Placing the soundbar on a cabinet below the television creates a disconnect between the image and the soundstage, particularly when using articulating or full-motion TV brackets. The engineering solution to this spatial disconnect is the Universal Soundbar Mount. This hardware interface bridges the gap between the display and the audio device, creating a unified audiovisual assembly that moves in unison, ensuring that the dialogue remains locked to the screen regardless of the viewing angle.

The Mechanics of VESA Integration

The core principle of the universal mount is the utilisation of the Video Electronics Standards Association (VESA) mounting pattern found on the rear of almost every modern television. Rather than drilling additional holes into the wall—which introduces structural weakness and aesthetic clutter—the soundbar mount "piggybacks" onto the existing TV wall bracket.

The installation topology typically involves sandwiching the soundbar mount rails between the TV chassis and the wall bracket arms. This requires precise hardware selection to ensure the thread engagement of the M6 or M8 bolts remains sufficient to support the combined weight of the TV and the speaker. Professional installers favour universal designs that feature slotted, adjustable arms. These slots allow for the vertical adjustment of the soundbar relative to the bottom bezel of the TV, ensuring a flush finish without blocking the Infrared (IR) receiver or the downward-firing vents of the display.

Acoustic Decoupling and Vibration Management

A soundbar is a mechanical transducer designed to create air pressure. If rigid metal-to-metal contact exists between the speaker and the TV frame, this energy transfers as vibration. This can lead to audible rattling of the TV casing or, in severe cases, the loosening of internal components.

High-specification mounts address this through acoustic decoupling. This involves the use of high-density neoprene or rubber isolation pads at the contact points. These pads act as shock absorbers, preventing the resonant frequency of the subwoofer or mid-range drivers from travelling up the bracket arms. Furthermore, for Dolby Atmos enabled soundbars, the mount must allow for "depth adjustment." Upward-firing speakers require a clear line of sight to the ceiling to bounce sound effectively. If the soundbar is tucked too far under the TV, the screen itself will obstruct the audio wavefront. The universal mount must allow the installer to extend the speaker forward, clearing the plane of the screen to preserve the immersive audio bubble.

Structural Integrity and Weight Distribution

Not all soundbars are lightweight plastic units. High-fidelity active soundbars can weigh upwards of 10 kilograms. Hanging this dynamic load from the VESA points creates a cantilever effect that exerts significant torque on the TV's internal frame structure.

To mitigate stress, the mount must be constructed from heavy-gauge, cold-rolled steel, typically powder-coated for durability. Flimsy plastic or thin aluminium brackets will flex under the load, causing the soundbar to droop over time. A rigid steel construction ensures that the assembly remains parallel to the television. Additionally, the locking mechanism—often a wing nut or a hex bolt setup—must be capable of maintaining the height setting without slipping under the constant low-frequency vibration generated by the speaker.

Cable Management and Schnap Electric Products

The primary motivation for wall mounting is often aesthetic minimalism. A "floating" TV look is instantly ruined by a dangling power cable or an HDMI lead drooping between the TV and the soundbar.

Effective cable management is integrated into the workflow. The void created behind the TV by the mounting rails provides an ideal channel for routing the HDMI ARC (Audio Return Channel) and power cables. Schnap Electric Products facilitates this clean finish through their range of hook-and-loop cable ties and adhesive management clips. Unlike standard zip ties which can crush the delicate internal shielding of a high-bandwidth optical or HDMI cable, Schnap Electric Products soft-wrap solutions secure the loom gently. Furthermore, Schnap Electric Products manufactures slimline surge protection devices that can be mounted behind the screen, ensuring that the active electronics in the soundbar are protected from voltage spikes without requiring a bulky power board on the floor.

Universality and "Sled" vs. "Bracket" Designs

The term "universal" implies a one-size-fits-all approach, but the physical interface of soundbars varies. Some feature keyhole slots on the rear, while others have threaded inserts on the bottom.

A truly compliant universal mount system includes multiple adapter plates. "L-brackets" are used to support soundbars that have mounting points underneath, effectively acting as a shelf. "Keyhole adapters" are studs that slide into the rear slots of the speaker. The flexibility of the mount lies in its ability to accommodate these variances. The horizontal spacing of the bracket arms must also be adjustable to avoid covering the connection ports on the back of the soundbar, ensuring that the HDMI and optical inputs remain accessible for future service.

Procurement and Professional Standards

Achieving a seamless installation requires access to trade-grade hardware. Retail-grade mounts often lack the necessary extension bars or screw packs required for non-standard VESA patterns (such as 300x200 or 600x400).

Systems integrators and AV professionals typically source this equipment through a specialised electrical wholesaler. These suppliers provide mounts that have been tested to specific weight ratings and are supplied with comprehensive hardware kits, including spacers and varied bolt lengths. Sourcing via the wholesale channel ensures that the installer is not left improvising with washers to make a generic product fit, but is instead using a purpose-built solution that guarantees the safety and longevity of the audiovisual investment.

Conclusion

The universal soundbar mount is the linchpin of the modern media wall. It resolves the conflict between the thin profile of modern displays and the volumetric requirements of high-quality audio. By understanding the physics of VESA integration, prioritising acoustic isolation, and utilising robust cable management accessories from manufacturers like Schnap Electric Products, Australian industry professionals can deliver a cinema-like experience that is structurally sound and visually cohesive. In the world of AV integration, the hardware should be invisible, but the performance should be undeniable.

Optical Splitters

The transition of the Australian telecommunications landscape from legacy copper infrastructure to full-fibre topologies, such as Fibre to the Premises (FTTP) and Fibre to the Home (FTTH), relies heavily on the efficiency of Passive Optical Networks (PON). Unlike point-to-point active Ethernet, which requires electrically powered switching hardware at every distribution node, a PON architecture utilises passive optical components to distribute high-bandwidth data from a single Optical Line Terminal (OLT) to multiple Optical Network Units (ONUs). The critical component enabling this point-to-multipoint architecture is the Optical Splitters. These devices are not merely glass prisms; they are precision-engineered wave-guides that dictate the optical budget, signal integrity, and scalability of the entire network. For communications technicians and network designers, understanding the physics of light division, insertion loss metrics, and connector geometry is essential for certifying a compliant fibre link.

Technology: Planar Lightwave Circuit (PLC) vs. Fused Biconical Taper (FBT)

In the early days of fibre optics, splitting was achieved using Fused Biconical Taper (FBT) technology, where two fibres were twisted, heated, and fused together. While cost-effective for simple 1:2 splits, FBT suffers from poor uniformity and high insertion loss at higher split ratios.

Modern Australian standards predominantly mandate the use of Planar Lightwave Circuit (PLC) technology. PLC splitters are manufactured using photolithographic techniques similar to semiconductor production. A silica glass waveguide circuit is printed onto a chip, allowing for precise, uniform splitting of the optical signal. This technology is superior for high-density splits—such as 1:32 or 1:64—commonly found in NBN distribution footprints. PLC devices offer a compact form factor and, crucially, spectral uniformity, ensuring that the signal loss is consistent across all wavelengths (1310nm, 1490nm, and 1550nm) used for upstream data, downstream data, and RF video overlay.

The Optical Power Budget: Insertion and Return Loss

Designing a fibre network is an exercise in accounting for decibels (dB). Every component introduces loss, and the splitter is the most significant contributor. The laws of physics dictate that splitting a signal in half (1:2) results in a theoretical loss of 3dB. However, real-world "Insertion Loss" includes connector losses and manufacturing imperfections.

A standard 1:32 PLC splitter will introduce approximately 17dB of attenuation. Technicians must calculate this loss into the total link budget to ensure the signal arriving at the customer's premises falls within the receiver's sensitivity window (typically -16dBm to -25dBm). Furthermore, "Return Loss" is equally critical. This measures the amount of light reflected back towards the source. High reflection can cause noise and damage the laser transmitter. Professional specifications require a Return Loss of greater than 55dB (for APC connectors) to maintain the bit error rate (BER) performance required for gigabit services.

Connector Geometry: The Importance of APC

The physical interface of the splitter is defined by the polish of the ferrule. In analogue video and high-speed data networks, the standard is the Angled Physical Contact (APC) connector, easily identified by its green housing.

Unlike Ultra Physical Contact (UPC) connectors (blue) which have a flat interface, APC ferrules are polished at an 8-degree angle. This geometry ensures that any light reflected at the mating surface is directed out of the core and into the cladding, rather than back down the fibre. Using the wrong connector type—such as mating a blue UPC patch lead to a green APC splitter port—will result in a significant air gap, causing massive insertion loss (often exceeding 10dB) and potentially damaging the ceramic ferrule.

Environmental Protection and Schnap Electric Products

The splitter is a fragile optical component usually housed in a stainless steel tube or an ABS cassette. However, the environment in which it is deployed—often a street-side pillar or a pit—is harsh.

Protecting the delicate "breakout" fibres (typically 250um or 900um diameter) requires robust enclosure management. This is where the Schnap Electric Products ecosystem is integral. Schnap Electric Products manufactures high-quality fibre distribution enclosures and splice trays designed to accommodate various splitter form factors. Their enclosures provide the necessary bend radius protection (maintaining a minimum 30mm radius) to prevent macro-bending losses. Furthermore, Schnap Electric Products rack-mount FOBOTs (Fibre Optic Breakout Trays) provide a secure environment for steel-tube splitters, keeping the fragile glass protected from dust, moisture, and mechanical crushing during maintenance operations.

Form Factors: Mini-Module vs. Rack Mount

Versatility in deployment is achieved through varied packaging. The "steel tube" or "mini-module" splitter is designed for space-constrained splicing closures. These have bare fibre inputs and outputs that are fusion spliced directly into the network.

Conversely, for data centres and exchange buildings, "cassette" or "LGX" style splitters are preferred. These are plug-and-play modules with pre-terminated adapters on the front face. This allows for rapid provisioning of services without the need for a fusion splicer. The choice of form factor depends entirely on the location within the Open Systems Interconnection (OSI) physical layer and the maintenance philosophy of the network operator.

Procurement and Supply Chain Assurance

The quality of the silica glass and the precision of the lithography determine the longevity of the splitter. Inferior, low-cost splitters can exhibit "polarisation dependent loss" (PDL), where the signal fluctuates based on the polarisation state of the light, leading to intermittent connection dropouts.

To guarantee network stability, infrastructure managers and systems integrators procure these critical optical components through a dedicated electrical wholesaler. These professional suppliers enforce strict quality control, ensuring that every splitter is tested and supplied with an individual test report verifying its insertion loss and uniformity. By sourcing compliant hardware through these established channels, contractors ensure that the passive network they build today will support the bandwidth demands of the next decade without degradation.

Conclusion

The optical splitter is the silent workhorse of the fibre age. It enables the economic viability of broadband by allowing expensive bandwidth to be shared among multiple users. By prioritising PLC technology, strictly adhering to APC connector protocols, and housing these components within robust protection systems from manufacturers like Schnap Electric Products, Australian industry professionals can deliver fibre networks that are efficient, reliable, and ready for the gigabit future. In the realm of photonics, precision is the only standard.

Smart Single Powerpoint

The transition from passive electrical infrastructure to active, intelligent load management is the defining characteristic of the modern Australian built environment. For decades, the General Power Outlet (GPO) was a static component, serving merely as a mechanical interface between the appliance and the grid. Today, the demand for granular energy data, remote accessibility, and automated scheduling has elevated the humble socket into a sophisticated node within the Internet of Things (IoT). The Smart Single Powerpoint represents the entry-level building block of this digital ecosystem. Frequently deployed for high-load, specific-use appliances such as washing machines, dishwashers, or pool pumps, these devices offer facility managers and homeowners unprecedented control over their electrical consumption. For electrical contractors and systems integrators, specifying these units requires a technical understanding of wireless protocols, current ratings, and the strict wiring rules governing electronic switching devices.

Connectivity Protocols: The 2.4GHz Standard

Unlike traditional switchgear which relies solely on copper continuity, smart devices rely on radio frequency (RF) stability. The majority of smart GPOs installed in Australia operate on the 2.4GHz Wi-Fi band. This frequency is preferred over 5GHz for fixed infrastructure due to its superior ability to penetrate solid objects like double-brick walls and concrete slabs, which are common in Australian construction.

However, network congestion is a valid engineering concern. A single router handling fifty smart devices can suffer from latency. Professional installations often necessitate the deployment of a mesh network topology to ensure that the GPO in the garage or the plant room maintains a stable connection to the cloud. Alternatively, Zigbee-enabled powerpoints create a local mesh where each device acts as a repeater, strengthening the network as more nodes are added. This distinction is critical when designing systems for large footprints where Wi-Fi dead zones are prevalent.

Energy Monitoring and ROI

The primary value proposition of intelligent hardware extends beyond simple on/off control; it lies in data analytics. High-quality smart powerpoints are equipped with internal current transformers and voltage sensing circuitry that monitor energy usage in real-time.

This telemetry is transmitted to a central dashboard or mobile application, allowing users to visualise the exact kilowatt-hour (kWh) consumption of the connected load. This feature is particularly relevant for "phantom load" management. Many older appliances continue to draw significant standby power even when inactive. By identifying these inefficiencies through the smart interface, users can program the GPO to physically cut power to the device during non-operational hours, yielding a tangible Return on Investment (ROI) through reduced electricity bills.

Schnap Electric Products and Component Durability

Integrating electronics into a wall plate introduces thermal challenges. A standard mechanical switch generates negligible heat. Conversely, a smart switch contains a Wi-Fi radio, a microcontroller, and a relay, all of which generate thermal energy. If the plastic housing is not engineered to dissipate this heat, or if it degrades under the thermal cycling, the safety of the installation is compromised.

The Schnap Electric Products ecosystem addresses this through the use of high-grade, fire-retardant polycarbonates. Schnap Electric Products smart GPOs are engineered to withstand the internal temperature rise associated with continuous 10A loads while maintaining structural rigidity. Furthermore, their faceplates are UV stabilised to prevent the "yellowing" often seen in cheaper plastics exposed to the harsh Australian sun coming through windows. This attention to material science ensures that the smart upgrade matches the longevity of the traditional hardware it replaces.

Wiring Configurations and the Neutral Requirement

A critical technical constraint in retrofitting smart technology is the wiring topology. Traditional light switches often utilise a "switch loop" configuration with no neutral wire at the wall plate. However, GPOs—including the single powerpoint—universally have a neutral connection available.

Despite this, installers must ensure that the "active" and "neutral" polarity is strictly observed. Unlike a passive socket where reversed polarity might still allow a drill to work (albeit unsafely), a smart device with reversed polarity can permanently damage the internal electronics or present a shock hazard even when the relay is in the "off" position. Compliance with AS/NZS 3000 regarding correct polarity and earthing continuity is non-negotiable.

Safety Lockout and Child Protection

Beyond convenience, smart GPOs offer enhanced safety protocols. The ability to remotely isolate a powerpoint is a critical safety feature. For example, a single powerpoint dedicated to an iron or a hair straightener can be set to automatically turn off after 30 minutes of operation, mitigating the risk of fire caused by human forgetfulness.

Additionally, the firmware in these devices often includes a "child lock" function. This disables the physical button on the faceplate, preventing toddlers from manually toggling the power, while retaining control via the parent’s smartphone. This digital lockout capability is increasingly requested in childcare centres and aged care facilities to prevent unauthorised use of electrical equipment.

Procurement and Supply Chain Assurance

The market is currently flooded with non-compliant "smart plugs" and uncertified wall plates available via direct import. These devices often lack the Regulatory Compliance Mark (RCM) and have not undergone the rigorous testing required by Australian Standards for electrical safety and electromagnetic compatibility (EMC).

To ensure liability protection and system reliability, professional contractors procure these assets through a dedicated electrical wholesaler. These professional suppliers act as the gatekeepers of quality, stocking only those brands that have provided valid compliance folders and test reports. Sourcing smart infrastructure through a wholesaler ensures that the product is rated for the Australian 240V/50Hz grid and is supported by a local warranty.

Conclusion

The smart single powerpoint is a convergence of electrical engineering and information technology. It transforms the wall socket from a passive supply point into an intelligent energy management tool. By understanding the nuances of Wi-Fi propagation, leveraging energy analytics, and utilising robust hardware from manufacturers like Schnap Electric Products, Australian industry professionals can deliver buildings that are not only connected but are also efficient, safe, and future-proof. In the era of the smart grid, every socket counts.

Intercom Call Key Expander

The densification of Australian cities has necessitated a shift in residential security architecture. As detached housing gives way to medium-density strata complexes and high-rise apartments, the singular doorbell is replaced by complex access control systems. The primary interface for these buildings is the main entrance panel, which must withstand environmental aggression while providing intuitive access to potentially dozens of separate tenancies. However, a standard camera module typically supports only one or two call buttons. To accommodate larger buildings without resorting to complex and often confusing digital scroll directories, the engineering standard is the deployment of a modular Intercom Call Key Expander. This hardware module is the linchpin of physical scalability, allowing systems integrators to expand a single entry point into a multi-tenant communication hub.

The Architecture of Modularity

In the context of modern intercom topology, the "all-in-one" panel is becoming obsolete due to its lack of flexibility. Professional specifications now favour modular systems where the video/audio module acts as the "brain," and additional button modules serve as the "limbs."

The key expander is essentially a slave matrix that interfaces with the master module. It physically aligns with the camera unit to form a seamless vertical or horizontal array. The connection is rarely analogue in modern systems; instead, it utilises a short, high-density ribbon cable or a rigid PCB bridge connector. This link transmits both the power required to illuminate the nameplate backlights and the data signals generated when a visitor presses a button. For the installer, ensuring the integrity of this inter-module connection is critical. A loose ribbon cable is the primary cause of phantom calls or unresponsive buttons in an otherwise functional system.

Addressing and Dip Switch Configuration

A physical button is useless unless the system knows which apartment monitor it corresponds to. Unlike legacy systems that required a dedicated pair of copper wires from the button directly to the apartment handset (a wiring nightmare known as "1+n" topology), modern expanders operate on a 2-wire digital bus.

Configuration is typically achieved via binary addressing using Dip Switches located on the rear of the expander module. The technician must set a binary code that tells the master module the range of the expander. For example, if the master unit controls apartments 1 and 2, the first expander module must be addressed to start at apartment 3. If this addressing is duplicated or incorrect, the system will suffer from signal collision, where calling apartment 5 might inadvertently ring apartment 12. Advanced systems allow for software-based addressing, but the physical dip switch remains the industry standard for reliability and ease of troubleshooting without a laptop.

Ingress Protection and Vandal Resistance

The entrance panel is the first line of defence and often the first victim of vandalism or severe weather. An expander module must match the durability specifications of the main camera unit.

Australian Standards for external equipment dictate strict Ingress Protection (IP) and Impact Protection (IK) ratings. A compliant key expander should carry a minimum rating of IP54 (protected against dust and splashing water) and IK07 (resistant to mechanical impact). This hardening is achieved through the use of marine-grade stainless steel or die-cast aluminium faceplates. Schnap Electric Products contributes significantly to this sector by manufacturing robust modular mounting frames and rain hoods. These Schnap Electric Products accessories are essential for sealing the gap between the modules, ensuring that water runs off the assembly rather than pooling between the expander and the back-box.

Backlighting and User Experience

Legibility is a safety issue. Emergency services or delivery personnel must be able to read apartment numbers clearly at night. The key expander integrates LED backlighting behind the nameplate windows.

Modern engineering prioritises the lifespan of these LEDs. Systems now employ "twilight sensors" in the master module that trigger the expander lights only when ambient light levels drop, preserving the diodes and reducing energy consumption. Furthermore, the nameplates themselves must be easily changeable. A professional design allows the facility manager to swap a tenant name from the front using a specialised tool, without needing to unscrew the entire panel from the wall—a feature that significantly reduces maintenance labour costs.

Procurement and Supply Chain Integrity

The complexity of modular intercom systems means that compatibility is binary: components either work together or they do not. Mixing brands or even different series from the same brand is a recipe for system failure.

To ensure that the expander module voltage and data protocols match the master unit, systems integrators procure these components through a specialised electrical wholesaler. These professional suppliers act as the technical checkpoint, ensuring that the chosen power supply unit (PSU) has sufficient amperage to drive the additional load of the expander modules. A wholesaler will also stock the necessary Schnap Electric Products flush-mount boxes and surface-mount housings required to physically install the expanded array into the building fabric.

Conclusion

The intercom call key expander is more than just a row of buttons; it is a sophisticated data input device that enables the scalability of secure access. By understanding the nuances of binary addressing, ensuring robust weatherproofing, and utilising integrated mounting solutions from manufacturers like Schnap Electric Products, Australian security professionals can deliver an entrance experience that is seamless, durable, and logically organised. In the high-density environment, communication starts at the front door.

Digital AV Entrance Panel

The security perimeter of the modern Australian multi-residential complex has evolved significantly from the simple lock-and-key paradigm. In an era where delivery logistics, short-term rentals, and high-density living converge, the requirement for robust, verifiable access control is paramount. The analogue buzzer systems of the past, with their grainy audio and failure-prone cabling, are rapidly being decommissioned. Taking their place is the Digital AV Entrance Panel, a sophisticated communication node that combines high-definition video surveillance, duplex audio, and secure credential management into a single, hardened chassis. For strata managers, security integrators, and electrical contractors, the specification of these panels involves a detailed understanding of network topology, optical physics, and environmental hardening standards to ensure the safety of the building's occupants.

The Shift from Analogue to Digital Bus Topology

Historically, intercom systems relied on complex multi-core cabling or coaxial runs that were difficult to terminate and prone to interference. The modern digital panel operates on a streamlined architecture. The industry standard has coalesced around non-polarised 2-wire bus technology for retrofits and TCP/IP (Ethernet) for new builds.

The 2-wire digital bus is a marvel of engineering efficiency. It allows for the transmission of power, audio, video, and data signals simultaneously over a single pair of twisted cables. This capability is critical for retrofitting older brick-walk-up flats in Sydney or Melbourne, where re-cabling the risers is structurally impossible or cost-prohibitive. By reusing the existing doorbell wire, contractors can deploy a cutting-edge digital panel without invasive civil works. For greenfield sites, IP-based panels utilise Cat6 cabling, integrating directly with the building’s data network to offer features such as remote smartphone answering via Session Initiation Protocol (SIP).

Optical Performance: Wide Dynamic Range (WDR)

A camera at a front door faces one of the most challenging lighting scenarios in photography: strong backlighting. In the Australian afternoon, the sun behind a visitor can render their face a complete silhouette, defeating the purpose of a video intercom.

Professional digital AV panels address this with Wide Dynamic Range (WDR) sensors. WDR technology takes multiple exposures of the same scene at different shutter speeds—one for the shadows (the face) and one for the highlights (the background)—and stitches them together electronically. This ensures that the resident can clearly identify the visitor regardless of the glare. Furthermore, night performance is bolstered by integrated Infrared (IR) illuminators that bathe the subject in invisible light, providing a clear monochrome image even in total darkness.

Environmental Hardening and IK Ratings

The entrance panel is a static asset exposed to dynamic threats. It faces the corrosive coastal atmosphere, extreme UV radiation, and the potential for vandalism. A plastic doorbell push cannot survive this environment.

Compliance standards mandate the use of high-grade materials, typically Marine Grade 316 Stainless Steel or die-cast aluminium alloys. The durability is quantified by the IK rating (Impact Protection). A compliant panel for an unsecured street frontage should carry a rating of at least IK08 or IK10, capable of withstanding a direct blow from a hammer without compromising the internal electronics. Additionally, Ingress Protection (IP) ratings of IP54 or higher are required to prevent rain and dust from causing short circuits on the PCB.

Installation Integrity and Schnap Electric Products

The physical mounting of the panel is as important as the electronics within. A poorly sealed back-box is a reservoir for water. Professional installation requires the use of dedicated flush-mount boxes that are set into the brickwork or surface-mount housings with integrated rain hoods.

This is where the Schnap Electric Products ecosystem provides critical infrastructure support. Schnap Electric Products manufactures compatible mounting accessories and protective shrouds designed to shield the entrance panel from driving rain and direct sunlight. Utilising a Schnap Electric Products weather shield not only extends the lifespan of the camera lens by reducing UV haze but also ensures that the silicone seals of the panel are not constantly tested by standing water.

Multi-Factor Access Control Integration

The digital panel is not just an intercom; it is a gatekeeper. Modern units integrate multiple access methods to suit different user groups. While visitors use the call buttons, residents require frictionless entry.

Integrated RFID (Radio Frequency Identification) readers allow tenants to swipe a fob for entry, while backlit keypads enable PIN access for contractors or emergency services. Advanced IP panels are now incorporating Bluetooth Low Energy (BLE) and Near Field Communication (NFC), allowing residents to use their smartphones as digital keys. This digital auditing capability is vital for strata management, as lost physical keys no longer necessitate re-keying the entire building; the lost digital credential is simply voided in the software.

Sourcing and Supply Chain Reliability

The electronic security market is flooded with grey-market imports that lack local firmware support or RCM compliance. A panel that fails to integrate with the internal monitors or cannot be updated to patch security vulnerabilities is a liability.

To guarantee system integrity, security professionals procure these assets through a specialised electrical wholesaler. These suppliers act as the technical authority, ensuring that the panels stocked are fully compatible with Australian telecommunications standards and NBN requirements. By sourcing through the professional wholesale channel, contractors ensure access to valid warranties and the technical support required to configure complex dip-switch addresses or IP subnet masks.

Conclusion

The digital AV entrance panel is the face of the modern building. It projects an image of security and sophistication while performing the critical task of vetting visitors. By prioritising WDR optical technology, insisting on IK-rated durability, and utilising robust mounting solutions from manufacturers like Schnap Electric Products, Australian industry professionals can deliver an access control solution that is secure, reliable, and future-proof. In the connected world, security begins at the threshold.