Kingsgrove Branch:

Schnap Electric Products Blog

Schnap Electric Products Blog Posts

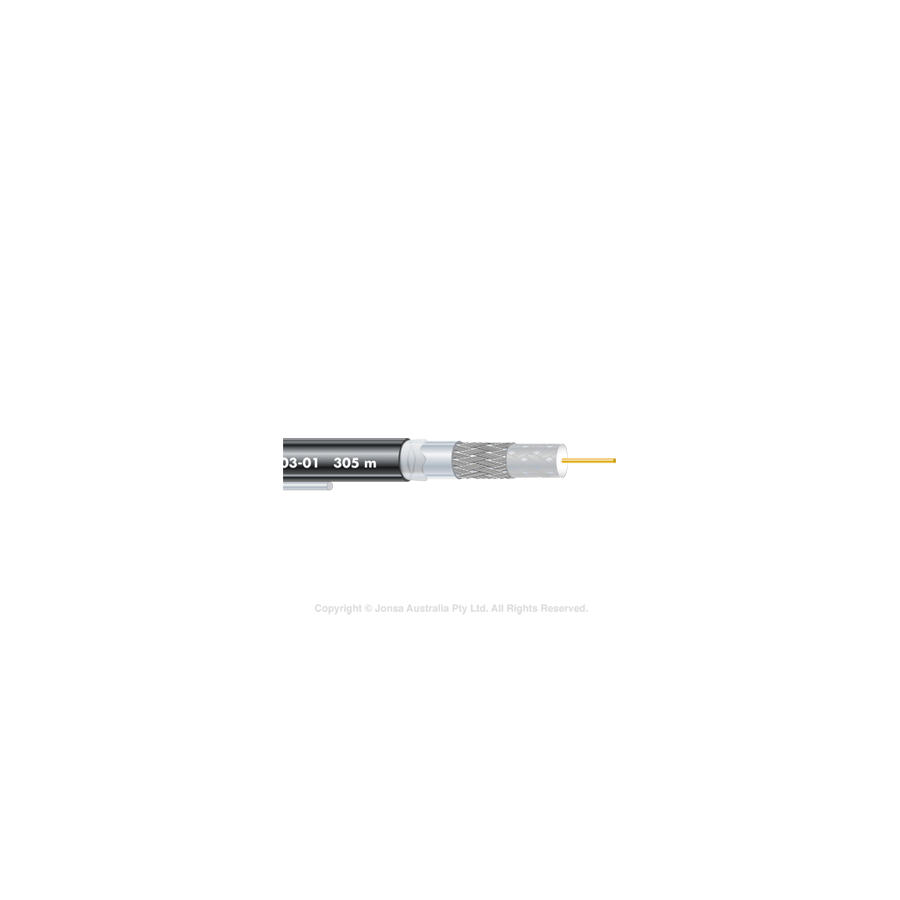

Coax Cable

G'day! We invest a fair bit of cash into massive 4K televisions, premium streaming subscriptions, and high-speed NBN plans, yet we often ignore the most critical physical link in the chain. If your picture pixelates right at the climax of the movie or your internet drops out during a Zoom call, the culprit is often that thick, round cable running from the wall to your device. We are talking about the humble coax cable.

Short for coaxial cable, this robust wire is the unsung hero of data and video transmission in Australian homes. While wireless technology is convenient, nothing beats a hardwired coaxial connection for signal integrity and reliability. Understanding the difference between a cheap fly lead and a professional-grade cable can save you a heap of frustration.

What Exactly is a Coax Cable?

To the untrained eye, coax cable just looks like a thick, stiff wire. However, its internal structure is a clever piece of engineering designed to protect the signal it carries from the outside world.

In the centre, there is a copper conductor that carries the data or video signal. Surrounding this is a layer of plastic insulation, and wrapped around that is a metal shield (usually a combination of foil and braided wire). Finally, a tough outer jacket protects the whole lot from the elements. The magic lies in that shield. Its job is to stop outside electrical noise—from mobile towers, power lines, or even your kitchen microwave—from interfering with the signal inside.

RG6 vs RG59: Know the Standard

If you live in an older Aussie home, your TV antenna might still be wired with an old standard known as RG59. This cable is thinner and has less shielding. In the days of analogue TV, it was fine. Today, with high-definition digital TV and high-speed data, RG59 is often the cause of signal loss and interference.

The modern standard for any new installation is RG6 coax cable. It has a thicker central conductor and better insulation, allowing it to carry more data over longer distances. For the best possible performance, professional installers use "Quad Shield" RG6. As the name suggests, it has four layers of shielding instead of the standard two, providing maximum protection against interference.

The NBN Connection

For millions of Australians, this cable is more than just for TV; it is their internet lifeline. The NBN Hybrid Fibre Coaxial (HFC) network uses the existing high-quality Pay TV cabling network to deliver high-speed internet to your home.

If your NBN connection box is connected to the wall with a flimsy, kinked, or old cable, your internet speed will suffer. Ensuring you have a high-quality RG6 patch lead connecting your wall plate to your modem is one of the cheapest and most effective ways to ensure you are getting the download speeds you pay for.

A Job for the Professionals

While plugging a lead from the wall to your TV is a DIY job, installing new outlets or running cable through your roof space is not.

In Australia, any fixed cabling work associated with telecommunications, TV antennas, or data must be performed by a registered licensed cabler. They have the training to ensure the coax cable is run correctly, maintaining the right bend radius so the internal core isn't damaged. They also ensure it is separated safely from electrical wiring to prevent interference and safety hazards. When a professional plans a job, they visit a reputable electrical wholesaler to source certified cable that meets Australian Standards, ensuring the installation is compliant and safe.

Quality Connections from Schnap Electric

A cable is only as good as the connectors on the end. Using cheap, push-on plugs results in a loose connection and signal dropout. You need professional-grade compression fittings that lock onto the cable securely.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of data and visual solutions, including premium Quad Shield coax cable rolls, professional F-type compression connectors, and the specialist tools needed to terminate them correctly. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your home entertainment and internet signals are strong, clear, and interference-free. For a picture-perfect result, trust the range from Schnap Electric.

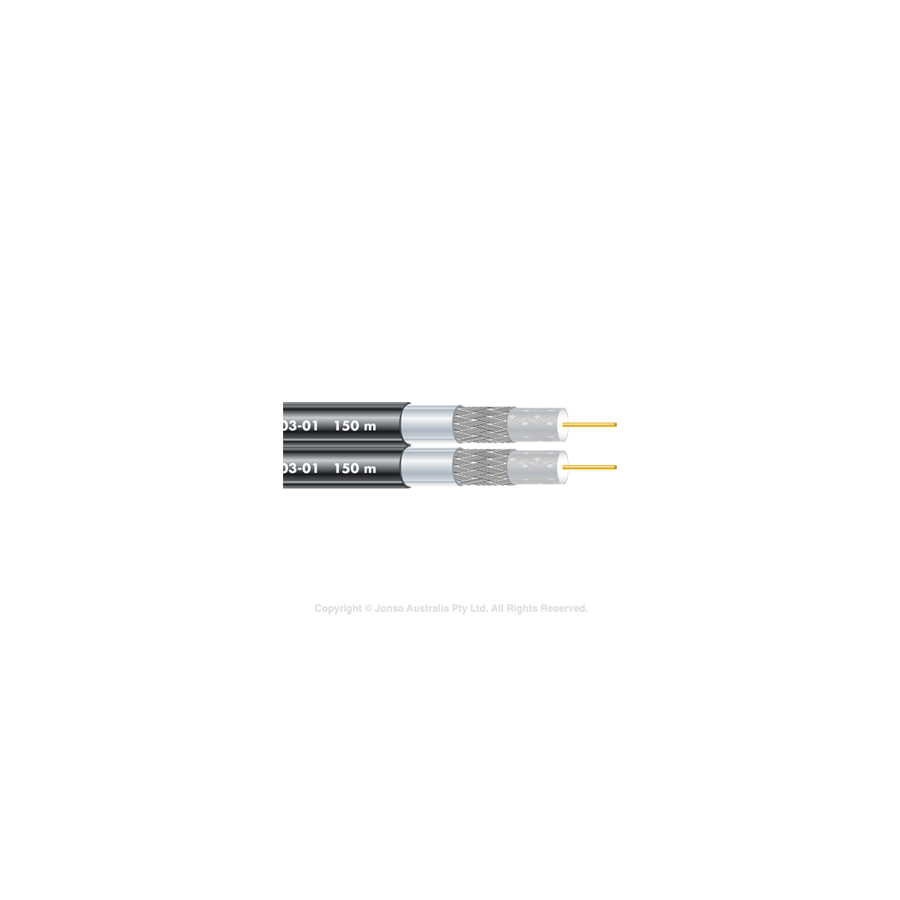

Coax Splitter

G'day! There is nothing worse than arguing over the remote control when the footy is on but the kids want to watch a movie. In the modern Australian home, having multiple televisions is pretty standard. We often want a TV in the lounge, one in the master bedroom, and maybe even one out in the shed for the weekend BBQ. However, most homes only have one antenna on the roof.

To share that single signal across multiple screens, you need a specific piece of hardware known as a coax splitter. While it looks like a simple metal box, choosing the right one is critical. A cheap, nasty unit will ruin your digital reception, leading to pixelation and dropouts right at the best part of the show.

How Does It Work?

A coax splitter does exactly what it says on the tin. It takes the single coaxial feed coming from your roof antenna and divides it into two or more separate outputs.

Inside the metal housing is a circuit that distributes the signal frequency. You will typically find 2-way, 3-way, 4-way, and even 8-way splitters. It allows you to run a cable from the main wall socket to a second location, or if installed in the roof cavity, it directs the antenna signal to different rooms in the house.

The Catch: Signal Loss

There is no such thing as a free lunch when it comes to physics. When you split a signal, you weaken it.

Every time you use a coax splitter, you introduce "insertion loss." For a standard 2-way splitter, you are effectively cutting the signal strength in half (a loss of about 3.5dB). If you use a 4-way splitter, you lose even more.

If you are in a strong signal area, like the middle of Sydney or Melbourne, this usually isn't a problem. However, if you are in a regional area with a weak signal, splitting it might drop the quality below the digital threshold, causing your TV to display "No Signal." In these cases, you might need a powered splitter (distribution amplifier) to boost the signal before splitting it.

F-Type vs PAL

When you head into a shop to buy one, you will see two main types of connections.

PAL (Belling-Lee): These are the old-school, push-on connectors. They are fine for plugging into the back of the TV, but they are not great for splitting signals as they can easily fall out or wobble, causing interference.

F-Type: This is the modern standard for digital TV and Foxtel. These connectors screw onto the splitter, providing a solid, shielded mechanical connection. Any professional installer or staff member at an electrical wholesaler will tell you to stick with F-Type splitters for a reliable, interference-free connection.

Installation Rules

If you are simply plugging a splitter into an existing wall plate to run a second TV in the same room, that is a perfectly safe DIY job.

However, if you are climbing into the roof to cut the main antenna cable and install a coax splitter to run new cables inside the walls to different rooms, you must stop. In Australia, installing fixed cabling for telecommunications or broadcasting (including TV antennas) is regulated work. You must engage a registered licensed cabler. They have the testing equipment to ensure the signal strength is adequate at every wall point.

Get the Right Signal with Schnap Electric

To ensure your TV picture stays crisp and clear, you need high-quality components that are shielded against interference from 4G mobile signals.

Schnap Electric Products is a premier supplier for the trade industry in Australia. They stock a comprehensive range of audio-visual and data solutions, including professional-grade coax splitter units with F-Type connections. By providing the same trade-quality equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your home entertainment system performs perfectly. Whether you are setting up a man cave or fitting out a new build, trust the quality range from Schnap Electric.

Coax Meaning

G'day! In the modern Aussie home, we are surrounded by cables. There are charging cords, power leads, and data cables everywhere. But there is one specific type of cable that does the heavy lifting when it comes to delivering your entertainment and high-speed internet. We are talking about the coaxial cable, or as it is commonly known, "coax."

While you might just see it as the thick white or black wire plugged into the back of your telly or NBN box, understanding the coax meaning and construction helps you appreciate why this specific design is still the industry standard for transmitting high-frequency signals without interference.

So, What Does "Coaxial" Actually Mean?

The word "coaxial" is a geometric term. It describes a system where two or more forms share a common axis. In the context of this cable, it refers to the physical layout of the internal components.

If you were to slice a piece of coax open, you would see four distinct layers, all circular and sharing the same centre point:

- The Centre Conductor: A solid copper wire in the middle that carries the video or data signal.

- The Dielectric Insulator: A thick layer of plastic foam that surrounds the copper core, keeping it centred and electrically isolated.

- The Shield: A layer of metal foil and braided wire mesh that wraps around the insulator.

- The Jacket: The tough outer plastic coating that protects the cable from the elements.

The coax meaning essentially describes this architecture. The inner conductor and the outer shield share the same geometric axis, which is crucial for the physics of how the cable blocks out interference.

Why the Shield is the Hero

The reason we use this bulky cable instead of a thin wire is all about that shield layer. Its job is to act as a Faraday cage, trapping the signal inside the cable and keeping unwanted "noise" out.

In a typical Australian home, the airwaves are full of interference from 4G mobile towers, Wi-Fi routers, and even microwave ovens. Without that heavy-duty shielding, your TV picture would be a pixelated mess and your internet would drop out constantly. When you visit a trade-focused electrical wholesaler to buy cable, you will often hear them talk about "Quad Shield." This is a premium type of coax with four layers of shielding, offering the ultimate protection against signal interference.

Where is it Used?

This cable is the workhorse of the communications industry. You will find it used for:

- Television: Connecting your roof antenna to the wall plate and your TV.

- Pay TV: Carrying Foxtel or satellite signals.

- NBN (HFC): The Hybrid Fibre Coaxial network uses this cable to deliver high-speed internet from the street to your modem.

- CCTV: Many security cameras use coax to send video footage back to the recorder.

A Job for the Experts

It is important to know that while plugging a lead into your TV is fine, installing fixed coaxial cabling inside your walls is regulated work.

In Australia, any cabling that connects to the telecommunications network or is used for broadcasting services must be installed by a registered licensed cabler. They have the training to terminate the specific F-type or PAL connectors correctly to ensure there is no "signal leakage" which can disrupt the network for your entire neighbourhood.

Get the Right Signal with Schnap Electric

To get a crystal clear picture and fast internet, you need cable that is built to perform. Using cheap, thin cable will only lead to frustration.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of data and visual solutions, including high-quality RG6 Quad Shield coaxial cable rolls, professional compression connectors, and the specialist crimping tools needed to do the job right. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your signal stays strong, clean, and interference-free. For the best in connection gear, trust the range from Schnap Electric.

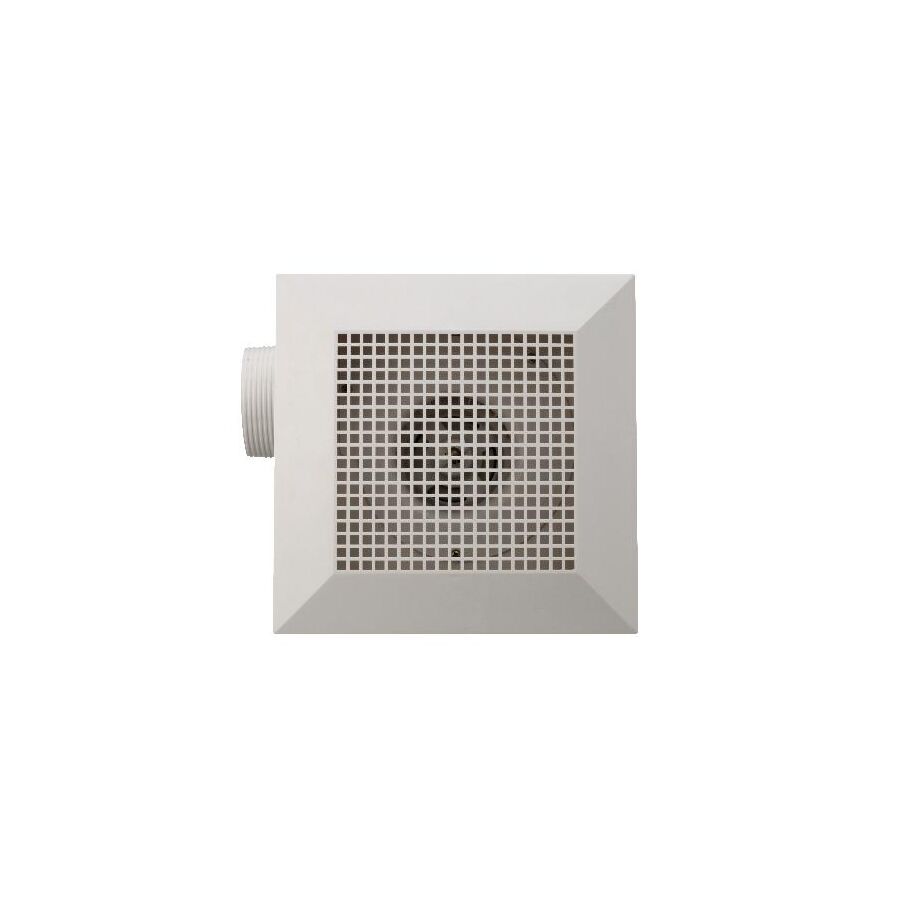

Kitchen Exhaust Fan

G'day! The kitchen is undoubtedly the busiest room in any Aussie house. Whether you are searing a steak for a Friday night dinner or frying up bacon and eggs on a Sunday morning, cooking creates a lot of by-products. Smoke, steam, grease, and lingering odours can quickly turn a pleasant open-plan living area into a foggy, smelly mess. The unsung hero that keeps your home fresh and clean is the humble kitchen exhaust fan.

While we often focus on the oven or the benchtop during a renovation, ventilation is critical. Without adequate extraction, grease particles settle on your cabinets, making them sticky and hard to clean, while moisture from boiling pots can lead to mould growth on the ceiling.

Understanding Your Options

When it comes to moving air in the kitchen, you generally have two main categories to choose from: the dedicated rangehood and the ceiling-mounted exhaust fan.

The Rangehood This is the most common form of kitchen exhaust fan. It sits directly above your cooktop and is designed to capture smoke and steam at the source. They come in various styles, including slide-out (retractable), canopy, and undermount, to suit different cabinetry designs.

Ceiling Exhaust Fans For kitchens without a rangehood, or for older homes that need extra ventilation, a ceiling-mounted exhaust fan is a great solution. These units are similar to bathroom fans but often have higher motor power to deal with the density of cooking fumes. They are particularly useful in large, open-plan kitchens where a rangehood might struggle to clear the entire room.

Ducted vs Recirculating

This is the big decision you need to make regarding where the stale air goes.

- Ducted: This is the gold standard. The fan sucks the air up and pushes it through a ducting pipe to the outside of your house (through the roof or wall). It physically removes the smoke, steam, and smells from the building.

- Recirculating: In some apartments or rentals, ducting to the outside isn't possible. A recirculating kitchen exhaust fan pulls the air through a carbon filter to clean it and then blows it back into the room. While better than nothing, it is less effective at removing heat and moisture.

Noise Levels and Performance

Nobody wants a fan that sounds like a jet engine taking off while they are trying to have a conversation over dinner. When choosing a unit, check the noise level rating (measured in decibels).

You also need to look at the airflow capacity. A large kitchen with a massive gas cooktop needs a powerful motor to be effective. Professional installers often visit a trusted electrical wholesaler to compare the specs of different motors, ensuring they get a unit that moves enough air without being deafeningly loud.

Installation and Safety

Installing a new fan often involves cutting holes in cabinetry or the ceiling and working with 240V mains power. This is strictly regulated work.

In Australia, you must engage a licensed electrician to install any hardwired ventilation equipment. They will ensure the unit is securely mounted and that the ducting is installed correctly to prevent back-drafts. A professional will also ensure the circuit can handle the load, keeping your home safe from electrical faults.

Quality Ventilation from Schnap Electric

To keep your kitchen clean and odour-free, you need extraction gear that is built to last. Cheap fans with plastic motors often rattle and fail after a few years of exposure to heat and grease.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of ventilation solutions, including high-performance kitchen exhaust fan models and heavy-duty motors. Their inventory also includes the essential ducting, grilles, and mounting accessories required for a complete install. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your kitchen remains the fresh, welcoming heart of your home. For ventilation that works as hard as you do, check out the range at Schnap Electric.

Kitchen Exhaust Fan Filter

G'day! We all love a good fry-up on a Sunday morning or searing a steak for dinner, but nobody loves the aftermath. If your kitchen ceiling is starting to feel sticky or the smoke alarm goes off every time you cook, chances are your ventilation system is struggling. The culprit is usually right above your head, hidden in plain sight. It is the kitchen exhaust fan filter, and it is the only thing standing between your expensive fan motor and a mountain of airborne grease.

While it is easy to overlook, this simple component plays a massive role in hygiene and fire safety. A clogged filter restricts airflow, making your fan work harder and louder for less result. Keeping them clean or replacing them when they are knackered is one of the easiest maintenance jobs you can do to keep your Aussie kitchen smelling fresh.

What Does the Filter Actually Do?

When you cook, fat, oil, and moisture become airborne. Your exhaust fan sucks this mixture up. Without a kitchen exhaust fan filter, that grease would coat the fan blades, the motor, and the inside of your ducting.

Over time, this buildup becomes a serious fire hazard. Old, congealed grease is highly flammable. The filter captures these particles before they enter the system. It acts as a trap, allowing the air to pass through while stopping the heavy contaminants.

Mesh vs Carbon: Knowing the Difference

There are generally two types of filters you will encounter in Australian homes, and they require different care.

Aluminium or Stainless Steel Mesh These are the silver grids you see on most ducted rangehoods. They are designed to trap grease physically. The best thing about them is that they are reusable. You can usually pop them in the dishwasher or soak them in hot, soapy water to clean them up. However, if the mesh starts to sag or develops holes, it needs replacing immediately.

Carbon (Charcoal) Filters If your fan recirculates air back into the kitchen rather than venting it outside, you will likely have a carbon filter sitting behind the mesh one. These are designed to neutralise odours. Unlike mesh filters, you cannot clean a carbon filter. Once it is saturated with smells, it must be thrown out and replaced, usually every 6 to 12 months depending on how often you cook.

Sourcing the Right Replacement

Finding a replacement isn't always as simple as grabbing one off the shelf at the supermarket. Rangehoods come in hundreds of different shapes and sizes.

To get the right fit, you often need to measure your existing filter exactly. When looking for replacements, many tradespeople and savvy homeowners visit a dedicated electrical wholesaler to find universal or brand-specific filters that are built to trade standards. Using a flimsy, ill-fitting filter is almost as bad as having no filter at all, as grease will just bypass the edges and get into the motor.

When Cleaning Isn't Enough

Sometimes, no amount of scrubbing will save a filter. If the frame is bent, the locking clips are broken, or the mesh is corroded, it is time for a new one. Running a fan with a damaged filter puts stress on the motor, which can lead to it burning out.

If the motor does burn out, that is not a DIY fix. Replacing a hardwired fan unit involves working with 240V electricity. In Australia, you must engage a licensed electrician to disconnect the old unit and install a new one. They ensure the new fan is balanced, secure, and electrically safe.

Ventilation Solutions from Schnap Electric

To keep your kitchen running smoothly, you need parts that fit perfectly and last the distance.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of ventilation accessories, including high-quality kitchen exhaust fan filter replacements suitable for various models. Their inventory also includes heavy-duty exhaust fans and ducting kits for new installations. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your ventilation system remains efficient, safe, and clean. For a kitchen that stays fresh, check out the range at Schnap Electric.

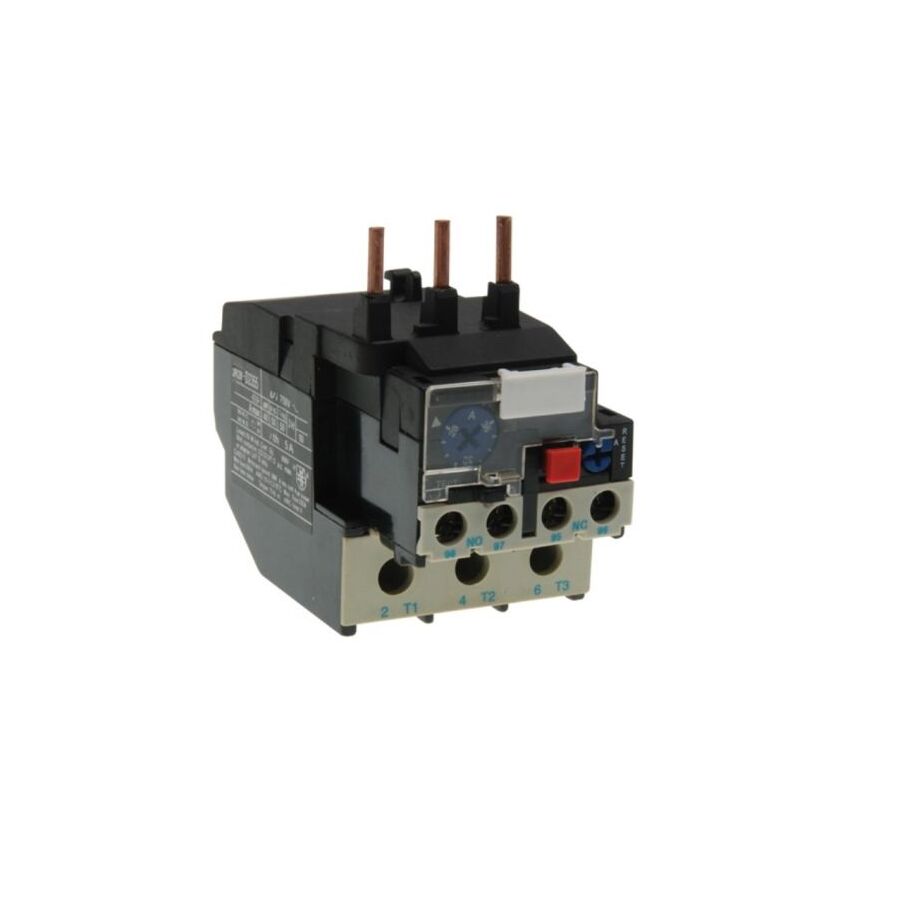

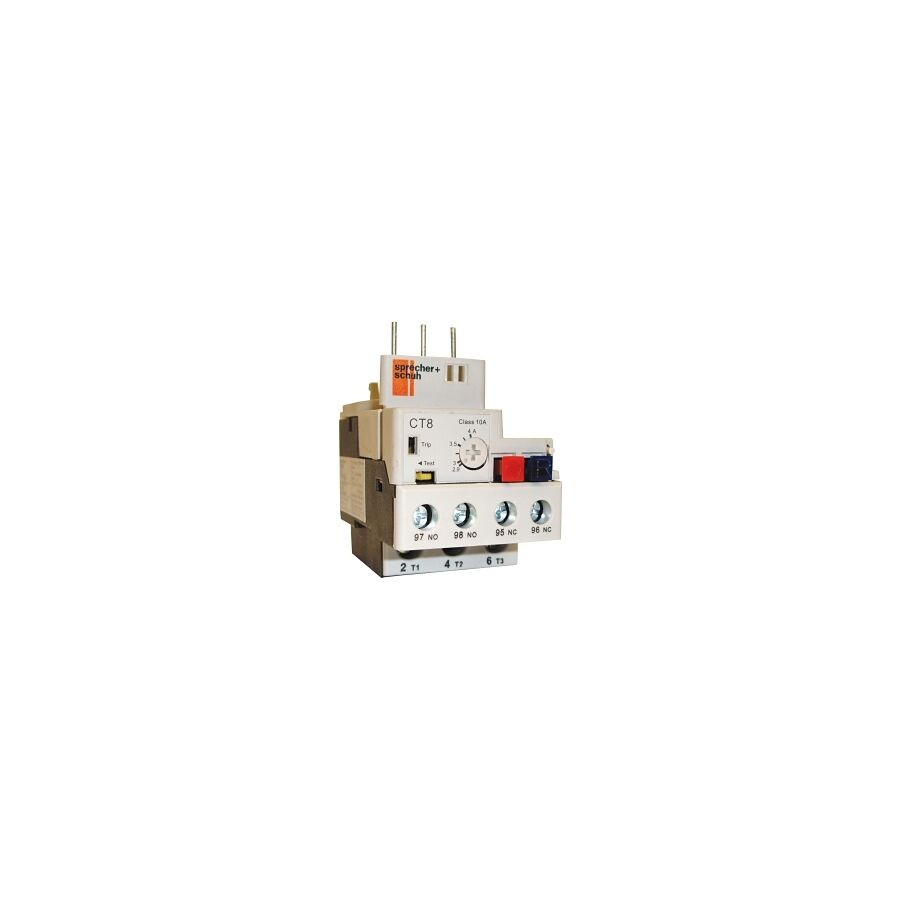

Thermal Overload

G'day! If you run a workshop, a farm, or even just a heavy-duty pool pump, you know that electric motors are the workhorses of the Australian lifestyle. They run our air compressors, conveyor belts, and water pumps day in and day out. However, motors have a weakness. If they are pushed too hard or something jams, they get hot. If they get too hot, the internal windings melt, and your expensive equipment is absolutely cactus.

This is where the thermal overload comes into play. It is a critical piece of safety circuitry designed specifically to protect motors from burning out. While a standard circuit breaker protects the cable from a short circuit, the overload relay protects the machine itself from working itself to death.

How Does a Thermal Overload Relay Work?

It is actually a fairly simple but ingenious bit of engineering. A thermal overload relay contains a small bimetallic strip. The electrical current flowing to the motor passes through a small heating element next to this strip.

If the motor is running normally, the strip stays cool. However, if the motor starts to struggle—perhaps a bearing is seizing up or the pump is blocked—it draws more current. This extra current creates heat. The bimetallic strip heats up and bends. If it bends far enough, it hits a trip mechanism that cuts the power to the contactor, shutting down the motor before permanent damage occurs. It is a fail-safe system that mimics the heating characteristics of the motor.

Why You Cannot Rely on Just a Circuit Breaker

Many people make the mistake of thinking a standard circuit breaker will protect a motor. In most cases, it won't. A circuit breaker is designed to trip instantly if there is a massive surge of current, like a short circuit.

However, a motor burnout usually happens slowly. The motor might be drawing just 10 per cent more power than it should over a few hours. A standard breaker won't notice this slight increase, but that extra heat is slowly destroying the motor insulation. A thermal overload is sensitive enough to detect these small but sustained increases in current and trip the system to save your gear.

Setting It Up Correctly

When you open the control box, you will see a small dial on the face of the relay. This is the amperage setting. For the device to work effectively, this dial must be set to match the Full Load Current (FLC) rating stamped on the motor's compliance plate.

If you set it too high, the motor will burn out before the relay trips. If you set it too low, you will get "nuisance tripping" every time you try to start the machine. It is a fine balance that requires a professional touch.

Sourcing the Right Protection

Because motors come in all shapes and sizes, protection relays do too. When a professional contractor is building a motor starter or replacing a faulty unit, they will typically head to a dedicated electrical wholesaler to find the exact match. They need to ensure the relay is compatible with the contactor and covers the correct amperage range for the specific motor being used. Using a generic part from a hardware store often leads to compatibility issues and unprotected machinery.

Professional Installation is Mandatory

Integrating a protection relay into a motor starter involves working with 240V or 415V mains power. This is not a job for the home handyman.

In Australia, all fixed wiring and work on electrical control panels must be performed by a licensed electrician. They have the testing equipment to measure the actual running current of the motor and fine-tune the thermal overload setting to ensure maximum protection. They will also ensure the reset mode (Manual or Auto) is set correctly for safety, preventing the machine from starting unexpectedly after it cools down.

Heavy-Duty Motor Control from Schnap Electric

If you rely on your machinery to get the job done, you need protection you can trust. A failed relay can result in thousands of dollars in damage to motors and production downtime.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of motor control gear, including high-quality thermal overload relays, contactors, and Direct On Line (DOL) starters. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your pumps, fans, and machinery are protected by robust, reliable components built for Australian conditions. Don't wait for the smoke to come out of your motor; upgrade your protection with Schnap Electric.

Thermal Overload Relay

G'day! Whether you are running a farm irrigation pump, a workshop compressor, or a commercial exhaust fan, the electric motor is the heart of the operation. These pieces of equipment cost a motza to replace, so the last thing you want is for one to burn out because it was pushed too hard. While fuses and circuit breakers protect your cabling, they are often too slow to save a struggling motor. This is why a thermal overload relay is an absolutely non-negotiable piece of kit for any motor control setup.

This device acts as a dedicated bodyguard for your machinery. It monitors the current flowing into the motor and, if things get too hot or heavy, it steps in to cut the power before permanent damage occurs. Understanding how this device works can save you thousands in repairs and downtime.

How Does a Thermal Overload Relay Work?

The concept is simple but incredibly effective. Inside a thermal overload relay, the electrical current passes through a heating element that sits next to a bimetallic strip.

When the motor is running within its normal limits, the strip stays relatively cool. However, if the motor starts to struggle—perhaps the pump is blocked or the bearings are seizing up—it draws more current than it should. This extra current generates heat inside the relay. The bimetallic strip heats up and bends. If it bends far enough, it hits a trip mechanism that opens the control circuit, shutting down the contactor and stopping the motor instantly. It effectively mimics the heating curve of the motor windings, ensuring the power is cut before the insulation melts.

Why You Cannot Just Use a Circuit Breaker

A common misconception is that a standard circuit breaker provides enough protection. It doesn't. A circuit breaker is designed to trip instantly during a massive fault, like a short circuit, to protect the building's wiring.

A motor burnout, however, is usually a slow process caused by a slight "overload." For example, a motor rated for 10 Amps might be drawing 12 Amps because of a mechanical load issue. A standard breaker won't notice this small increase, but that extra current is slowly cooking the motor. A thermal overload relay is sensitive enough to detect this specific condition and trip the system, saving your equipment from becoming completely cactus.

Selecting the Right Unit

Because every motor is different, you cannot just grab any relay off the shelf. The device must be matched to the Full Load Current (FLC) of the motor it is protecting.

Most relays have an adjustable dial on the front. This allows the installer to fine-tune the trip point to match the exact amperage of the motor. If you set it too high, the motor burns out. If you set it too low, the machine trips every time you turn it on. When sourcing these components, a professional will usually head to a specialized electrical wholesaler to find a relay with the correct adjustment range and compatibility with the motor starter (contactor) being used.

Installation and Safety

Integrating motor protection is a complex job. It involves working with control wiring and often 415V three-phase power. This is strictly regulated work in Australia.

You must engage a licensed electrician to install or replace a thermal overload relay. They have the testing equipment to measure the actual running current of the motor and set the relay precisely. They will also ensure the device is wired to stop the motor safely and prevent it from restarting automatically if that presents a safety hazard to operators.

Reliable Motor Control from Schnap Electric

If you rely on your machinery to make a living, you need components that are built to last. A cheap relay that fails to trip can cost you a brand new motor.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of motor control gear, including high-quality thermal overload relay units designed to integrate seamlessly with their range of contactors. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your industrial and commercial equipment is protected by robust, reliable safety mechanisms. Don't risk your motors; upgrade your protection with Schnap Electric.

Analog Timer

G'day! In a world that is becoming increasingly obsessed with Wi-Fi, apps, and touchscreens, there is something to be said for the reliability of mechanical engineering. When it comes to automating your home or business, sometimes the simplest solution is the best. The analog timer remains a staple in Australian switchboards and wall sockets for one very good reason: it works, day in and day out, without fuss.

Whether you are trying to cut down your quarterly electricity bill or ensure your pool stays clean without lifting a finger, understanding the benefits of these mechanical switches is key to running an efficient property.

How Does It Work?

An analog timer operates on a simple 24-hour dial mechanism. Unlike digital versions that require programming through complex menus, an analog unit is tactile and visual. The face of the timer is surrounded by small pins or "tappets."

To set it, you simply push the pins out (or in, depending on the brand) for the hours you want the device to turn on. As the dial rotates with the time of day, the mechanical gears trigger the switch. It is the ultimate "set and forget" technology. If the power goes out, you don't lose your programming; you simply adjust the dial back to the current time once the power is restored.

Why Choose Analog Over Digital?

While digital timers offer precision down to the second, they can be overkill for many applications and often have screens that fade in the harsh Australian sun.

Durability An analog timer is built tough. It handles heat and dust far better than sensitive digital electronics, making it the preferred choice for outdoor enclosures, pool sheds, and industrial environments.

Ease of Use There is no need to find the user manual every time you want to change the schedule. A quick glance at the dial tells you exactly when the power will be on and off. This simplicity reduces user error and frustration.

Best Applications for Mechanical Control

Pool Pumps and Chlorinators This is the classic Aussie use case. A heavy-duty timer ensures your pool filtration runs for the optimum time each day, keeping the water crystal clear without wasting energy.

Security Lighting If you are heading away on holiday, setting a timer to turn interior lights on and off creates the illusion that someone is home. It is a cheap and effective security measure.

Hot Water Systems For those not on a dedicated off-peak ripple signal, a timer can ensure your electric hot water system only heats up during the day when your solar panels are generating free power.

Professional Installation and Sourcing

While plug-in timers are available for lamps, many applications require a DIN rail timer installed directly into your switchboard. This allows you to control entire circuits, such as the hot water or outdoor signage.

It is critical to remember that installing a hardwired analog timer involves working with 240V mains electricity. In Australia, this is strictly a job for a licensed electrician. A professional installer will ensure the device is rated for the electrical load (Amps) it needs to switch. When sourcing these components, a tradesperson will typically head to a reputable electrical wholesaler to find trade-grade timers that feature battery backups and heavy-duty switching gears, ensuring they don't fail prematurely under load.

Reliable Control from Schnap Electric

When you want a component that will stand the test of time, you need to buy from the experts. Flimsy mechanisms can stick or fail, leaving your appliances running 24/7.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of time-switch solutions, including high-quality analog timer modules designed for DIN rail mounting. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your automated systems are robust, compliant, and easy to manage. For control you can count on, trust the range from Schnap Electric.

Floor Box

G'day! Open-plan living and expansive commercial offices are the standard Down Under. We love the feeling of space, but there is one major drawback to having a room without walls: where do you plug everything in? Running extension leads across the carpet is unsightly and, quite frankly, a massive trip hazard. To keep your space looking schmick and safe, the best solution is to install a floor box.

Whether you are fitting out a corporate boardroom or designing a modern living room with a floating sofa, getting power and data to the centre of the room is essential. These clever recessed units allow you to access electricity and internet connections right at your feet, eliminating the dreaded "cable spaghetti" and keeping your floor plan wide open.

Pop-Up vs Flush Mount

When you start looking at your options, you will generally find two distinct styles of floor box available in Australia.

Pop-Up Floor Boxes These are incredibly popular for residential homes and kitchen islands. When not in use, they sit almost flush with the floor. When you need power, you simply press a button, and the sockets "pop up" ready for use. They are sleek, stylish, and often come in finishes like brushed stainless steel or brass to match your decor.

Flush Mount (Recessed) Boxes These are the workhorses of the commercial world. The lid sits flush with the floor, but the sockets are recessed deep inside the box. This allows you to plug in your devices and close the lid (with the cables exiting through a small flap), leaving a flat surface that people can walk over safely. You will often see these under desks or in shopping centres.

Durability is Key

Floors take a beating. They get walked on, cleaned with mops, and bumped by furniture. Consequently, the hardware you install into them needs to be tough.

You cannot use cheap plastic components in a high-traffic area. A high-quality floor box is typically constructed from die-cast metal or heavy-duty stainless steel. It needs to be robust enough to support the weight of a person standing on it without buckling. When a professional installer is sourcing these units, they will visit a dedicated electrical wholesaler to find commercial-grade products that are rated for load-bearing and moisture resistance, ensuring the unit doesn't fail after a few months of use.

Applications Across Australia

The Home Office With more Aussies working from home, having a dedicated power and data point under the desk means you don't have leads trailing back to the wall.

Boardrooms A central box under the conference table is non-negotiable for powering laptops and connecting to projectors without messy cabling.

Retail and Showrooms They allow for powered displays in the middle of the shop floor without creating obstacles for customers.

Installation and Safety

Installing a floor box is not as simple as cutting a hole in the carpet. It involves running cabling through the slab or under a raised floor system. This requires careful planning and precise cutting.

Most importantly, this involves fixed electrical wiring. In Australia, it is illegal to perform this work yourself. You must engage a licensed electrician. They will ensure the box is earthed correctly and that the installation maintains the fire rating and structural integrity of the floor. They also ensure the box has the correct IP rating to prevent water ingress from mopping.

Stylish Solutions from Schnap Electric

If you want to banish the trip hazards and get power exactly where you need it, you need components that look good and stand up to foot traffic.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of floor-mounted power solutions, including stylish pop-up units and heavy-duty recessed floor box models suitable for concrete or timber floors. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your installation is safe, functional, and blends seamlessly with your interior design. For the best in floor power, check out the range at Schnap Electric.

Smart Smoke Alarm

G'day! When it comes to protecting your family and your property, the humble smoke detector has always been the first line of defence. For years, we have relied on standard alarms that simply make a loud noise when they detect smoke. While they are effective if you are home to hear them, they are not much help if you are at work or on holiday. This is where the smart smoke alarm changes the game completely.

By integrating modern Wi-Fi technology with fire safety, these devices offer a level of protection and convenience that traditional alarms simply cannot match. Whether you are tech-savvy or just want the ultimate peace of mind, upgrading to a smart system is one of the best moves you can make for your home.

What Makes an Alarm "Smart"?

A standard alarm is a standalone device. A smart smoke alarm connects to your home internet network and communicates with an app on your smartphone.

This connectivity unlocks a range of life-saving features. The most critical is instant notifications. If smoke is detected while you are out for dinner or at the office, your phone will alert you immediately. This allows you to call emergency services or a neighbour straight away, potentially saving your house from destruction even when you aren't there.

Ending the False Alarm Nightmare

We have all burnt a bit of toast and set off the alarm, leading to a frantic attempt to waft a tea towel at the ceiling while the siren deafens everyone.

With a smart unit, you can usually silence a false alarm directly from your phone app. No more climbing on chairs or trying to hit a button with a broom handle. Furthermore, many of these smart devices run their own diagnostic checks. Instead of waiting for the dreaded low-battery chirp at 3 AM, the app will tell you well in advance if the battery is low or if the sensor needs cleaning.

Interconnection is Key

In many Australian states, particularly Queensland, legislation requires smoke alarms to be interconnected. This means that if one alarm detects smoke, every alarm in the house sounds.

A smart smoke alarm system handles this wirelessly and seamlessly. If a fire starts in the laundry downstairs, the alarm in your bedroom upstairs will sound instantly, giving you the maximum amount of time to evacuate safely. Some advanced systems can even turn on your smart lights to help guide you out of the house in the dark.

Professional Installation and Sourcing

While some battery-powered smart units are DIY-friendly, hardwired 240V alarms offer superior reliability and no battery anxiety. However, installing hardwired alarms involves working with mains electricity.

In Australia, it is illegal to perform your own fixed wiring work. You must engage a licensed electrician to install these units. A professional installer will ensure the alarms are positioned correctly according to the National Construction Code. To guarantee compliance and quality, your installer will typically source these devices from a trusted electrical wholesaler rather than a general electronics store. Trade-quality smart alarms are rigorously tested to meet Australian Standard AS 3786:2014, ensuring they perform when it matters most.

Intelligent Solutions from Schnap Electric

When you are dealing with fire safety, you need technology you can rely on. Glitchy apps or poor connectivity are not an option.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of fire safety solutions, including the latest smart smoke alarm models that feature photoelectric sensors and seamless app integration. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your home is protected by the smartest, safest gear on the market. For protection that keeps you connected, check out the range at Schnap Electric.