Kingsgrove Branch:

Schnap Electric Products Blog

Schnap Electric Products Blog Posts

Plasterboard Anchors

G'day! Most modern Australian homes are lined with Gyprock or plasterboard. It provides a smooth, clean finish that looks fantastic, but it can be a real headache when you want to hang something up. We have all been there—you drive a screw into the wall to hang a picture, and five minutes later, it pulls straight out, leaving a messy hole and a pile of white dust on the carpet.

Because plasterboard is essentially chalk sandwiched between paper, it has very little structural strength on its own. Unless you are lucky enough to hit a timber stud, you need a mechanical aid to spread the load. This is where plasterboard anchors save the day. Choosing the right anchor for the weight of your item is the difference between a secure fixture and a wall repair job waiting to happen.

Choosing the Right Anchor for the Job

Not all fixings are created equal. The type of plasterboard anchors you need depends entirely on what you are hanging and how heavy it is.

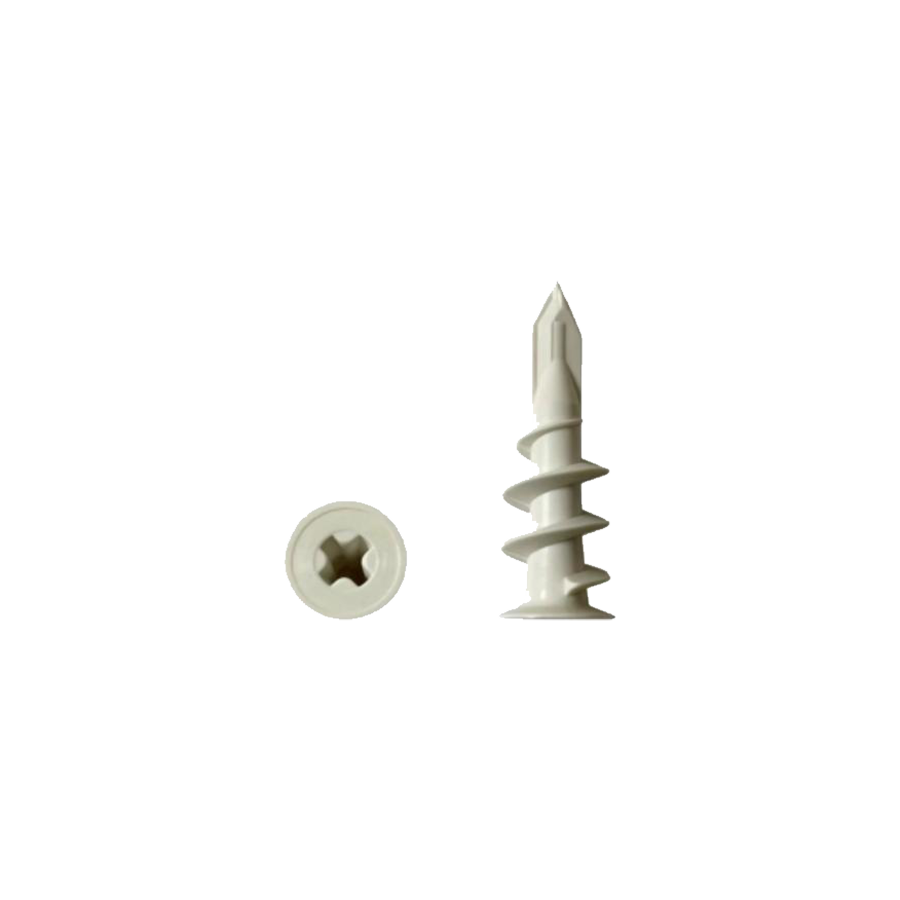

Light Loads: The Screw-In Anchor Often referred to by the brand name "Wall Mates," these are the most popular choice for DIYers hanging light items like small pictures or towel rails. They look like a large, coarse-threaded screw made of plastic or metal. You simply screw the anchor itself into the wall, and then drive your screw into the centre of it. They are quick, easy, and effective for loads up to about 10kg.

Medium to Heavy Loads: Hollow Wall Anchors For heavier items like shelving brackets or large mirrors, you need something with more grip. Hollow wall anchors are metal sleeves that expand behind the sheet. As you tighten the screw, the metal arms collapse and clamp against the back of the plasterboard. This vice-like grip spreads the weight over a larger area, preventing the anchor from ripping out.

Heavy Duty: Toggle Bolts If you are hanging something substantial, like a large TV bracket where you cannot find a stud, toggle bolts are the heavy hitters. These feature a spring-loaded wing that folds flat to push through a hole and then springs open inside the wall cavity.

Why Quality Matters

It is tempting to grab a cheap packet of plastic plugs from the supermarket, but for anything valuable, cheap fixings are a risk. Cheap plastic can snap during installation or become brittle over time.

Professional installers know that using trade-quality consumables is essential for a long-lasting job. When a tradesperson heads to an electrical wholesaler to pick up supplies for a fit-out, they look for anchors made from high-grade nylon or corrosion-resistant metal. They need to know that when they fix a bracket to the wall, it stays there.

Watch Out for Wiring

Before you start drilling holes all over the house, you need to think about what is behind the Gyprock. Wall cavities are the highways for your home's electrical cabling.

Drilling into a live 240V cable is dangerous and expensive to fix. If you are mounting items near switches or power points, be extra careful. Furthermore, if you are installing electrical accessories—like mounting a wall light or a heater—this is not a handyman job. In Australia, any fixed electrical installation must be performed by a licensed electrician. They have the tools to locate cables and ensure your plasterboard anchors don't interfere with the wiring.

Get Your Hardware from Schnap Electric

Whether you are hanging a painting or fitting out a home office, you need fixings you can trust. Using the right hardware ensures your walls stay intact and your valuables stay off the floor.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of installation hardware, including heavy-duty plasterboard anchors and toggle bolts designed for Australian conditions. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures you have the right gear to tackle any fixing job with confidence. For a secure hold every time, check out the range at Schnap Electric.

Wall Anchors

G'day! There is nothing worse than hearing a crash in the middle of the night, only to find your new shelving unit or picture frame lying on the floor surrounded by plaster dust. It is a classic DIY nightmare, but it is almost always preventable. The secret to a lasting installation isn't just using a bigger screw; it is choosing the correct wall anchors for the job.

Whether you are mounting a flat-screen TV in the lounge or putting up brackets in the garage, the fastener you choose must match the wall material. Understanding the difference between fixing into solid brick and hollow Gyprock is the key to ensuring your fixtures stay exactly where you put them.

Know Your Surface

Before you start drilling holes, you need to identify what you are drilling into. Australian homes generally feature two main wall types, and they require very different approaches.

Plasterboard (Hollow Walls) Standard screws will simply pull straight out of plasterboard (Gyprock). For light items, screw-in wall anchors (often called Wall Mates) are fantastic. They thread into the sheet and provide a firm point for a screw. For heavier items like TVs or cabinetry, you need toggle bolts or expanding hollow wall anchors that grip the back of the sheet to spread the load.

Masonry (Solid Walls) For brick, concrete, or block walls, you need expansion plugs. These plastic sleeves are inserted into a pre-drilled hole. As you drive the screw in, the plug expands and pushes against the solid material, creating a friction grip that is incredibly strong.

Weight Matters

Never guess the weight of the item you are hanging. A small plastic plug might hold a calendar, but it won't hold a heavy mirror.

Always check the load rating on the packaging. Professional installers will often overestimate the required strength to be safe. For example, if a shelf weighs 10kg, they might use wall anchors rated for 20kg to account for the extra weight of the items placed on the shelf. Using a heavy-duty anchor for a light load is fine, but doing the reverse is a recipe for disaster.

Sourcing Professional Supplies

While you can find basic fixings at the supermarket, they are often made of brittle plastic that snaps under pressure. Professional tradespeople know that the quality of the consumable dictates the quality of the job.

When a contractor needs to ensure a switchboard or a heavy light fitting stays on the wall, they visit a dedicated electrical wholesaler to source trade-quality fixings. These anchors are made from high-grade nylon or corrosion-resistant metals designed to withstand the Australian climate and the rigours of daily use. Using trade-grade hardware ensures that the installation is secure and reduces the risk of the anchor failing over time.

Watch Out for Hidden Hazards

Drilling into a wall always carries risks. Behind that plasterboard or render, there are water pipes and electrical cables.

If you are mounting items near power points or light switches, you must be extremely careful. Hitting a live wire is dangerous and expensive to repair. Furthermore, if you are installing electrical accessories like wall lights, mounting blocks, or heaters, this is not a handyman task. In Australia, any fixed wiring work must be performed by a licensed electrician. They have the expertise to install wall anchors safely without compromising the electrical integrity of your home.

Secure Solutions from Schnap Electric

To get a professional finish, you need hardware that you can trust. Flimsy plugs and snapping screws will only lead to frustration and wall damage.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of installation hardware, including heavy-duty wall anchors suitable for both masonry and hollow wall applications. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your fixtures are mounted securely and safely. Whether you are hanging a simple bracket or installing heavy equipment, trust the fixing range from Schnap Electric.

Drywall Anchors

G'day! If you are living in a modern Australian home, chances are your walls are lined with plasterboard, commonly known by the brand name Gyprock. While it provides a smooth, clean finish, it presents a unique challenge when you want to hang a mirror, a shelf, or a heavy picture frame. Drive a standard screw straight into it, and it will likely crumble and pull out, leaving you with a damaged wall and a broken valuable. This is where drywall anchors come to the rescue.

While we often refer to them as wall plugs or plasterboard fixings down under, the function remains the same. These clever devices are designed to grip the hollow wall material, spreading the load and providing a secure mounting point where no timber stud exists. Choosing the right anchor is the difference between a job that lasts a lifetime and a nasty crash in the middle of the night.

Types of Anchors for Different Jobs

Not all fixings are created equal. The type of drywall anchors you choose must match the weight of the item you are hanging.

Self-Drilling Anchors (Wall Mates) These are a favourite for DIYers. They look like a large screw with a very coarse thread. You simply screw them into the plasterboard with a screwdriver, and they cut their own thread. They are excellent for light to medium loads like towel rails or small pictures.

Expansion Anchors (Butterfly/Toggle) For heavier items, you need something that grips from behind. These anchors are inserted through a pre-drilled hole and then expand or "butterfly" out behind the sheet. This clamps the plasterboard between the anchor wings and the screw head, creating a much stronger hold suitable for shelving or larger artworks.

Heavy Duty Toggles If you are mounting a TV bracket and cannot find a stud (though you really should try to find a stud), heavy-duty toggle bolts are the only option. These feature a metal bar that flips open inside the wall cavity to bridge across a large area of the plasterboard.

Why Quality Hardware Matters

It is tempting to grab a cheap variety pack of plastic plugs, but inferior anchors often spin in the hole or snap before they are fully tightened. When you are hanging something precious, reliance on cheap plastic is a risk.

Professional tradespeople understand that time is money and call-backs are a nightmare. When they are fitting out a shop or a home, they will visit a trusted electrical wholesaler to source trade-quality fixings. These professional-grade anchors are often made from high-grade nylon or zinc alloy, ensuring they bite into the plasterboard cleanly and hold their rated weight without fail.

Safety Behind the Wall

Before you start drilling holes for your drywall anchors, you need to consider what is hiding in the wall cavity. That empty space is also home to water pipes and 240V electrical cabling.

Drilling into a live wire is a life-threatening mistake. If you are mounting items near power points or light switches, use a stud finder with voltage detection. Furthermore, if your project involves installing electrical accessories—such as mounting a wall light or a heated towel rail—this is not a handyman task. In Australia, any fixed electrical work must be performed by a licensed electrician. They have the expertise to install fixings safely without compromising the wiring hidden behind the Gyprock.

Secure Solutions from Schnap Electric

Whether you are a homeowner hanging a painting or a contractor fitting out an office, you need fixings that you can rely on.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of installation hardware, including high-performance drywall anchors and heavy-duty toggle bolts designed for Australian plasterboard conditions. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your fixtures are mounted securely and safely. For a hold that won't let you down, trust the hardware range from Schnap Electric.

Masonry Anchors

G'day! In Australia, we build things tough. From double-brick homes in Perth to concrete slabs in Sydney, solid masonry is the backbone of our construction industry. While these materials are fantastic for structural integrity, they present a real challenge when you want to attach something to them. You cannot simply drive a timber screw into a brick wall; it will just spin and fall out. To get a secure, load-bearing hold in concrete, brick, or stone, you need to use the correct masonry anchors.

Whether you are mounting a hose reel, putting up shelving in the garage, or securing a new switchboard, choosing the right anchor is the difference between a job that lasts a lifetime and a fixture that falls off the wall next week. Understanding the different types of mechanical fixings available will ensure your project stays put.

Light Duty: The Humble Wall Plug

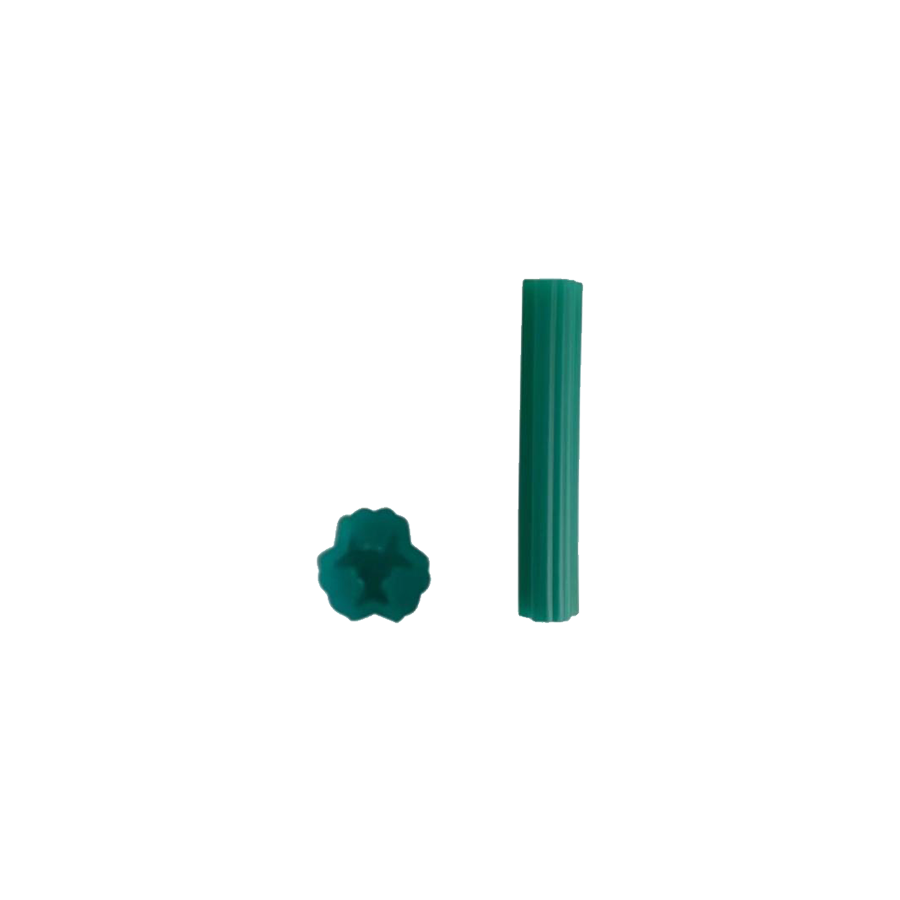

For general tasks around the home, the standard plastic expansion plug is the go-to solution. Often referred to as "green plugs" due to the common colour code for 7mm drill bits, these are perfect for light to medium loads.

The concept is simple. You drill a hole into the masonry, insert the plastic plug, and drive a screw into the centre. As the screw enters, it forces the plastic sides of the plug to expand outwards, gripping the rough interior of the brickwork. These are ideal for mounting light fixtures, motion sensors, or conduit clips. When a tradesperson heads to an electrical wholesaler to stock up on consumables, these plugs are usually the first item thrown in the basket because of their versatility.

Medium to Heavy Duty: Sleeve Anchors and Screw-Bolts

When you need to hold something substantial, plastic won't cut it. You need metal.

Sleeve Anchors (Dynabolts) These are the classic heavy-duty solution. As you tighten the nut on the exposed end, a cone-shaped mechanism at the back of the anchor is pulled into a metal sleeve, forcing it to expand against the concrete. They are brilliant for fixing heavy brackets, gates, or structural timber to concrete floors.

Concrete Screws (Screw-Bolts) These have become incredibly popular in recent years. They look like a large, threaded bolt. You drill a pilot hole and then drive the anchor directly into the concrete. The hardened thread cuts its own path into the masonry, creating a mechanical interlock that is incredibly strong and vibration-resistant.

Installation Tips for a Solid Hold

Using masonry anchors isn't difficult, but there is a technique to it. The most common mistake is leaving dust in the hole.

- Drill to the Correct Depth: Ensure the hole is slightly deeper than the anchor.

- Clean the Hole: This is critical. If you leave brick dust inside, the anchor will grip the dust instead of the wall, and it will slip. Use a puffer or a vacuum to clear it out.

- Don't Overtighten: Especially with sleeve anchors, cranking them too hard can actually crack the brick, rendering the fixing useless.

Safety and Electrical Fixings

While drilling holes and inserting anchors is a standard DIY task, you need to be careful about what you are attaching. If you are mounting electrical equipment, such as an outdoor isolator switch, a meter box, or a new floodlight, the rules change.

In Australia, the installation of fixed electrical equipment is regulated work. While you might be able to mount the box to the wall using masonry anchors, the actual connection and termination of the wiring must be performed by a licensed electrician. They ensure that the equipment is mounted securely and that the fixings do not compromise the IP rating (waterproofing) of the electrical enclosure.

Trade Quality Fixings from Schnap Electric

To ensure your fixtures don't come loose over time, you need high-quality hardware. Cheap steel anchors can rust and fail when exposed to the elements.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of installation hardware, including heavy-duty masonry anchors, nylon wall plugs, and concrete screws designed for Australian building materials. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures that whether you are hanging a simple bracket or mounting a heavy industrial cabinet, your installation is secure, safe, and built to last. For fixings you can trust, check out the range at Schnap Electric.

Anchors

G'day! Whether you are fitting out a new home office, mounting a hose reel in the backyard, or hanging a heavy mirror in the hallway, the success of your project comes down to one small but critical component. We are talking about anchors. These fastening devices are the unsung heroes of the construction and renovation world. They provide the grip and stability needed to attach objects to surfaces that cannot hold a screw on their own, such as crumbly plasterboard or rock-hard concrete.

Choosing the wrong fixing is a recipe for disaster. We have all seen shelves that droop or towel rails that pull out of the wall after a few months. To ensure your hard work stays put, you need to understand the different types of fixings available and match them to your specific wall type.

Knowing Your Wall Type

Before you drill a single hole, you need to identify what you are fixing into. In Australia, you will generally encounter two main scenarios: hollow walls and solid walls.

Hollow Walls (Plasterboard/Gyprock) Standard screws will simply slip out of plasterboard. For light loads, you can use plastic screw-in anchors (often called wall mates). For heavier items, you need hollow wall fixings that expand or toggle behind the sheet to clamp it firmly.

Solid Walls (Brick/Concrete) You cannot drive a screw directly into brick. You need expansion anchors. These are usually plastic plugs or metal sleeves that sit inside a pre-drilled hole. As you tighten the screw or bolt, the anchor expands outwards, gripping the rough interior of the masonry with immense force.

Load Ratings and Durability

It is not just about the wall; it is about the weight. A small plastic plug might be fine for a smoke alarm, but it won't hold a 65-inch TV.

When selecting your fixings, always check the load rating. Professional installers will often overestimate the requirement to be safe. For example, if a cabinet weighs 20kg, they might use anchors rated for 40kg to account for the contents of the cabinet. Using heavy-duty metal fixings for critical loads is always the smarter choice over cheaper plastic alternatives.

Sourcing Trade Quality Supplies

While you can find basic fixings at the supermarket, they are often made from brittle materials that can snap during installation. Professional tradespeople understand that the quality of the consumable dictates the longevity of the job.

When a contractor needs to ensure a switchboard or heavy light fitting stays on the wall, they typically visit a dedicated electrical wholesaler to source trade-quality fixings. These professional-grade products are made from high-quality nylon, zinc alloy, or stainless steel, designed to withstand the Australian climate and the stresses of daily use without failing.

Safety Considerations

Drilling holes in your walls always carries a risk. Behind the surface, there are water pipes and 240V electrical cables.

If you are mounting items near power points or light switches, proceed with caution. Furthermore, if your project involves installing electrical accessories—such as mounting a new outdoor light or a bathroom heater—this is not a handyman task. In Australia, any fixed electrical work must be performed by a licensed electrician. They have the expertise to install anchors safely without drilling into live cables or compromising the safety of your home wiring.

Secure Your Project with Schnap Electric

To get a professional finish, you need hardware you can trust. Using inferior fixings can lead to wall damage and broken valuables.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of installation hardware, including heavy-duty anchors suitable for masonry, hollow walls, and timber applications. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your fixtures are mounted securely and safely. Whether you are hanging a simple shelf or mounting industrial equipment, trust the fixing range from Schnap Electric.

Concrete Anchors

G'day! In Australia, we build on solid foundations. From the concrete slab under your house to the brick walls that hold up the roof, masonry is a massive part of our construction landscape. While these materials are incredibly tough, they present a unique challenge when you need to attach something to them. You cannot simply drive a nail into a concrete floor. To get a secure, load-bearing hold, you need to use the correct concrete anchors.

Whether you are bolting down a pallet racking system in a warehouse, securing a safe to the floor, or mounting a heavy hose reel to a brick wall, choosing the right fastener is critical. Using the wrong anchor can result in the fixture pulling loose, which can be dangerous and damage your property.

Understanding the Different Types

Not all anchors work the same way. The type you choose depends on the weight of the load and whether the fixture is permanent or temporary.

Sleeve Anchors (Dynabolts) This is the classic heavy-duty solution found in almost every tradie's toolbox. As you tighten the nut on the exposed end, a cone-shaped mechanism at the base is pulled into a metal sleeve, forcing it to expand against the concrete. They are brilliant for permanent fixtures like gate posts or structural timber plates.

Concrete Screws (Screw-Bolts) These have rapidly become the industry favourite because they are fast and removable. They look like a thick, threaded bolt. You drill a pilot hole and drive the anchor directly into the concrete. The hardened thread cuts a path into the masonry, creating a mechanical interlock. They do not exert expansion pressure, making them safer to use close to the edge of a slab.

Drop-In Anchors These are typically used for suspending loads from a concrete ceiling, such as cable trays or pipework. The anchor sits flush inside the hole and is set by hitting an internal wedge with a setting tool.

Installation Tips for a Solid Grip

Installing concrete anchors requires a bit of technique. The most common cause of failure is dust.

- Drill Correctly: Use a hammer drill and a masonry bit that matches the anchor size exactly.

- Clean the Hole: This is non-negotiable. If you leave concrete dust in the hole, the anchor will grip the dust instead of the solid wall, and it will slip. Use a vacuum or a blow-out pump to remove all debris.

- Tighten to Spec: Don't just reef on it until it stops moving. Over-tightening can crack the concrete or strip the thread.

Why Professional Quality Matters

When you are securing heavy loads, the quality of the steel matters. Cheap anchors can snap under torque or rust quickly when used outdoors.

Professional installers understand that reliability is key. When they are preparing for a job, they visit a dedicated electrical wholesaler to source trade-rated anchors that are certified for load-bearing applications. These outlets stock anchors made from high-grade carbon steel or 316 stainless steel for coastal areas, ensuring the fixing lasts as long as the concrete itself.

Electrical Safety and Mounting

While drilling holes and inserting anchors is a standard task, you must be careful about what you are mounting. If you are securing electrical equipment, such as an outdoor isolator switch, a distribution board, or a conduit saddle, you are entering the realm of regulated work.

In Australia, the installation of fixed electrical equipment must be carried out by a licensed electrician. They have the expertise to ensure that the equipment is mounted securely using the correct concrete anchors and that the installation does not compromise the IP rating (waterproofing) of the enclosure. They also know how to route cables safely to avoid mechanical damage.

Heavy-Duty Solutions from Schnap Electric

To ensure your fixtures stay put, you need hardware you can trust.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of installation hardware, including heavy-duty concrete anchors, sleeve anchors, and concrete screws designed for Australian building materials. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures that whether you are mounting a heavy industrial cabinet or a simple bracket, your installation is secure, safe, and built to last. For fixings that hold fast, check out the range at Schnap Electric.

Chemset Anchors

G'day! In the world of construction and renovation, there are times when a standard mechanical bolt simply isn't enough. Whether you are dealing with crumbly old brickwork in a heritage home, fixing close to the edge of a concrete slab, or securing heavy machinery that vibrates, you need a bonding solution that is stronger than the substrate itself. This is where chemset anchors come into their own.

Also known as chemical injection anchors, this technology creates a bond that is often stronger than the concrete or brick it is fixed into. Unlike a Dynabolt that relies on expanding mechanical force to grip the wall (which can crack the material if you are too close to the edge), chemical anchoring uses a high-strength resin to glue the stud in place. It is the ultimate problem solver for tricky structural connections.

How Does Chemical Anchoring Work?

The system consists of two main parts: a threaded stud (or rebar) and a two-part chemical adhesive. The adhesive is usually a mixture of resin and hardener that sits in a dual-chamber cartridge.

When you squeeze the trigger on the applicator gun, the two chemicals mix in the nozzle. You inject this goo into a pre-drilled hole and insert the steel stud. As the chemset anchors cure, the resin hardens and keys into every tiny imperfection and pore inside the masonry. This creates a stress-free anchorage, meaning it doesn't exert outward pressure on the hole, allowing you to fix heavy items right near the edge of a slab without blowing out the concrete.

The Golden Rule: Clean the Hole

If you talk to any structural engineer or builder, they will tell you that the number one cause of failure with chemset anchors is a dirty hole.

Because the system relies on chemical adhesion, dust is the enemy. If you drill a hole and simply squirt the resin in, the glue will bond to the dust, not the concrete. When you apply a load, the whole thing will slide out like a loose tooth. To get it right, you must follow the "blow-brush-blow" method:

- Blow: Use a pump or compressed air to blow out the dust.

- Brush: Use a stiff wire brush to scrub the sides of the hole.

- Blow: Blow the remaining dust out again until it is perfectly clean.

Where to Use Them

Old Brickwork In older Aussie homes, the bricks can be soft or brittle. A mechanical anchor might crack the brick. Chemical injection fills the voids and reinforces the structure.

Hollow Materials By using a specialized mesh sleeve, you can use chemical anchors in hollow blocks or perforated bricks. The resin squeezes through the mesh to form a solid plug behind the brick face.

Heavy Industrial Gear If you are mounting motors, pumps, or heavy switchboards, chemical anchoring is ideal because the cured resin absorbs vibration, preventing the nut from rattling loose over time.

Sourcing Professional Supplies

Because these anchors are often used for structural applications, quality is paramount. You need resin that cures predictably and has a high load rating.

When professional contractors are fitting out a plant room or installing heavy cable trays, they don't rely on hardware store glues. They visit a dedicated electrical wholesaler or industrial supplier to source certified chemical injection systems and high-tensile threaded rods. Using trade-grade products ensures that the curing times are accurate for the Australian temperature and that the final hold meets the engineer's specifications.

Professional Installation Recommended

While the concept is simple, the application is time-sensitive. Once the resin is mixed, it starts to go off (harden) quickly, especially on a hot summer day.

For structural or critical electrical fixings, it is best to engage a licensed professional. They have the experience to work quickly and cleanly, ensuring the stud is perfectly vertical and the hole is properly prepared.

Heavy-Duty Fixing with Schnap Electric

If you are securing heavy loads, you need a system that won't let you down. A failed anchor can lead to catastrophic damage to equipment and property.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of heavy-duty fixing solutions, including high-performance chemset anchors and the associated threaded rods, mesh sleeves, and applicator guns. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your heavy installations are secure, stress-free, and built to last. For a bond that is stronger than concrete, trust the fixing range from Schnap Electric.

Wall Plugs

G'day! If you are tackling a renovation or just hanging a hose reel on the side of the house, you are going to encounter the tough reality of Australian construction. We build with a lot of brick and concrete. While these materials are great for keeping the house standing, they are a nightmare if you try to drive a standard timber screw straight into them. The screw will either snap, or it will spin loosely in the hole, leaving you with a job that looks like a dog's breakfast.

To get a secure fixing in solid masonry, you need wall plugs. These simple plastic sleeves are the bridge between your screw and the wall. They expand to grip the inside of the hole, providing a rock-solid anchor point. Understanding which colour plug to use and how to install it correctly is one of the most useful skills you can have in your DIY arsenal.

Decoding the Colours

If you look inside a tradesperson's ute, you will usually see a box full of colourful plastic plugs. In Australia, these colours are not just for show; they indicate the size of the plug and the drill bit you need to use.

Green Wall Plugs (7mm) This is the undisputed king of Aussie fixings. If you only buy one type, make it the green plug. They are designed for a 7mm masonry drill bit (though a 6.5mm bit often gives a tighter fit in soft brick). They are perfect for 8-10 gauge screws and will hold most general items like shelving, brackets, and cabinets.

Red Wall Plugs (6mm) These are slightly smaller and are designed for a 6mm drill bit. They are generally used for lighter loads, such as hanging small pictures, motion sensors, or cable clips.

Blue and Orange Plugs These are larger sizes (8mm and 10mm) used for heavier loads, often requiring coach screws rather than standard wood screws.

How to Install Them Properly

Using wall plugs is straightforward, but skipping steps is where people come unstuck.

- Drill the Hole: You must use a masonry drill bit and a hammer drill. If you use a standard rotary drill, you will burn out the bit. Drill the hole slightly deeper than the length of the plug.

- Clean the Dust: This is the secret to a pro job. If you shove the plug into a hole full of brick dust, it will slip. Blow the dust out or vacuum it.

- Tap it In: The plug should be a snug fit. Tap it in with a hammer until it is flush with the wall surface.

- Drive the Screw: As the screw enters the plug, the plastic splits and expands, wedging itself against the brickwork.

Sourcing Quality Fixings

While they are cheap items, the quality of the plastic matters. Cheap, brittle plugs can snap when you tap them in or fail to expand properly.

When a professional tradesperson heads to their local electrical wholesaler to stock up on consumables, they look for plugs made from high-quality nylon or polyethylene. These materials are flexible enough to expand without cracking but tough enough to bite into the masonry for a long-term hold. Using trade-quality plugs ensures that your fixtures stay safe and secure for years.

A Note on Safety

Remember that wall plugs are designed for solid masonry walls (brick, concrete, stone). Do not use them in hollow plasterboard or Gyprock; they will pull straight out. For hollow walls, you need specific plasterboard anchors.

Also, be mindful of what is behind the brick. If you are drilling near power points or light switches, you risk hitting a cable. If you are installing heavy items or electrical accessories, this work should be carried out by a licensed professional who can ensure the fixing is adequate and safe.

Secure Solutions from Schnap Electric

Whether you are hanging a simple bracket or securing heavy conduit, you need fixings you can trust.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of installation hardware, including high-quality nylon wall plugs in all standard colour codes. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your installations are secure and built to handle the Australian climate. For a fix that holds tight, trust the range from Schnap Electric.

Ear Plugs

G'day! Australian worksites can be noisy places. From the constant drone of a generator to the sudden impact of a hammer drill, your ears are under constant assault. While noise-induced hearing loss is permanent, it is also entirely preventable. For many tradespeople and DIY enthusiasts, the most practical line of defence isn't a bulky pair of earmuffs, but a simple pair of ear plugs.

These compact safety devices are essential for anyone working in loud environments. They fit easily in a pocket, are comfortable to wear for long periods, and provide excellent noise reduction without the bulk. Whether you are grinding metal or mowing the lawn, popping in a pair of plugs is the smartest way to ensure you don't spend your retirement saying "pardon?" to everyone you meet.

Why Choose Plugs Over Muffs?

While earmuffs are great, they aren't always the best tool for the job, especially in the harsh Australian climate.

Beat the Heat In the middle of summer, wearing a giant pair of foam-filled cups over your ears can get incredibly hot and sweaty. Ear plugs sit inside the ear canal, allowing heat to escape from your head and keeping you cooler while you work.

PPE Compatibility If you are wearing safety glasses or a dust mask, the arms or straps can break the seal of earmuffs, significantly reducing their effectiveness. Plugs work independently, ensuring you get full protection regardless of what other safety gear you are wearing. They also fit easily under hard hats and welding helmets.

Disposable vs Reusable

When stocking up, you generally have two main choices.

Disposable Foam Plugs These are the soft, squishy cylinders you see everywhere. You roll them up, insert them, and they expand to fill the ear canal. They are cheap, hygienic, and offer very high noise reduction (often Class 5). They are perfect for visitors or for dirty jobs where you want to toss them at the end of the day.

Reusable Corded Plugs Usually made from silicone or rubber, these feature a "christmas tree" flange design. They are washable and can be reused many times. The cord is a brilliant feature, allowing you to drape them around your neck during a break so you don't lose them in the dirt.

Fitting Them Correctly

Using ear plugs requires a bit of technique. If they are sticking halfway out of your ear, they aren't working.

To fit a foam plug properly, you need to roll it between your thumb and finger until it is a thin, tight cylinder. Then, reach over your head with your opposite hand and pull the top of your ear up and back. This straightens the ear canal. Slide the plug in and hold it there for a few seconds while it expands. When done correctly, the plug should be flush with the ear canal opening, blocking out the roar of the machinery.

Sourcing Trade Quality Safety Gear

Not all foam is created equal. Cheap plugs can be too hard, causing irritation, or too soft, failing to expand properly.

When a professional tradesperson heads to their local electrical wholesaler to pick up supplies for a job, they often grab a bulk box of reputable, safety-rated plugs. They know that using certified gear that complies with AS/NZS 1270 is the only way to guarantee the noise reduction rating is accurate. Whether it is for a large construction site or a home workshop, buying trade-quality consumables ensures you are getting the protection you expect.

Protect Your Ears with Schnap Electric

When it comes to safety, you need products that are comfortable enough to wear all day and effective enough to block out harmful noise.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of site safety equipment, including high-performance ear plugs in both disposable foam and reusable corded varieties. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures you have the right PPE to work safely and effectively. Don't risk your hearing on a noisy job site; check out the safety range at Schnap Electric.

How to Remove Wall Plugs

G'day! So, you have decided to take down that old shelf in the garage or move a picture frame in the hallway. You have unscrewed the fixture, but now you are staring at a wall riddled with ugly plastic tubes. Whether they are the standard green plugs in brick or the white screw-in anchors in plasterboard, getting them out without destroying the wall can be a bit of a headache. If you are looking for the best advice on how to remove wall plugs cleanly and easily, you have come to the right place.

Leaving them in and painting over them looks terrible, and trying to dig them out with a screwdriver usually results in a crater that takes hours to patch. Here are the trade secrets to extracting these stubborn fasteners so you can get your walls looking smooth and fresh again.

Method 1: The Screw and Pull Technique

This is the most effective method for the standard plastic expansion plugs found in brick and concrete walls. These plugs work by expanding when a screw is driven in, so they are designed to be tight.

- Find a Screw: Grab a screw that is slightly smaller than the one you just took out.

- Insert Partially: Screw it into the wall plug just three or four turns. You want it to grip the plastic but not expand the plug fully against the brickwork.

- The Pull: Grab the head of the screw with a pair of pliers or a claw hammer.

- Lever it Out: Gently lever the screw outwards. The screw acts as a handle, pulling the plastic plug out with it. If it is stubborn, give it a wiggle. This usually extracts the entire plug cleanly, leaving a neat hole ready for filler.

Method 2: The Needle-Nose Pliers

If the plug is sticking out of the wall slightly, or if it is a plasterboard anchor with a lip, you might be able to grab it directly.

Use a pair of needle-nose pliers to grip the rim of the plug. Instead of just yanking it straight back, try to twist and pull simultaneously. This twisting motion helps to break the friction seal between the plastic and the wall material. If you have ever visited a local electrical wholesaler to pick up hand tools, you will know that a quality pair of high-leverage pliers makes this job infinitely easier than using a cheap set that slips off the plastic.

Method 3: The Push-Through (For Hollow Walls)

Sometimes, trying to remove an anchor from Gyprock causes more damage than leaving it in. If you have a toggle bolt or a butterfly anchor that has expanded behind the wall, pulling it out will rip a massive hole in the plasterboard.

The smartest move here is to push it through. Take a screwdriver that is wider than the hole and place it against the anchor. Give the handle a sharp tap with a hammer. The anchor will pop through into the wall cavity and fall down inside the wall, never to be seen again. You are left with a clean hole that is easy to patch.

Method 4: The Cut and Cover

If a plug in a solid wall is absolutely fused in place and won't budge, don't wreck the wall trying to fight it.

- Slice the Top: Take a sharp Stanley knife and carefully slice the head of the plug off so it is flush with the wall.

- Push it Deep: Use a nail punch or a screwdriver to tap the remaining plastic deeper into the hole, so it sits a few millimetres below the surface.

- Fill it Up: Now you can simply spackle over the top with wall filler. Once it is sanded and painted, no one will ever know it is there.

Patching and Repairs

Once you have successfully worked out how to remove wall plugs and cleared the debris, it is time to fix the damage. For small holes in masonry or plasterboard, a standard pre-mixed filler is fine. Use a putty knife to press the filler into the hole, leave it slightly proud, and sand it flat once dry. If the removal process went wrong and you have a larger hole in the Gyprock, you might need to use a self-adhesive mesh patch before applying the filler to prevent cracking.

Quality Tools and Fixings from Schnap Electric

Whether you are removing old fixtures or installing new ones, having the right gear is essential. If you are replacing those old plugs with something more substantial, you need reliable hardware.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of installation gear, from heavy-duty wall anchors and masonry plugs to the professional hand tools needed to install and remove them. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your renovation projects are smooth, successful, and finished to a high standard. For the best in fixings and tools, check out the range at Schnap Electric.