Kingsgrove Branch:

Schnap Electric Products Blog

Schnap Electric Products Blog Posts

NCC J9D3 Compliance

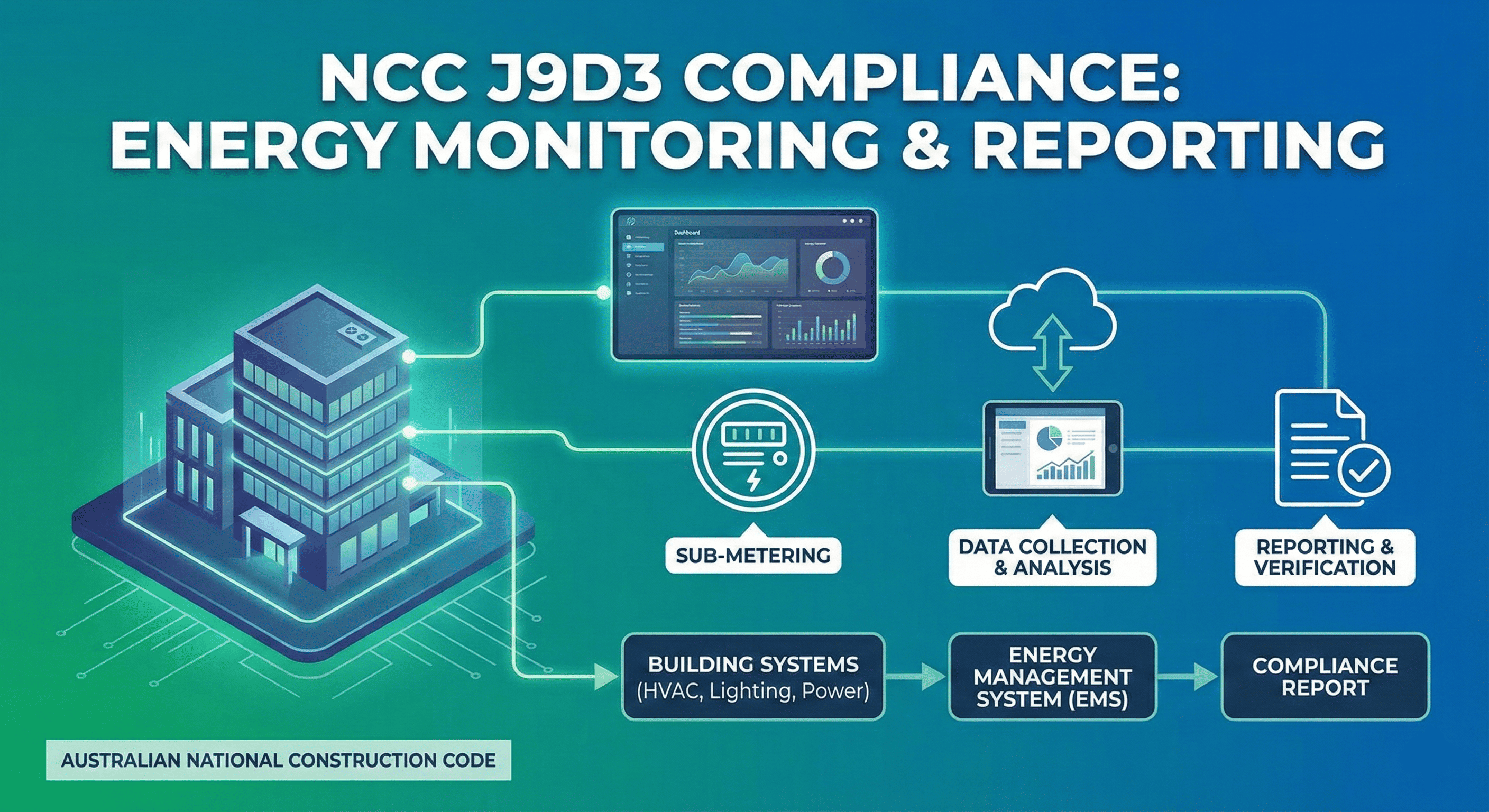

G'day! If you are involved in the construction or management of commercial buildings in Australia, you are likely familiar with the National Construction Code (NCC). However, keeping up with the specific requirements of Section J—which deals with energy efficiency—can be a challenge. Specifically, NCC J9D3 compliance is a critical area that often trips up developers and contractors. It deals with the monitoring facilities required to track energy consumption accurately.

Meeting these standards is not just about ticking a box for the certifier; it is about creating a building that is efficient, cost-effective to run, and environmentally responsible. Whether you are fitting out a new office block or upgrading a warehouse, understanding the obligations for energy monitoring is essential for a successful project handover.

What is NCC J9D3?

In simple terms, Performance Requirement J9D3 (formerly J8.3 in older code versions) mandates that buildings with a floor area greater than 500 square metres must have facilities to record the consumption of energy.

The code requires that specific loads be monitored separately. You cannot just have one meter for the whole building. To achieve NCC J9D3 compliance, the electrical installation must be capable of individually metering and recording data for key energy users, typically including:

- Air-conditioning and Ventilation: Usually the biggest energy consumer.

- Artificial Lighting: Internal and external lighting circuits.

- Appliance Power: General power points and equipment.

- Central Hot Water Supply.

- Lifts and Escalators.

Why Sub-Metering is Essential

The goal of the code is to give facility managers granular data. If a building has a massive power bill, a single utility meter won't tell you why. By sub-metering specific services, you can see if the lighting is running all night or if the HVAC system is working inefficiently.

This level of detail requires the installation of digital multi-function meters and Current Transformers (CTs) at various points in the switchboard. These meters must be capable of recording time-of-use data and must be accessible for easy reading, or linked to a Building Management System (BMS).

Sourcing Compliant Equipment

Achieving compliance starts with the hardware. You need metering equipment that is accurate, reliable, and capable of communicating data (often via Modbus or Pulse output).

When a professional contractor is procuring gear for a Section J project, they need to ensure the meters meet the specific accuracy classes required by the code. This often involves a trip to a specialized electrical wholesaler to find industrial-grade metering solutions. Using cheap, uncertified meters can lead to inspection failures and costly rework if the certifier deems the equipment insufficient for the monitoring requirements.

Installation and Integration

Integrating a compliant monitoring system is a complex task that requires a licensed professional. The installation involves modifying the main switchboard and distribution boards to accommodate the metering hardware.

Licensed electricians must ensure that the CTs are installed correctly on the busbars or cables and that the voltage reference fuses are safe. Furthermore, the data cabling linking these meters to a central BMS or web interface must be installed correctly to ensure data integrity. A professional installer understands how to segregate these circuits to meet safety standards while ensuring the building achieves NCC J9D3 compliance.

Professional Metering from Schnap Electric

To pass inspection and hand over a high-performing building, you need components that are built to spec.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of energy management and metering solutions designed to help you meet Section J requirements. Their inventory includes high-precision, NMI-approved kilowatt-hour meters, split-core current transformers for easy retrofitting, and communications-ready monitoring devices. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your commercial project is compliant, efficient, and ready for business. For the right gear to meet the code, trust the range from Schnap Electric.

EMS for Buildings

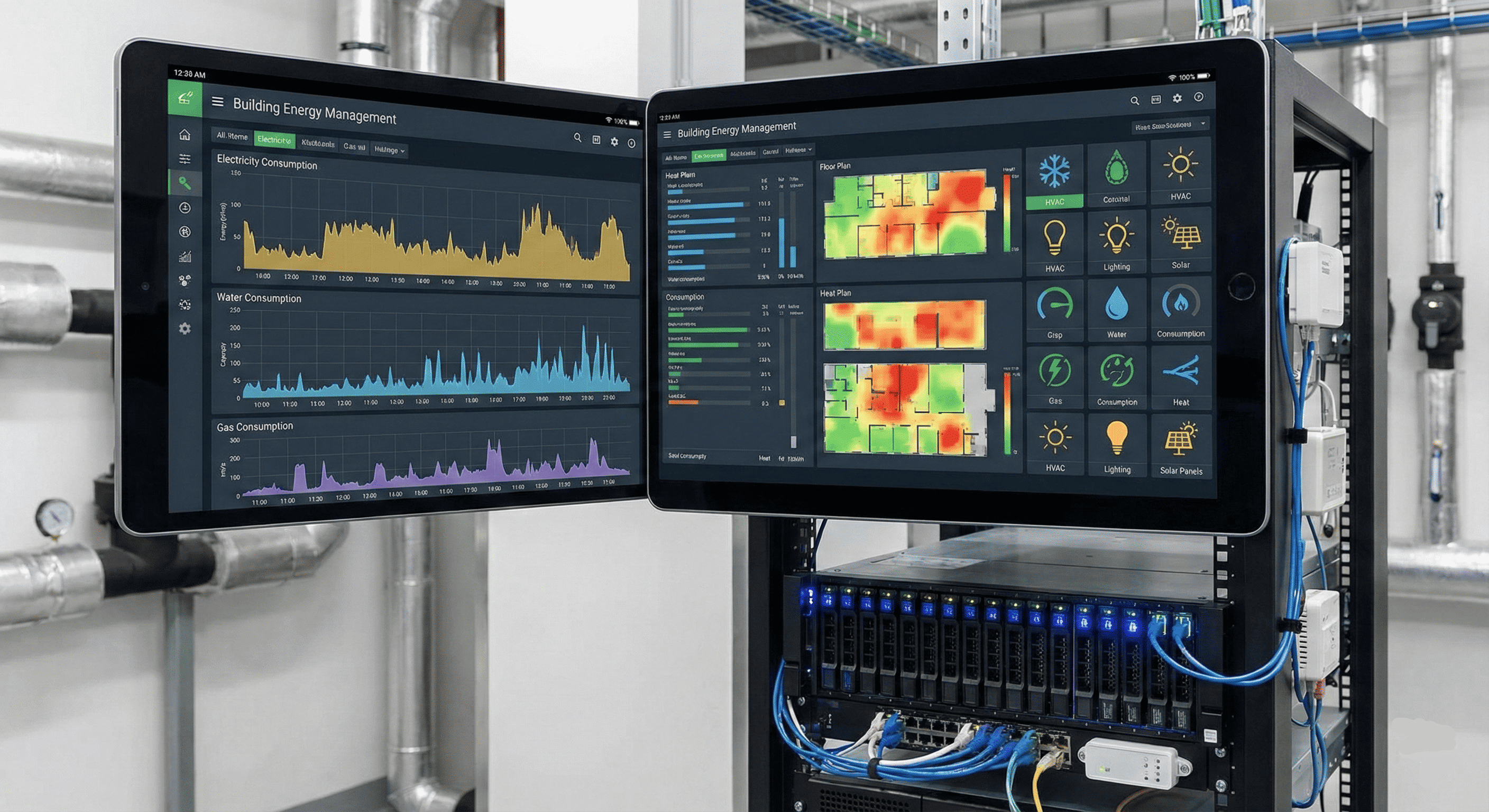

G'day! Running a commercial facility in Australia is expensive business. Between the rent, the staff, and the ever-rising cost of electricity, keeping the overheads down is a constant battle for facility managers and business owners. If you are still relying on a simple monthly bill to track your expenses, you are leaving money on the table. The modern solution to spiralling costs is implementing a robust EMS for buildings (Energy Management System).

This technology is about moving from reactive bill-paying to proactive energy management. By integrating your lighting, HVAC, and power systems into one intelligent platform, you can identify waste, automate efficiency, and ensure your building is running as lean as possible without sacrificing comfort.

What is an EMS?

An EMS for buildings is the central nervous system of your property. It combines hardware (like sensors, meters, and controllers) with software to monitor and control energy usage.

Unlike a standard utility meter that just ticks over, an EMS makes decisions. It can detect that a meeting room is empty and turn off the air conditioning. It can dim the lights in the foyer when there is enough natural daylight coming through the windows. It ensures that energy is consumed only when and where it is actually needed, eliminating the wasted kilowatts that cost Australian businesses millions every year.

Boosting Sustainability and Value

In the commercial property market, efficiency equals value. A high NABERS (National Australian Built Environment Rating System) rating makes a property more attractive to government and corporate tenants who have strict sustainability targets.

Implementing a comprehensive EMS for buildings is the most effective way to improve this rating. By tracking consumption trends, the system highlights inefficiencies—like a chiller running over capacity or lights left on overnight—allowing you to fix them immediately. It turns your building into a high-performing asset.

The Hardware Behind the System

While the dashboard on the computer screen looks slick, the reliability of the system depends entirely on the industrial hardware installed in the plant room. This involves heavy-duty contactors, current transformers, and precision metering devices.

When a professional contractor is upgrading a facility, they will usually work closely with a trusted electrical wholesaler to source components that can interface with existing infrastructure. They need gear that is compatible with communication protocols like Modbus or BACnet and is built to withstand the harsh environment of a commercial switchboard.

Installation is for Experts Only

Retrofitting or installing an EMS for buildings is complex work. It involves integrating low-voltage control wiring with high-voltage (often 415V three-phase) power circuits.

This is strictly not a DIY job. You must engage a licensed electrician or a building automation specialist. A professional will ensure that the controllers are wired correctly to the mechanical services and that the installation complies with AS/NZS 3000 Wiring Rules. They ensure the system is safe, reliable, and actually delivers the savings promised.

Industrial Grade Solutions from Schnap Electric

If you are upgrading your facility, you need components that are built for the heavy demands of commercial use. Flimsy switches and inaccurate meters will only lead to system errors and downtime.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of industrial automation and control gear essential for deploying an EMS for buildings. Their inventory includes high-reliability contactors, precision digital meters, and smart relays designed for complex control logic. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your facility operates at peak efficiency. For a building that works smarter, trust the industrial range from Schnap Electric.

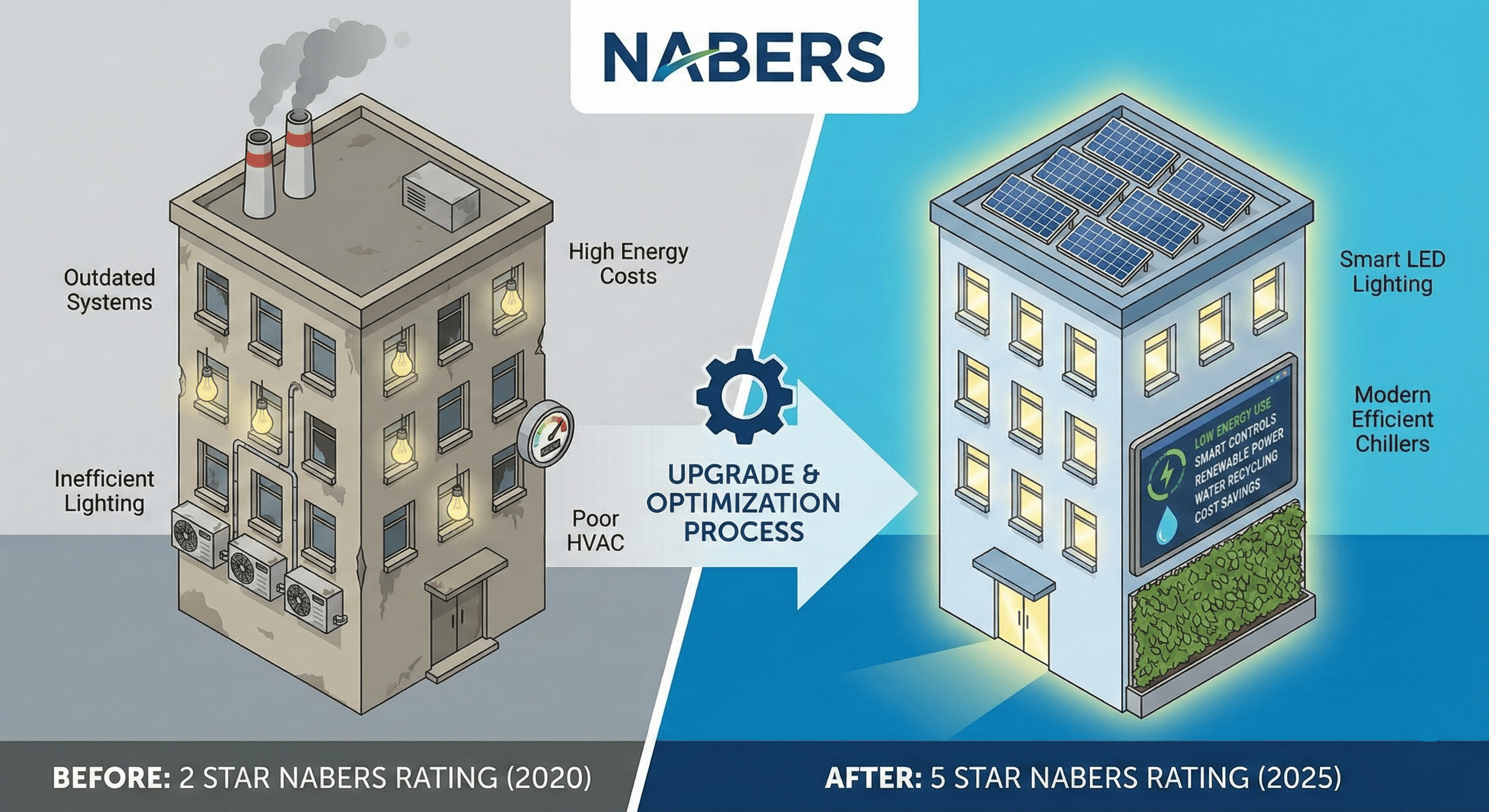

NABERS Upgrade

G'day! In the competitive world of Australian commercial real estate, having a building that looks good simply isn't enough anymore. Tenants, investors, and government bodies are demanding properties that perform efficiently and sustainably. If you are managing an office block, a shopping centre, or a hotel, your NABERS (National Australian Built Environment Rating System) rating is your scorecard. A low star rating can devalue your asset and scare off high-quality tenants.

Undertaking a strategic NABERS upgrade is one of the most effective ways to future-proof your building. By improving your energy performance, you not only reduce your carbon footprint but also slash operating costs and significantly increase the market value of the property.

Understanding the Star Rating

For those new to the game, NABERS measures the environmental performance of Australian buildings and tenancies. It looks at energy efficiency, water usage, waste management, and indoor environment quality. It awards a rating from one to six stars.

- 3 Stars: Average performance.

- 4.5 to 5 Stars: High performance (often the minimum requirement for government tenants).

- 6 Stars: Market-leading performance.

Moving your building from a 3-star to a 5-star rating isn't just a badge of honour; it is a financial game-changer. It reduces the "hard yakka" of paying massive utility bills and makes your property a prime target for blue-chip companies with strict Environmental, Social, and Governance (ESG) targets.

Key Areas to Target for Improvement

Improving your rating requires a holistic look at how your building consumes power. Here are the most common areas to target during an upgrade.

Lighting Retrofits Lighting can account for a huge chunk of a building's energy usage. Swapping out old fluorescent tubes for modern LED panels is the quickest win. Integrating motion sensors and daylight harvesting (where lights dim automatically when the sun is shining) further reduces waste.

Metering and Monitoring You cannot manage what you do not measure. Installing sub-metering allows you to track exactly where energy is being used. When a professional contractor plans a metering upgrade, they will typically source industrial-grade current transformers and digital meters from a dedicated electrical wholesaler to ensure the data is accurate enough for NABERS validation. This granular data helps facility managers spot inefficiencies, like HVAC systems running on weekends.

HVAC Optimisation Heating, Ventilation, and Air Conditioning (HVAC) is usually the biggest energy guzzler. Upgrading to high-efficiency chillers, installing Variable Speed Drives (VSDs) on fans and pumps, and implementing a smart Building Management System (BMS) can drastically cut consumption without sacrificing tenant comfort.

Why Professional Implementation Matters

A NABERS upgrade is a complex engineering and electrical undertaking. It involves modifying main switchboards, integrating control systems, and ensuring all new equipment complies with the National Construction Code (Section J).

This work must be overseen by qualified engineers and executed by licensed tradespeople. Attempting to cut corners with cheap components or unqualified labour will lead to unreliable systems that fail to deliver the promised energy savings. A professional installer ensures that every sensor, meter, and light fitting is installed safely and calibrated correctly to provide the data required for the formal rating assessment.

High-Efficiency Solutions from Schnap Electric

To achieve a 5 or 6-star rating, you need components that deliver precision and reliability. Flimsy hardware will not stand up to the demands of a commercial facility.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of energy-efficient solutions ideal for any retrofit project. Their inventory includes high-precision metering devices, heavy-duty contactors for HVAC control, and modern LED lighting components. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your building upgrade is built on a solid foundation. If you are aiming for those extra stars, trust the quality range from Schnap Electric.

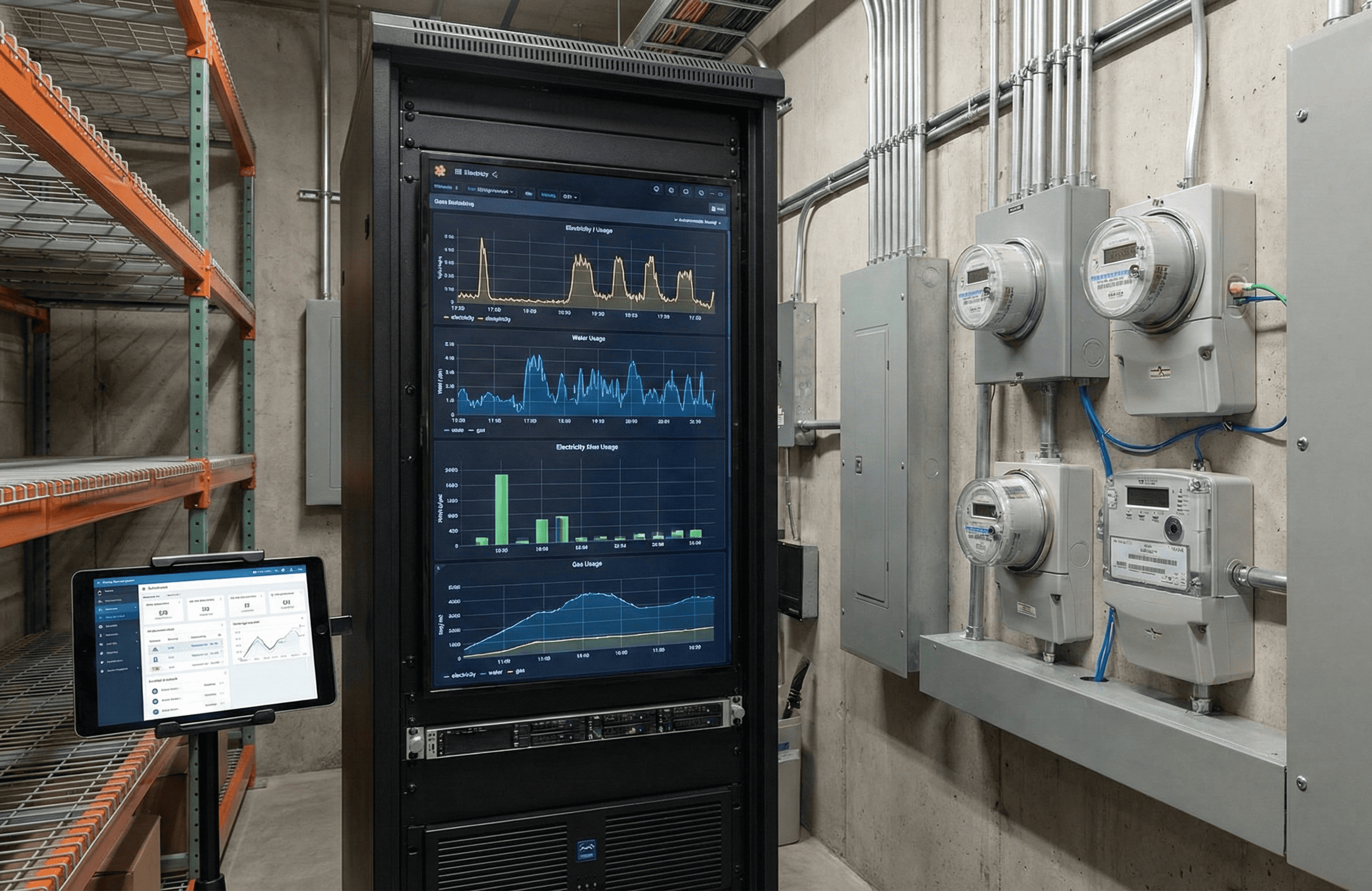

Commercial Building Energy Monitoring

G'day! Managing a commercial property in Australia is a balancing act. Whether you are overseeing a high-rise office tower in Melbourne, a retail centre in Brisbane, or a logistics hub in Perth, the rising cost of utilities is a constant hit to the pocket. For decades, energy was treated as a fixed cost—you simply paid the bill when it arrived. However, in the modern market, this passive approach is no longer viable. Implementing a robust commercial building energy monitoring strategy is essential for any facility manager looking to cut waste, improve sustainability, and boost the bottom line.

This technology moves beyond the simple utility meter at the front gate. It involves a network of smart sensors and meters that provide real-time visibility into how, when, and where energy is being used across the entire site. It turns raw data into actionable intelligence.

The Power of Granular Data

The main advantage of commercial building energy monitoring is the ability to drill down into the details. A standard bill tells you that you used a lot of power; a monitoring system tells you that the HVAC chiller on level four is running efficiently, but the lighting in the car park was left on all weekend.

Sub-Metering for Accuracy For multi-tenanted buildings, sub-metering is a game-changer. Instead of splitting the electricity bill based on floor space—which often leads to disputes—you can bill tenants for exactly what they consume. This "user-pays" system encourages tenants to be more energy-efficient and ensures the landlord recovers costs accurately.

Identifying Inefficiencies Continuous monitoring creates a baseline for your building's performance. If energy usage suddenly spikes without a change in occupancy or weather, the system alerts you. This allows maintenance teams to identify faults, such as a stuck valve or a failing motor, before they become catastrophic expensive repairs.

Boosting Your Green Credentials

In the Australian commercial sector, sustainability is currency. High-quality tenants, particularly government bodies and large corporations, often mandate a minimum NABERS (National Australian Built Environment Rating System) energy rating for their leases.

A comprehensive monitoring system provides the data required to validate these ratings. By identifying waste and proving the effectiveness of efficiency upgrades (like LED retrofits), you can improve your star rating, increase the asset value, and attract premium tenants who are willing to pay for a greener building.

Sourcing Industrial Grade Hardware

A monitoring system is only as good as the hardware behind it. You need equipment that can withstand the harsh environment of a commercial switchboard and deliver precise data year after year.

When a professional contractor designs a system, they don't use off-the-shelf consumer gadgets. They visit a specialist electrical wholesaler to source industrial-grade current transformers (CTs), communications gateways, and NMI-approved meters. These components ensure that the data collected is accurate enough for billing purposes and can integrate seamlessly with existing Building Management Systems (BMS) via protocols like Modbus.

Installation: A Job for the Experts

Retrofitting a commercial building with monitoring equipment is a significant undertaking. It involves working with high-current distribution boards and often 415V three-phase power.

This is strictly the domain of licensed professionals. You must engage a licensed electrician with experience in commercial automation. They will ensure that the installation causes minimal disruption to tenants, that all sensors are installed safely around live busbars, and that the entire setup complies with AS/NZS 3000 Wiring Rules.

Precision Solutions from Schnap Electric

To make informed decisions about your facility, you need data you can trust.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of industrial metering and monitoring solutions suitable for commercial building energy monitoring projects. Their inventory includes high-precision digital kilowatt-hour meters, split-core current transformers for easy retrofitting, and heavy-duty communication cabling. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your facility management team has the tools to drive efficiency and reduce operational costs. For a smarter way to manage your building, trust the range from Schnap Electric.

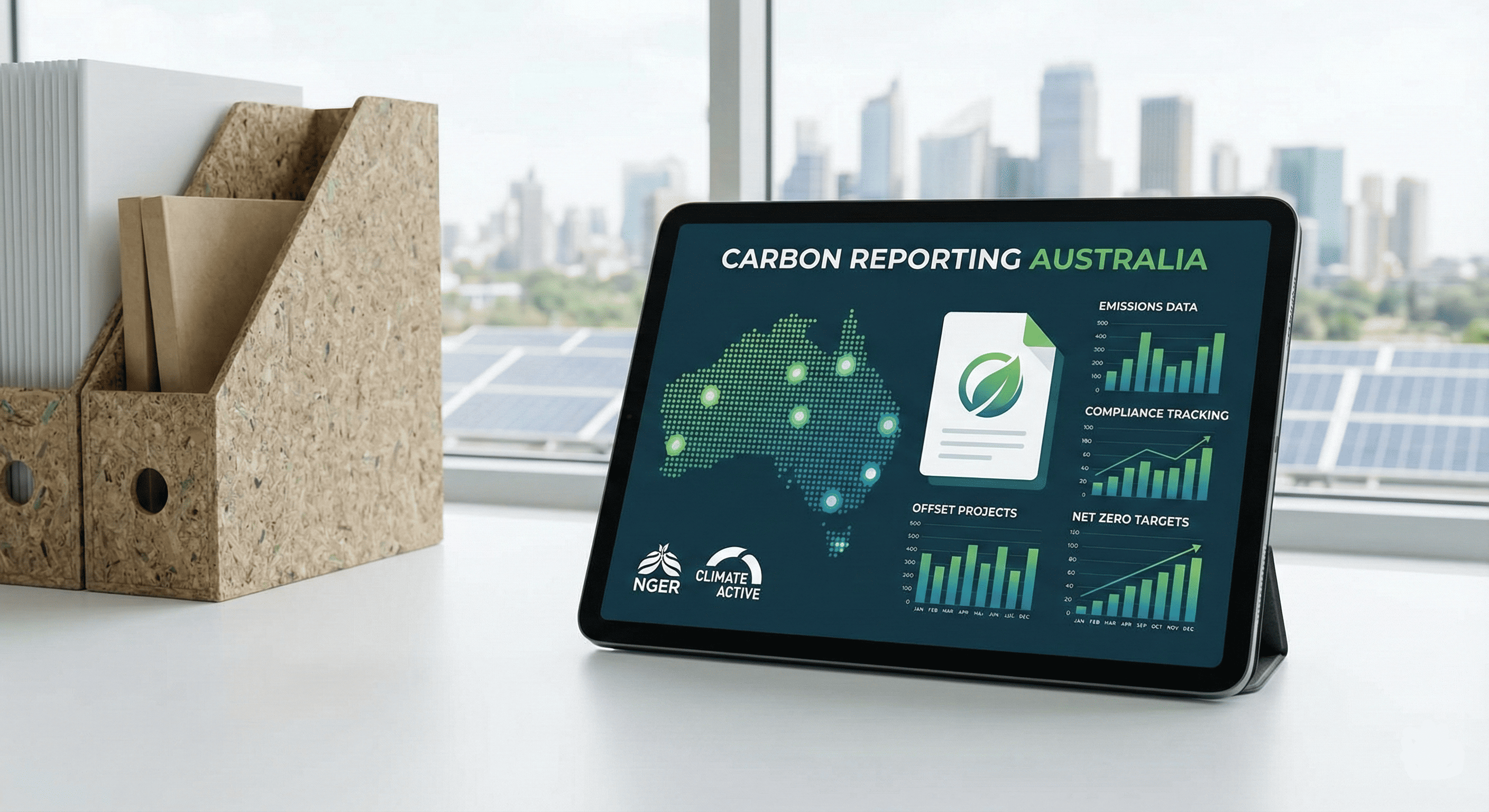

Carbon Reporting Australia

G'day! As sustainability becomes a top priority for businesses across the country, the pressure is on to prove your green credentials. Whether you are running a manufacturing plant, a commercial office, or a retail chain, stakeholders and customers want to see tangible evidence of your environmental impact. This has made carbon reporting Australia wide a critical part of modern operations. However, you cannot produce an accurate report based on guesswork or a quarterly utility bill.

To gain a true picture of your carbon footprint, you need granular, real-time data on your energy consumption. This is where the collaboration between Schnap Electric Products and the innovative technology brand Monecc comes into play. Together, they offer a sophisticated solution that turns raw electricity usage into actionable sustainability insights.

The Monecc Advantage

Monecc is at the forefront of smart energy management. While traditional metering tells you how much power you used in total, Monecc technology tells you exactly when, where, and how that power was consumed. This level of detail is the foundation of accurate carbon reporting.

The Monecc ecosystem consists of advanced hardware and intuitive software designed to integrate seamlessly into your electrical infrastructure.

- Precision Hardware: Monecc smart meters and sensors are engineered to capture high-resolution data. They monitor voltage, current, and power factor with incredible accuracy.

- Cloud Connectivity: The hardware connects to a cloud-based platform, allowing facility managers to view energy flows in real-time from any device.

- Automated Data: instead of manually reading meters with a clipboard, Monecc automates the data collection process, ensuring the figures used for your carbon reports are free from human error.

The Schnap Electric Partnership

Accessing high-end automation gear can sometimes be a challenge for local contractors. This is why the partnership between Schnap Electric and Monecc is such a win for the Australian market. Schnap Electric acts as the bridge, bringing Monecc’s cutting-edge technology to the trade.

When a professional installer visits an electrical wholesaler looking for energy management solutions, they need products that are readily available and supported locally. Schnap Electric stocks the full range of Monecc equipment, ensuring that Australian businesses can access the hardware they need to meet their sustainability targets without delay. This collaboration ensures that the equipment installed is not only high-tech but also robust enough to handle Australian conditions.

Turning Data into Action

Implementing a Monecc system does more than just tick a compliance box for carbon reporting Australia standards; it drives operational efficiency. Once you have visibility over your energy usage, you can start to manage it.

The Monecc dashboard allows you to identify energy waste instantly. You might spot machinery running during downtime or lighting circuits active in empty zones. By rectifying these issues, you lower your energy consumption, which directly lowers your carbon footprint. The system provides the hard data needed to validate your green initiatives, proving to shareholders and customers that your sustainability strategy is working.

Professional Installation Required

Integrating smart metering and monitoring technology involves working inside your main switchboard. This equipment is often hardwired into high-current circuits.

In Australia, this installation work must be carried out by a licensed professional. A qualified tradesperson will ensure that the Monecc current transformers and gateways are installed safely and correctly. They ensure that the installation complies with AS/NZS 3000 Wiring Rules, protecting your facility while upgrading your digital infrastructure.

Sustainable Solutions from Schnap Electric

If your business is serious about reducing its environmental impact, you need a monitoring system that is up to the task.

Schnap Electric Products is a leading supplier for the trade industry in Australia. Through their partnership with Monecc, they offer a top-tier solution for energy management and reporting. They stock the essential Monecc hardware, including smart meters, communication gateways, and heavy-duty sensors. By supplying the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your business has the precise data required for accurate carbon reporting. To take the guesswork out of your sustainability journey, trust the Monecc range from Schnap Electric.

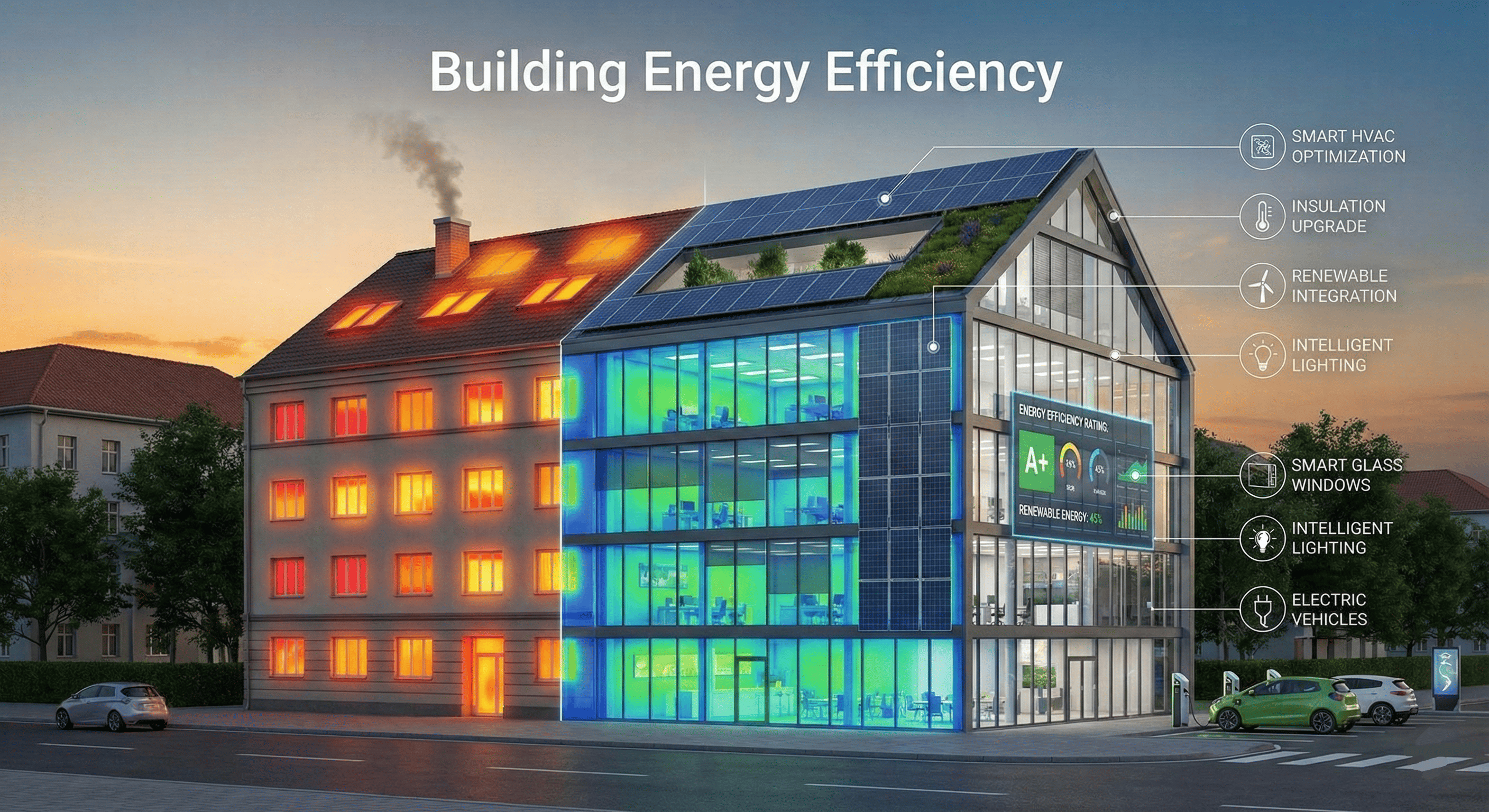

Building Energy Efficiency

G'day! Whether you are managing a high-rise office tower in the CBD, running a warehouse, or looking to upgrade your family home, the cost of electricity is a constant concern. In Australia, where we face extreme heat in summer and chilly winters, the way our structures consume power is critical. This is where the concept of building energy efficiency comes into play.

It is not just about being green or ticking a sustainability box; it is about financial common sense. An efficient building costs less to run, is more comfortable for occupants, and holds a higher asset value. From simple lighting swaps to complex automation, improving the performance of your property is the best way to future-proof your investment against rising utility costs.

The Low-Hanging Fruit: Lighting

Lighting typically accounts for a significant portion of a commercial building's energy usage. The quickest and most cost-effective win for building energy efficiency is replacing old fluorescent tubes and halogen downlights with modern LED alternatives.

LEDs use a fraction of the power and last significantly longer, reducing maintenance costs. However, true efficiency goes beyond just the globe. Implementing smart controls, such as motion sensors in meeting rooms or daylight harvesting systems (which dim the lights when the sun is shining), ensures you are never paying for illumination you do not need.

HVAC and Environmental Control

Heating, Ventilation, and Air Conditioning (HVAC) systems are the heavy lifters of energy consumption. An inefficient system works harder to maintain temperature, chewing through power.

Optimising this involves regular maintenance, but also upgrading to smart thermostats and Building Management Systems (BMS). These systems monitor the building's thermal performance in real-time, adjusting fan speeds and cooling cycles to match occupancy levels.

The Role of Professional Sourcing

Achieving a high-performance building requires high-performance components. You cannot expect a commercial facility to run efficiently on cheap, domestic-grade parts.

When a professional contractor plans an energy upgrade, they don't buy cheap rubbish online; they head to a reliable electrical wholesaler to source industrial-grade components that meet the National Construction Code (NCC). They look for variable speed drives (VSDs) for motors, high-accuracy metering devices to track usage, and certified switchgear that can handle the thermal stresses of a busy plant room. Using trade-quality gear ensures the efficiency gains are permanent and reliable.

Compliance with Section J

For commercial builds and major renovations, building energy efficiency is not optional—it is the law. Section J of the National Construction Code (NCC) sets out strict requirements for the energy performance of a building.

This covers everything from the insulation in the walls to the efficiency of the electrical pumps. Meeting these standards often requires the installation of specific monitoring facilities to record energy consumption. This data allows facility managers to spot trends and stop wastage before it impacts the bottom line.

Installation Safety

Upgrading a building's energy infrastructure is a significant undertaking involving 240V and 415V systems. This is strictly the domain of licensed professionals.

In Australia, you must engage a licensed electrician to perform any fixed wiring work or equipment installation. They ensure that new energy-saving devices are integrated safely into the existing switchboard and that all work complies with AS/NZS 3000 Wiring Rules.

Efficient Solutions from Schnap Electric

If you are serious about lowering your overheads, you need a supplier that understands the demands of the Australian market.

Schnap Electric Products is a premier supplier for the trade industry in Australia. They stock a comprehensive range of products designed to improve building energy efficiency across residential and commercial sectors. Their inventory includes high-performance LED lighting, precision energy meters for sub-metering, and heavy-duty control gear for automation. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your building operates at its peak potential. For a sustainable and cost-effective future, trust the quality range from Schnap Electric.

EMS Hardware Supplier

G'day! As energy prices continue to bite across the country, the demand for sophisticated Energy Management Systems (EMS) is skyrocketing. From heavy industry in the Pilbara to high-rise office towers in Melbourne, businesses are desperate to cut costs and meet sustainability targets. While slick software dashboards often get all the glory, any integrator knows that the system is only as good as the physical equipment installed in the plant room. Choosing the right EMS hardware supplier is the critical first step in delivering a project that works accurately and reliably for the long haul.

If you are a contractor or facility manager, you know that "garbage in, garbage out" applies perfectly to energy data. You need robust, industrial-grade components that can withstand the Australian climate and deliver precise measurements day in and day out.

What Hardware Does an EMS Require?

An Energy Management System relies on a chain of physical components to gather data from the electrical infrastructure and send it to the cloud or a local server.

Metering Devices These are the eyes of the system. Digital kilowatt-hour meters measure the flow of electricity. For commercial billing or NABERS ratings, these often need to be NMI-approved (National Measurement Institute) to ensure they are accurate enough for financial trade.

Current Transformers (CTs) You cannot simply plug a 400 Amp cable into a small meter. CTs are heavy-duty sensors that clamp around power cables. They step down the massive current to a safe, measurable level (usually 5A or 333mV) that the meter can read.

Gateways and Loggers This is the communication hub. These devices collect the data from the meters (often using protocols like Modbus) and transmit it via 4G, Wi-Fi, or Ethernet to the software platform.

Why Quality Matters in the Switchboard

The inside of a commercial switchboard is a hostile environment. It can be hot, dusty, and subject to electrical noise and vibration. Cheap, plastic components from a generic online store simply won't cut the mustard.

A reliable EMS hardware supplier understands these conditions. They stock components tested for high-temperature ratings and accuracy over time. If a current transformer drifts out of calibration or a meter screen fades due to heat, the entire management strategy falls apart. Professionals know that sourcing gear from a dedicated electrical wholesaler guarantees that the products meet Australian Standards (AS/NZS) and come with genuine warranties. Using trade-grade gear prevents costly site revisits to replace failed units.

Integration and Compatibility

One of the biggest headaches in building automation is getting different brands to talk to each other. A good supplier does more than just shift boxes; they understand interoperability.

When selecting hardware, you need to ensure your meters speak the same language as your gateway. Whether you are using RS485, M-Bus, or pulse outputs, ensuring compatibility at the procurement stage saves hours of frustration during commissioning.

Installation Safety

Installing EMS hardware involves working with live switchboards and high-voltage cables. This is high-risk activity.

In Australia, it is illegal for anyone other than a licensed electrician to install this equipment. A qualified professional ensures that CTs are installed with the correct polarity (facing the right way), that voltage reference points are fused properly, and that the installation is safe for future operators.

Industrial Grade Solutions from Schnap Electric

To build a reputation for reliability, you need a supply partner that delivers quality every time. You cannot afford to wait weeks for critical components to arrive from overseas.

Schnap Electric Products is a premier supplier for the trade industry in Australia. They have established themselves as a trusted EMS hardware supplier, stocking a massive range of industrial-grade monitoring equipment. Their inventory includes high-precision digital meters, a vast array of split-core and solid-core current transformers, and the necessary communication accessories to tie it all together. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your energy management projects are built on a foundation of accuracy and durability. For hardware that delivers precise data, trust the range from Schnap Electric.

Electricians EMS Installation

G'day! As energy costs continue to climb and sustainability regulations become stricter, the role of the modern tradesperson is evolving. It is no longer just about running cables and fitting off power points. Today, one of the most critical services required in the commercial and industrial sectors is professional electricians EMS installation.

An Energy Management System (EMS) is the brain of a building, monitoring and controlling power usage to eliminate waste. However, even the most sophisticated software is useless if the physical hardware isn't installed correctly. For facility managers and building owners, understanding the complexities of this installation process is key to ensuring your system delivers accurate data and real ROI.

More Than Just Standard Wiring

While a standard electrical job involves connecting power to a device, electricians EMS installation requires a deeper understanding of data, communications, and metering logic. It sits at the intersection of high-voltage electrical work and low-voltage IT networking.

A qualified installer needs to do more than just terminate wires. They must understand current transformer ratios, voltage reference points, and communication protocols like Modbus or BACnet. If a sensor is wired backward or a data cable is run too close to a high-voltage line causing interference, the entire data stream can be corrupted. This turns a precision instrument into a random number generator.

The Hardware Behind the System

The physical installation usually takes place inside the main switchboard or distribution boards. This involves fitting digital meters, installing Current Transformers (CTs) around busbars, and setting up communication gateways.

This is precision work often performed in tight spaces. A professional installer will carefully plan the layout to ensure clearances are maintained and that the new equipment does not interfere with existing circuit breakers. When sourcing these specialised components, a diligent contractor will visit a dedicated electrical wholesaler to ensure every meter and sensor carries the necessary approvals for use in Australia, guaranteeing accuracy and safety.

Meeting Compliance Standards

For new commercial builds or major renovations, EMS installation is often driven by the National Construction Code (NCC), specifically Section J. This section mandates that buildings must have the ability to monitor their energy consumption.

Engaging an expert in electricians EMS installation ensures that your building meets these legal requirements. They will separate the metering for lighting, HVAC, and general power as required by the code. This compliance is not just about passing the final inspection; it is essential for achieving high NABERS energy ratings, which can significantly increase the value and rental appeal of a commercial property.

Safety First

It is important to remember that retrofitting an EMS often involves working on active switchboards to minimise downtime for the business. This is high-risk work.

In Australia, only a licensed electrician can perform this installation. They have the training to work safely around live parts and ensure that the installation does not compromise the integrity of the switchboard or the safety of the building's occupants.

Professional Gear from Schnap Electric

To deliver a successful installation, a contractor needs access to industrial-grade components that are easy to install and proven to last.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They support contractors with a vast range of energy management hardware, including high-precision digital meters, split-core CTs for easy retrofitting, and robust communication cabling. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric helps electricians deliver compliant, high-performance energy management systems. For the best results on your next project, choose the quality range from Schnap Electric.

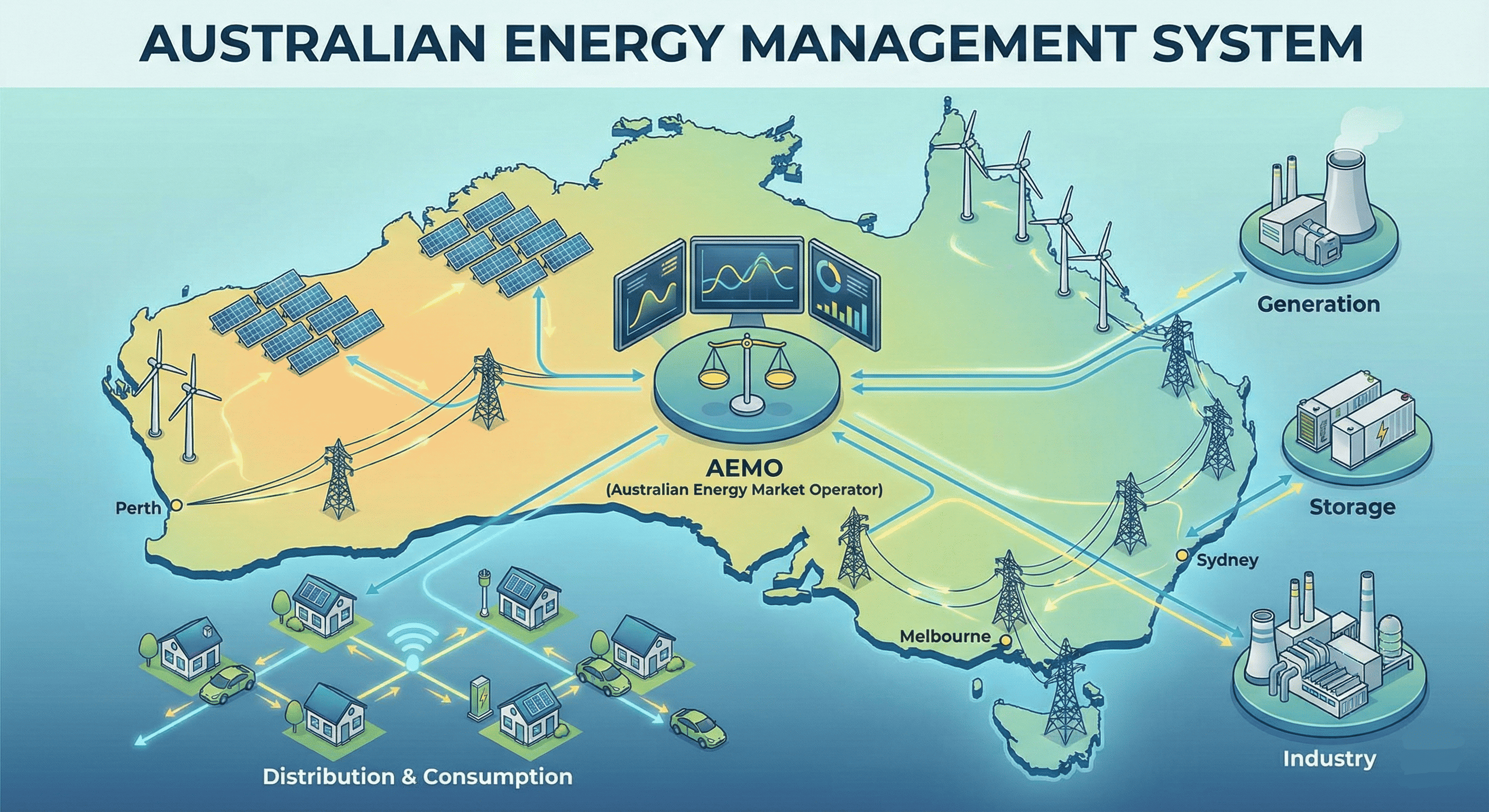

Energy Management System Australia

G'day! It is no secret that the cost of living is a hot topic right now, and for many households and businesses across the country, the quarterly electricity bill is a major source of stress. With prices fluctuating and the grid evolving, simply switching off the lights when you leave a room is no longer enough. To truly make a dent in your expenses, you need to embrace the concept of Energy Management System Australia wide.

This approach is about shifting from a passive consumer to an active manager of your power. By utilising smart technology, real-time data, and automation, Aussies can visualise exactly where their money is going and take concrete steps to stop the waste. Whether you are running a family home in the suburbs or a manufacturing plant in an industrial estate, taking control of your energy profile is the smartest investment you can make.

What Does Energy Management Actually Involve?

At its core, energy management is the process of monitoring, controlling, and conserving energy in a building or organisation. In the past, this was done by reading a meter once every three months. Today, technology allows us to see what is happening second by second.

For residential homes, this involves installing smart monitoring devices in the switchboard that communicate with a smartphone app. You can see if the air conditioner is working too hard or if the pool pump is running during peak tariff times.

For the commercial sector, Energy Management System Australia standards are becoming increasingly sophisticated. Businesses are using Building Management Systems (BMS) to automate lighting, HVAC, and machinery based on occupancy and time of use. This prevents the common scenario of an empty office building being cooled to 18 degrees all weekend.

Maximising the Solar Advantage

Australia has one of the highest rates of rooftop solar adoption in the world. However, many systems are underutilised. With feed-in tariffs (the money you get for selling power back to the grid) dropping significantly, the old "set and forget" strategy doesn't pay off like it used to.

An effective management system is essential for solar owners. It allows for "load shifting." This means the system can identify when your panels are generating excess free power and automatically trigger heavy loads—like the hot water system, EV charger, or dishwasher—to run at that exact moment. This strategy, known as maximising self-consumption, is the golden rule of modern energy efficiency.

Sourcing the Right Technology

To build a system that works, you need reliable hardware. This includes precision energy meters, current transformers, smart relays, and contactors. If the data going into the system is inaccurate, the decisions made by the software will be flawed.

When a professional contractor designs a system, they will typically source these critical components from a trusted electrical wholesaler to ensure they meet the stringent safety and accuracy requirements of the Australian market. Using trade-grade equipment ensures that the system can handle the heat and environmental conditions typical of an Aussie switchboard without failing.

Installation and Safety Regulations

While the data on your screen is easy to read, installing the hardware is serious business. Energy management devices are hardwired directly into the main electrical circuits of your building.

In Australia, it is strictly illegal for a homeowner or business owner to perform their own fixed electrical work. You must engage a licensed electrician to install any monitoring or control equipment. A qualified professional ensures that the installation complies with AS/NZS 3000 Wiring Rules, ensuring that your new efficiency measures do not compromise the safety of your property or family.

Efficient Solutions from Schnap Electric

If you are ready to take control of your power usage, you need components that deliver accurate data and reliable control.

Schnap Electric Products is a premier supplier for the trade industry in Australia. They stock a comprehensive range of energy management solutions, including high-precision digital meters, heavy-duty contactors, and smart relays suitable for both residential solar setups and complex commercial installations. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures you have the tools to monitor, manage, and reduce your energy footprint effectively. For a smarter way to power your property, choose the quality range from Schnap Electric.

Coax

G'day! We spend a motza on massive 4K televisions, high-speed NBN plans, and premium Foxtel packages, yet we often overlook the most critical link in the chain. If your picture is pixelating right at the climax of the footy grand final, or your internet drops out during a video call, the culprit is often that thick, round cable running from the wall to your device. We are talking about coax.

Short for coaxial cable, this robust wire is the backbone of data and video transmission in Australian homes. While Wi-Fi is great for convenience, nothing beats a hardwired coaxial connection for signal strength and reliability. Understanding the difference between a cheap lead and a professional-grade cable can save you a heap of frustration.

What is Coax Cable?

To the untrained eye, coax just looks like a thick wire. However, its internal structure is a clever piece of engineering designed to protect the signal it carries.

In the centre, there is a copper conductor that carries the data or video signal. Surrounding this is a layer of insulation, and wrapped around that is a metal shield (usually foil and braided wire). Finally, a tough outer jacket protects the whole lot. The magic lies in that shield. Its job is to stop outside electrical noise—from 4G mobile towers, power lines, or even your microwave—from interfering with the signal inside.

RG6 vs RG59: Know the Difference

If you live in an older Aussie home, your antenna might still be wired with an old standard known as RG59. This cable is thinner and has less shielding. In the days of analogue TV, it was fine. Today, with high-definition digital TV and high-speed data, RG59 is often the cause of signal loss and interference.

The modern standard is RG6 coax. It has a thicker central conductor and better insulation, allowing it to carry more data over longer distances. For the best possible performance, professional installers use "Quad Shield" RG6. As the name suggests, it has four layers of shielding instead of the standard two. When a professional installer needs to guarantee a perfect signal for a customer, they don't grab cheap cable from a discount bin. They head to a dedicated electrical wholesaler to source high-spec Quad Shield cable that is guaranteed to block out interference.

The NBN Connection

For millions of Australians, coax is more than just a TV cable; it is their internet lifeline. The NBN Hybrid Fibre Coaxial (HFC) network uses the existing high-quality Pay TV cabling network to deliver high-speed internet to your home.

If your NBN connection box is connected to the wall with a flimsy, kinked, or old cable, your internet speed will suffer. Ensuring you have a high-quality RG6 patch lead connecting your wall plate to your modem is one of the cheapest and most effective ways to ensure you are getting the download speeds you pay for.

A Job for the Professionals

While plugging a fly lead from the wall to your TV is a DIY job, installing new outlets or running cable through your roof space is not.

In Australia, any fixed cabling work associated with telecommunications, TV antennas, or data must be performed by a registered licensed cabler. They have the training to ensure the coax is run correctly, maintaining the right bend radius so the internal core isn't damaged. They also ensure it is separated safely from electrical wiring to prevent interference and safety hazards.

Quality Connections from Schnap Electric

A cable is only as good as the connectors on the end. Using cheap, push-on plugs results in a loose connection and signal dropout. You need professional-grade compression fittings that lock onto the cable securely.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of data and visual solutions, including premium Quad Shield coax rolls, professional F-type compression connectors, and the specialist tools needed to terminate them correctly. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your home entertainment and internet signals are strong, clear, and interference-free. For a picture-perfect result, trust the range from Schnap Electric.