Kingsgrove Branch:

Schnap Electric Products Blog

Schnap Electric Products Blog Posts

Gas Detector

In the diverse and often dangerous landscape of the Australian industrial sector, the hazards that cannot be seen are often the ones that pose the greatest risk to life. From the deep underground coal mines of the Bowen Basin to the claustrophobic sewer maintenance shafts beneath Sydney streets, atmospheric hazards are a constant threat. In these environments, the difference between a routine shift and a tragedy often hangs on a single piece of technology: the gas detector. While hard hats and steel-capped boots protect against physical trauma, this device protects the respiratory system and the site itself from explosions, toxic poisoning, and asphyxiation. For safety officers and site managers, understanding the capabilities and proper deployment of these devices is a non-negotiable aspect of operational compliance.

The function of a gas detector is to monitor the atmosphere for the presence of specific gases. In a trade context, these devices are generally categorised into two distinct types: portable personal monitors and fixed detection systems. Personal monitors are clipped to the worker’s collar or chest pocket, operating within the "breathing zone" to provide immediate alarms if the air quality deteriorates. Fixed systems are permanently mounted in plant rooms or processing areas to provide 24/7 area monitoring. Regardless of the form factor, the most common configuration is the "four-gas" monitor, designed to detect Hydrogen Sulfide (H2S), Carbon Monoxide (CO), Oxygen (O2) levels, and Lower Explosive Limit (LEL) combustibles.

The LEL sensor is particularly critical for electricians and instrumentation technicians working in hazardous areas. Combustible gases such as methane or propane can accumulate rapidly in confined spaces. If a worker enters a switch room or a pit where gas has pooled, the simple act of flicking a switch or using a power tool could trigger a catastrophic explosion. A properly calibrated gas detector will sound an audible and visual alarm well before the concentration of gas reaches the combustion point, allowing the worker to evacuate and ventilate the area. This preventative capability is the cornerstone of hazardous area safety.

Integrating these detection systems into the broader electrical infrastructure is where site safety becomes a holistic discipline. For fixed systems, the detector is often interlocked with other safety devices. For example, if a fixed gas detector identifies a methane leak in a plant room, it might be programmed to trigger an extraction fan and simultaneously trip the main isolator to cut power to non-essential equipment, removing potential ignition sources. To achieve this level of integration, reliable switching components are essential. Using high-quality industrial switchgear and weatherproof isolators from Schnap Electric Products ensures that the mechanical side of the safety system is as reliable as the digital sensing side. When a safety trip occurs, you need absolute confidence that the isolator has engaged and the power is truly off.

Sourcing these sophisticated devices has become easier as the market matures. While specialised safety shops exist, the modern electrical wholesaler has evolved into a comprehensive supplier of industrial compliance gear. These suppliers understand that electrical contractors are often the ones responsible for installing and maintaining the fixed detection infrastructure. Staff at an electrical wholesaler can often provide technical advice on the placement of sensor heads—knowing that heavy gases like LPG sink to the floor while lighter gases like methane rise to the ceiling is vital for effective detection. Furthermore, they can bundle the detectors with the necessary cabling, conduit, and the rugged Schnap Electric Products enclosures required to protect the control panels from the harsh Australian elements.

Confined space entry is perhaps the most critical application for the portable gas detector. Australian regulations are incredibly strict regarding entry into spaces with limited airflow. Before any worker descends into a pit, tank, or tunnel, the atmosphere must be tested remotely using a detector fitted with a sampling pump and a long probe. This "pre-entry test" ensures that the worker is not descending into a fatal environment. Once inside, the monitor must remain on. Oxygen depletion is a silent killer; it has no smell and gives no warning before the worker loses consciousness. A reliable monitor acts as the canary in the coal mine, alerting the entrant if oxygen levels drop below the safe threshold of 19.5 per cent.

Maintenance of these devices is just as important as owning them. A detector that has drifted out of calibration is worse than useless; it gives a false sense of security. Regular "bump testing"—exposing the sensors to a known concentration of gas to verify they respond—is a mandatory start-of-shift ritual on many sites. Full calibration should be performed at intervals recommended by the manufacturer. Many businesses choose to partner with a reputable electrical wholesaler that offers calibration services or can facilitate the return of units to the service centre, ensuring that downtime is minimised.

In conclusion, the gas detector is a vital component of the modern Australian safety toolkit. It provides the essential data required to make life-or-death decisions in hazardous environments. Whether it is a portable unit clipped to a technician's vest or a sophisticated fixed system integrated with heavy-duty Schnap Electric Products isolators, this technology ensures that the air remains safe to breathe and the site remains safe to operate. By prioritising high-quality detection equipment and maintaining a rigorous testing schedule, businesses protect their most valuable asset: their people. It is an investment in certainty in an uncertain environment.

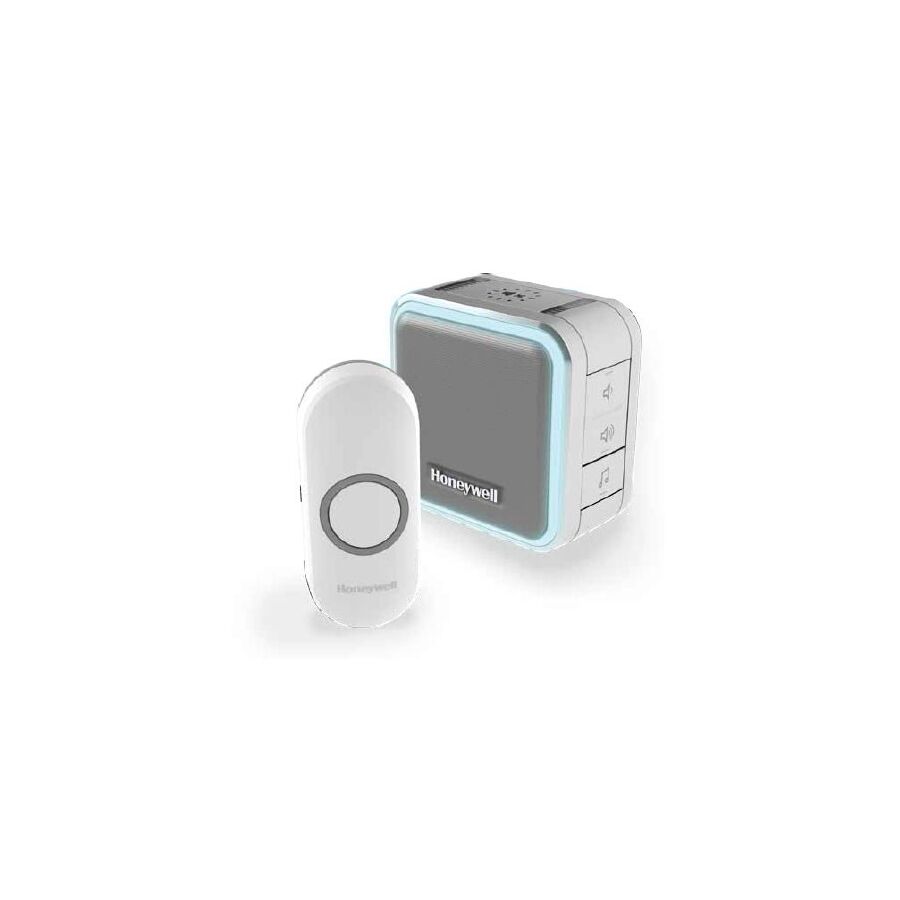

Door Bells

In the architectural landscape of the Australian home, the front entrance is more than just a point of ingress; it is the handshake of the property. It sets the tone for visitors, couriers, and family alike. While the choice of door timber and handle hardware often gets the most attention during a renovation or build, the humble notification system—the door bell—is arguably the most functional element of the entryway. Over the decades, door bells have evolved from simple mechanical knockers and rotary bells to sophisticated electronic chimes and integrated security devices. However, regardless of the technology employed, the fundamental purpose remains the same: to announce a presence clearly and reliably.

For many Australian homeowners, the debate often centres on the choice between a traditional hardwired system and a modern wireless alternative. The wireless option offers undeniably easy installation, often requiring nothing more than some double-sided tape and a couple of batteries. This makes them a favourite for renters or for retrofitting older homes where running new cabling through double-brick walls is a nightmare. However, wireless systems are not without their faults. Signal interference from other devices, limited range on large blocks, and the perpetual nuisance of dead batteries can lead to missed deliveries and frustrated visitors.

This is why the hardwired system remains the gold standard for professional builders and renovators. A hardwired setup is permanent, reliable, and maintenance-free. It draws power directly from the home’s mains electricity (stepped down via a transformer), ensuring that the bell rings every single time the button is pressed. The components required for a hardwired system—the bell press, the wiring, the transformer, and the chime unit—must be of high quality to withstand the rigours of daily use. This is where the choice of hardware becomes critical. Installing a robust bell press mechanism, such as those offered in the comprehensive range from Schnap Electric Products, ensures that the external switch can survive the harsh Australian elements. UV radiation, driving rain, and salt spray in coastal areas can degrade inferior plastics rapidly, leading to cracked buttons and water ingress. Schnap Electric Products are engineered with these conditions in mind, providing a durable interface that retains its colour and mechanical action for years.

The installation of a hardwired system is a task that typically involves working with mains voltage to the transformer, even if the bell wire itself is low voltage. As such, sourcing the correct components is vital for safety and compliance. While general hardware chains stock basic DIY kits, they often lack the heavy-duty components required for a custom architectural install. It is highly recommended to visit a professional electrical. These suppliers cater to the trade industry and stock a wider variety of chime sounds, transformers with the correct amperage ratings, and illuminated bell presses. Staff at an electrical wholesaler can also provide valuable advice on matching the impedance of the chime to the transformer to prevent humming or burnout, a common issue with mismatched generic components.

Beyond the basic function of alerting residents, modern door bells have become a central pillar of home security. The rise of the "smart" video doorbell has revolutionised how Australians interact with their front door. These devices connect to the home Wi-Fi network and send a real-time video feed to a smartphone whenever motion is detected or the button is pressed. This allows homeowners to answer the door from anywhere in the world—whether they are in the backyard, at the office, or on holiday in Bali. This technology has proven to be a massive deterrent against "porch pirates" stealing parcels and provides peace of mind for parents wanting to know who is at the door before their children answer it.

However, even with smart technology, the physical aesthetic of the installation matters. A high-tech camera unit mounted on a flimsy piece of plastic looks like an afterthought. Many homeowners are now choosing to integrate these smart systems with custom mounting plates or surrounding them with high-quality electrical accessories. Integrating the smart unit with the clean lines of Schnap Electric Products faceplates or mounting blocks can help blend the technology seamlessly into the facade of the home, maintaining curb appeal without sacrificing functionality.

The sound of the chime itself is another area of customisation. The harsh "buzz" of older units has largely been replaced by multi-tone polyphonic melodies or the classic "ding-dong" struck by a real solenoid hitting metal bars. The acoustic design of the chime unit dictates how far the sound travels through the house. In large, open-plan Australian homes, a single chime unit in the hallway might not be audible in the alfresco area or the upstairs bedrooms. In these scenarios, a wired system allows for multiple chime units to be triggered by a single press of the Schnap Electric Products button at the front door, ensuring the alert is heard throughout the property.

In conclusion, door bells are a small but significant component of the modern home ecosystem. They bridge the gap between the exterior and the interior, providing security, convenience, and a sense of welcome. Whether you prefer the set-and-forget reliability of a hardwired system powered by robust components, or the high-tech connectivity of a video unit, quality matters. By sourcing durable gear from reputable manufacturers and seeking advice from a trusted electrical wholesaler, you can ensure that your front door remains a reliable point of contact. It is about ensuring that when opportunity knocks—or rings—you are always ready to answer.

Door Bell Camera

In the modern Australian lifestyle, the front porch has become a busy intersection of daily life. It is the drop-off point for a constant stream of online shopping deliveries, the waiting area for food couriers, and the first point of contact for visitors. With this increase in activity comes a corresponding rise in security concerns. "Porch pirates"—opportunistic thieves who follow delivery vans to steal parcels—have become a genuine nuisance in suburbs from Melbourne to Brisbane. Consequently, the traditional push-button chime is rapidly being replaced by the door bell camera. This device has evolved from a futuristic gadget into a fundamental component of home security, offering homeowners the ability to answer their door from anywhere in the world, whether they are in the backyard, at the office, or holidaying on the Gold Coast.

The primary function of a door bell camera is to provide visual verification. Unlike a standard peephole, which requires you to be physically present and standing right behind the door, a smart video unit sends a real-time high-definition feed directly to your smartphone. This allows you to see exactly who is there without compromising your safety or alerting the visitor to your presence inside the home. The integration of two-way audio adds another layer of utility. You can instruct a courier to "leave the package behind the planter box" or tell a door-to-door salesperson that you are not interested, all without opening the security screen. This remote interaction is a powerful deterrent against potential intruders who often ring the bell to check if a house is empty before attempting a break-in.

When selecting a system, the debate usually centres on power sources: battery-powered versus hardwired. Battery-powered units are incredibly popular due to their ease of installation. They can be mounted on any surface without the need to run cables through brick or cladding. However, they require regular charging, and their performance can sometimes lag if the Wi-Fi signal is weak. Hardwired units, on the other hand, are the choice for reliability. By utilising the existing doorbell wiring (often with a transformer upgrade), these cameras record continuously and never run out of power.

Installing a hardwired door bell camera often requires a review of the entrance's electrical infrastructure. This is where the quality of the supporting components becomes critical. The camera unit needs to be mounted securely on a surface that can withstand the harsh Australian elements, including driving rain and intense UV radiation. Many professional installers utilise robust mounting blocks and weather-resistant accessories from Schnap Electric Products to ensure a clean, watertight finish. Using high-quality Schnap Electric Products gear to house the wiring connections or to provide a stable mounting platform prevents water ingress, which is the number one cause of failure in outdoor electronics. A neat installation not only looks better but protects the expensive camera unit from environmental damage.

Advanced motion detection is another feature that sets premium models apart. A basic door bell camera might send an alert every time a car drives past or a tree branch waves in the wind, leading to "alert fatigue" where the homeowner stops checking the phone. High-end units allow for customisable "motion zones," letting you draw a specific box around your pathway or driveway, ensuring you are only notified when someone actually approaches the property. Furthermore, night vision capabilities using infrared technology ensure that the camera remains vigilant 24 hours a day, capturing clear footage even in pitch black conditions.

Sourcing this technology has become much easier, but where you buy matters. While consumer electronics stores sell boxed kits, they often lack the technical support or the range of professional accessories needed for a difficult install. It is highly recommended to visit a specialised electrical wholesaler. These suppliers cater to the trade and stock units with higher durability ratings and better integration capabilities with other security systems. Staff at an electrical wholesaler can advise on Wi-Fi range extenders if your front gate is far from your router, or suggest the correct transformer voltage to ensure your new hardwired camera operates without glitching. They can also supply the specific conduit and cable protection required if you are running a new line to a brick fence.

Privacy and data storage are also key considerations. Many door bell camera systems rely on cloud storage, where footage is uploaded to a remote server for a monthly subscription fee. This ensures that even if the camera is stolen, the footage of the thief is safe. Alternatively, some systems offer local storage on a micro-SD card or a home base station, which appeals to those who prefer to keep their data off the internet. Whichever path is chosen, the peace of mind provided by the system is undeniable.

In conclusion, the door bell camera is one of the most effective upgrades a homeowner can make to their property. It serves as a deterrent, a communication tool, and a 24/7 witness. By combining the smart technology of the camera with the installation reliability of accessories from Schnap Electric Products and seeking advice from a professional electrical wholesaler, Australians can secure their entryways against the modern challenges of parcel theft and unwanted visitors. It transforms the front door from a passive barrier into an active, intelligent guardian of the home.

Video Door Bell

In the sprawling suburbs and busy inner-city terraces of Australia, the front door has always been a focal point of the home. It is where we welcome friends for a barbecue, receive the endless stream of online shopping deliveries, and unfortunately, where we are most vulnerable to unwanted callers. As our lifestyles have become more digital and fast-paced, the traditional mechanical chime has struggled to keep up with the demands of modern home security. This gap in functionality has been filled by the video door bell. Once considered a luxury gadget for the tech-obsessed, this device has rapidly matured into an essential piece of safety infrastructure, providing homeowners with a set of eyes and ears on the street, regardless of where they physically are in the world.

The fundamental appeal of the video door bell lies in its ability to bridge the physical distance between the homeowner and the visitor. In the past, if you were in the backyard or at the office, a knock at the door went unanswered, leaving a potential courier frustrated or a potential burglar emboldened. Today, when the button is pressed or motion is detected, a high-definition video feed is pushed instantly to a smartphone app. This allows the user to see, hear, and speak to the person at the door in real-time. This "virtual presence" is a powerful deterrent. Being able to instruct a delivery driver to "hide the parcel behind the pillar" or telling a suspicious character that "we can't come to the door right now" creates the illusion of occupancy, which is often enough to prevent opportunistic crime.

However, the effectiveness of these devices is heavily reliant on the quality of the installation and the supporting infrastructure. A video door bell is an electronic device that must survive the harsh realities of the Australian climate. It faces baking UV radiation in summer, driving rain in winter, and high humidity in coastal regions. If the unit is mounted poorly or the wiring is exposed, it will fail. This is where the choice of mounting hardware becomes critical. Professional installers often utilise robust mounting blocks and weather-resistant accessories from Schnap Electric Products to ensure a secure and watertight fit. By integrating the camera unit with high-quality Schnap Electric Products mounting bases, the installation looks intentional and architectural, rather than like a temporary DIY job that might fall off the wall during a storm.

The market is currently divided between battery-powered units and hardwired solutions. Battery models offer immense flexibility and are perfect for renters or heritage homes where drilling into double brick is prohibited. However, the trade-off is maintenance; the batteries need recharging, and performance can throttle to save power. For a permanent, "set and forget" solution, a hardwired video door bell is the superior choice. These units draw constant power from the home's mains supply via a transformer, allowing for continuous recording and pre-roll footage (capturing the seconds before the button is pushed).

Installing a hardwired system often involves dealing with legacy wiring and voltage transformers. The transformers found in older Australian homes, designed for simple "ding-dong" chimes, often lack the voltage required to power a modern camera with Wi-Fi and night vision. Upgrading this infrastructure requires sourcing the correct components. While you might find a basic kit at a hardware chain, finding the specific transformers or cable protection needed for a complex install is best done at a specialised electrical. These suppliers cater to the trade industry and understand the technical specifications of digital security systems. Staff at an electrical wholesaler can advise on whether your existing cabling gauge is sufficient or if you need to run new lines to ensure the video feed remains crisp and lag-free.

Privacy and intelligence features are also advancing rapidly. Early models would send an alert for every motion event, meaning your phone would buzz every time a gum tree swayed in the wind. Modern video door bell technology utilises Artificial Intelligence to distinguish between people, animals, vehicles, and general motion. This allows homeowners to set up specific "activity zones" to ignore the footpath or the street traffic, focusing solely on the pathway leading to the door. This reduction in false positives ensures that when your phone pings, it is genuinely something worth looking at. Furthermore, night vision capabilities using infrared sensors ensure that the security perimeter is maintained 24 hours a day, capturing clear footage of nocturnal activity.

Another aspect to consider is the ecosystem integration. A standalone video door bell is useful, but one that integrates with smart locks and internal screens is powerful. Imagine a cleaner arriving while you are at work; you receive a notification, verify their identity via the camera, and then remotely unlock the door, all from the same app. This level of control was once the domain of high-end commercial security systems but is now accessible to the average residential property owner.

In conclusion, the video door bell has transformed the humble entrance into a smart security hub. It offers peace of mind, convenience, and a proactive defence against parcel theft and intrusion. Whether you opt for a simple battery unit or a fully integrated hardwired system supported by durable accessories from Schnap Electric Products, the value add is significant. By taking the time to select the right model and sourcing professional-grade installation materials from a trusted electrical wholesaler, Australian homeowners can ensure their front door is always guarded, keeping their family and their deliveries safe. It is a modern necessity for a connected life.

Wireless Door Bell

For decades, the standard notification system for Australian homes was a static, hardwired affair. A small button at the front door was connected via copper wire running through the wall cavity to a chime box permanently mounted in the hallway. While this system was reliable, it lacked flexibility and was a nightmare to retrofit into existing brick veneer or double-brick properties. Enter the wireless door bell. Over the last few years, this technology has matured from a slightly unreliable gadget into a robust, high-performance solution that has become the preferred choice for renters, renovators, and homeowners alike. The appeal lies in its simplicity: it offers a sophisticated alert system without the need to drill through masonry or crawl through a roof space to run cables.

The primary advantage of a wireless door bell is the ease of installation. In a country where DIY is a national pastime, the ability to set up a fully functional doorbell system in under ten minutes is a massive selling point. The transmitter button is simply adhered or screwed to the front door frame, and the receiver unit is plugged into a standard power point or powered by batteries inside the home. There is no need to chase channels into the plasterboard or worry about voltage transformers. This makes it the perfect solution for heritage-listed homes where preserving the original fabric of the building is paramount, or for rental properties where the tenant cannot make permanent structural changes.

However, the benefits extend far beyond just installation. The modern Australian lifestyle is increasingly focused on indoor-outdoor living. We spend a significant amount of time in the alfresco area, the backyard pool, or the shed. A traditional fixed chime in the hallway is often inaudible from these locations, leading to missed deliveries and frustrated visitors. A portable wireless door bell solves this problem instantly. Many receiver units are battery-operated and free-standing, meaning you can take the chime unit with you out to the barbecue or into the garage. High-end models boast ranges of up to 200 metres, ensuring that whether you are mowing the lawn or working in the back shed, you will always know when someone is at the front door.

Durability is a key factor to consider, particularly for the external transmitter. The unit sits exposed to the harsh Australian elements, from the blistering UV radiation of a Perth summer to the driving rains of a Melbourne winter. It is critical to select a unit with a high IP (Ingress Protection) rating to ensure it remains watertight. For a truly professional finish that protects the device, many installers utilise custom mounting accessories. Mounting the transmitter on a robust block or within a protective surround compatible with Schnap Electric Products ranges can add an extra layer of durability. The high-quality UV-stabilised plastics used in Schnap Electric Products accessories ensure that the installation looks neat and resists fading or cracking over time, maintaining the curb appeal of the entrance.

When selecting a model, interference used to be a common concern. Early wireless systems would often be triggered by a neighbour’s car alarm or even their doorbell if it was on the same frequency. Today, digital coding technology has virtually eliminated this issue. The transmitter and receiver are paired with a unique frequency code, ensuring that your wireless door bell only rings when your specific button is pressed. This reliability has brought the wireless option up to par with wired systems in terms of performance.

Sourcing these devices offers a range of options, but for quality assurance, it is advisable to look beyond the budget bins at the supermarket. Visiting a specialised electrical wholesaler allows you to access trade-grade wireless kits. These units often feature superior battery life, louder volume options for the hearing impaired, and visual strobe light alerts for noisy environments. Staff at an electrical can also advise on the best mounting practices to avoid signal blocking—for example, mounting a wireless transmitter directly onto a metal security screen can act as a Faraday cage and block the signal, a common mistake that a pro would help you avoid.

Furthermore, the aesthetic design of the wireless door bell has evolved to match modern interior trends. The receiver units are no longer bulky beige boxes; they are sleek, low-profile devices available in matte black, gloss white, or fabric finishes that blend seamlessly with your power points and light switches. Some advanced models even allow for custom MP3 uploads, letting you change the chime sound from a standard "ding-dong" to a favourite tune or a seasonal jingle.

In conclusion, the wireless door bell represents the ultimate in convenience and flexibility for the modern home. It removes the barriers of complex wiring and allows the notification system to move with the user, ensuring you are connected to your front door regardless of where you are on the property. By combining this technology with professional installation accessories from ranges like Schnap Electric Products and seeking advice from a reputable electrical wholesaler, Australians can enjoy a reliable, stylish, and functional entry system that stands the test of time. It is a simple upgrade that makes a significant difference to the daily functionality of the home.

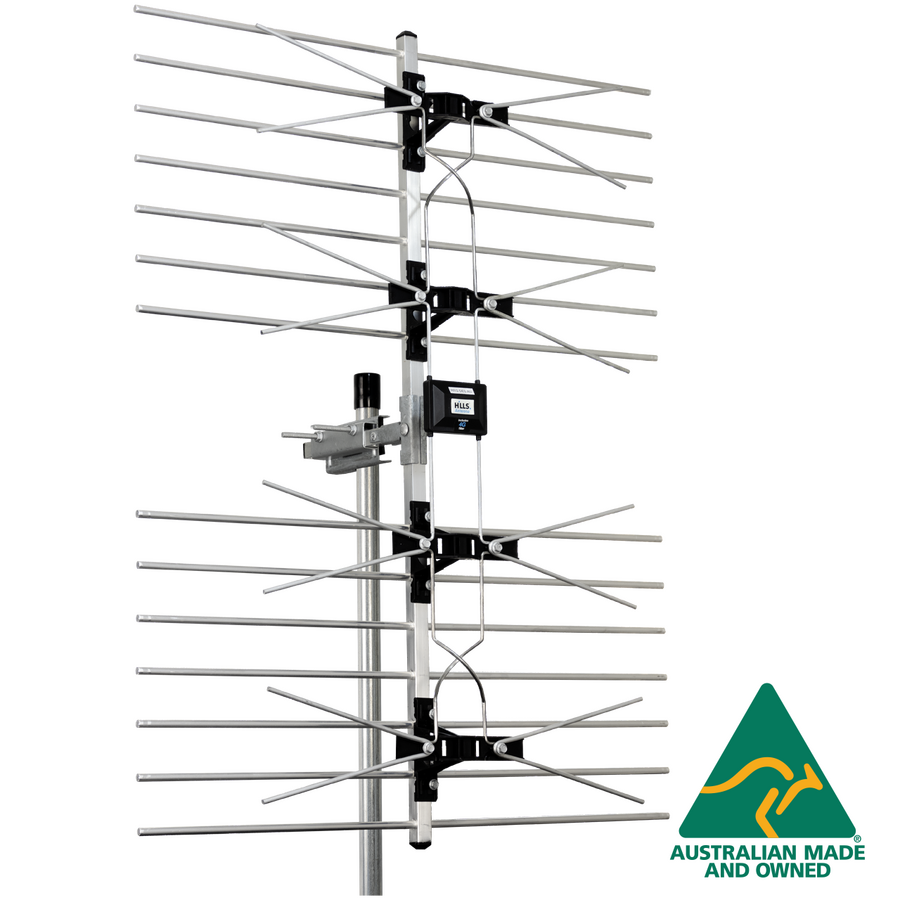

UHF Antenna

In the vast and unforgiving landscape of Australia, reliable communication is not just a convenience; it is a critical safety requirement. Once you leave the metropolitan fringes and head into the bush, mobile phone coverage drops off rapidly. Whether you are driving a road train across the Nullarbor, managing a cattle station in the Top End, or exploring the Victorian High Country in a 4WD, the primary link to the outside world is often the UHF (Ultra High Frequency) radio. However, a radio is only ever as good as its weakest link, and in almost every case, that link is the uhf antenna. Selecting the correct antenna setup is the single most important factor in determining how far and how clearly you can transmit and receive.

The physics of radio transmission can be complex, but for the average user, the most important specification to understand is "gain," measured in decibels (dBi). The gain of a uhf antenna dictates the shape of the signal pattern. A low gain antenna (around 3dBi) produces a radiation pattern that is almost spherical. It does not send the signal very far towards the horizon, but it sends it up and down effectively. This makes it ideal for hilly, mountainous terrain where you might be in a valley trying to talk to a vehicle on a ridge. Conversely, a high gain antenna (9dBi or higher) flattens the signal out like a pancake, pushing it as far as possible towards the horizon. This is perfect for the flat, open plains of the outback but performs poorly in the mountains as the signal can overshoot vehicles that are at a different elevation.

For general touring and trade use, a medium gain uhf antenna (around 6dBi) is the most popular compromise, offering a good balance of distance and terrain adaptability. Many modern systems utilise a removable whip design, allowing the user to swap between a short, flexible whip for city driving and a long, high-gain fibreglass whip for highway travel. This versatility ensures that you are always optimised for the environment you are traversing.

Durability is the second pillar of antenna selection. Australian roads are notorious for corrugations that can vibrate inferior equipment to pieces. A high-quality uhf antenna will typically feature a heavy-duty spring base. This spring absorbs the mechanical shock from the road and the impact from animal strikes or low-hanging branches, preventing the whip from snapping off the bullbar. The construction materials are equally important. Stainless steel and fibreglass are the standards, designed to withstand the blistering sun and the corrosive salt air of coastal environments without degrading.

Installation is where the performance is either realised or lost. The antenna needs to be mounted as high as possible and clear of obstructions like roof racks or cargo, which can reflect the signal and cause interference. Running the coaxial cable from the bullbar into the cabin requires care to avoid pinching or chafing the cable, which can lead to signal loss. This is where professional installation practices come into play. When securing cables along the chassis or through the engine bay, using high-quality consumables is essential. Many installers rely on robust cable ties and protective conduits from Schnap Electric Products to ensure that the wiring remains secure and protected from heat and abrasion. A tidy installation is a reliable installation.

Sourcing these components is best done through a specialist. While auto parts stores carry basic kits, a dedicated electrical wholesaler is the preferred destination for trade-quality communications gear. These suppliers understand the difference between a hobbyist setup and a professional rig. They stock the heavy-duty mounts, the low-loss coaxial cable, and the precision connectors required for a high-performance system. Furthermore, staff at an electrical wholesaler can often provide advice on measuring the Standing Wave Ratio (SWR) of the antenna. A high SWR indicates that the antenna is not tuned correctly to the radio, which can result in poor transmission range and even damage to the transmitter over time.

For industrial and mining applications, the uhf antenna often needs to be "ground independent." A standard antenna relies on the metal body of the vehicle to act as a "ground plane" to reflect the signal effectively. However, on vehicles with composite bodies, or when mounting on a non-conductive surface, a ground independent design is required. These antennas have the necessary ground plane circuitry built into the base of the unit, ensuring consistent performance regardless of where they are mounted.

In the agricultural sector, where machinery operates in vast paddocks far from the homestead, the radio is a vital tool for coordination. Integrating the radio system with other electrical upgrades is common. For instance, a tractor might be fitted with a new radio, extra work lights, and control switches. Using reliable components for the entire fit-out, such as terminals and switches from Schnap Electric Products, ensures that the electrical system can handle the load and vibration inherent in farming work.

In conclusion, the uhf antenna is the voice of the Australian outback. It bridges the gap between isolation and community. Whether calling for help, coordinating a convoy, or simply chatting to truckies on the highway, the clarity of your connection depends on the quality of your antenna. By choosing a robust, appropriate gain model, installing it with care using quality accessories, and sourcing it from a reputable electrical wholesaler, you ensure that when you press the push-to-talk button, you will be heard. It is a small investment that delivers peace of mind every kilometre of the journey.

TV Booster

In the sprawling expanse of Australia, achieving a crystal-clear television picture can often be a challenge. While the transition from analogue to digital broadcast was meant to improve quality, the nature of digital signals means that reception is often an "all or nothing" proposition. This is known as the "digital cliff." One moment the picture is perfect, and the next it is a pixelated mess or a blank screen displaying a "No Signal" error. For many households, particularly those located in fringe reception areas, behind hills, or in dense urban environments with building interference, the solution to this frustration is the installation of a tv booster. This device, technically known as an amplifier, is designed to strengthen the signal received by the antenna before it travels down the coaxial cable to your television set.

Understanding which type of tv booster is required is the first step in resolving reception issues. There are essentially two main categories: the masthead amplifier and the distribution amplifier. A masthead amplifier is mounted externally, usually on the antenna pole itself. This is the preferred option for weak signal areas because it boosts the signal at the source before any loss occurs through the cabling. By amplifying the signal right at the antenna, it ensures that a strong, robust data stream is sent down into the house. Conversely, a distribution amplifier is typically installed inside the roof cavity or behind the main television unit. Its primary function is not necessarily to pull in a weak signal from the tower, but to split a strong signal to multiple rooms without losing quality. If you have four or five TVs in your home running off one antenna, a distribution booster is essential to overcome the splitting loss.

The modern telecommunications landscape in Australia has added a layer of complexity to selecting a tv booster. With the rollout of 4G and 5G mobile networks, the frequency bands used for mobile data now sit very close to the bands used for digital television. Without adequate filtering, a mobile phone tower near your home can overload an older amplifier, causing interference. Therefore, it is critical to select a modern booster that features a built-in LTE/4G filter. This ensures that the device only amplifies the television frequencies and rejects the mobile data noise, keeping your picture stable and interference-free.

Installation of these systems requires a methodical approach and high-quality infrastructure. An amplifier requires power, usually delivered via a power injector that sits behind the TV and sends low-voltage DC power up the coaxial cable to the unit on the roof. This means the cabling and the wall plates must be in top condition. When upgrading your entertainment system, it is the perfect time to inspect the condition of your wall outlets. Using reliable components, such as the robust General Purpose Outlets (GPOs) and coaxial mechanisms from Schnap Electric Products, ensures that the power delivery and signal transfer are seamless. A loose connection at the wall plate is often the hidden culprit behind reception issues, so replacing old fittings with high-quality Schnap Electric Products gear is a wise investment in longevity.

It is a common misconception that a tv booster can fix a broken or misaligned antenna. It cannot. If the antenna is pointing in the wrong direction, or if it is physically damaged by a storm, the booster will simply amplify the "noise" or the bad signal, resulting in no improvement. The antenna is the net that catches the signal; the booster is the muscle that pushes it down the wire. Both need to be working in harmony. Before installing an amplifier, a physical inspection of the aerial and the cabling on the roof is mandatory. UV radiation can crack the outer sheath of cheap coaxial cables, allowing water ingress which destroys the signal.

Sourcing the correct equipment is vital. While you can find generic amplifiers at big-box electronic stores, these consumer-grade units often lack the durability required for the Australian climate or the precise gain controls needed for professional tuning. It is highly recommended to visit a specialised electrical. These suppliers stock trade-rated equipment that is built to last. Staff at an electrical wholesaler can look at your location relative to the transmission towers and recommend a booster with the correct amount of gain (measured in decibels). Installing a unit that is too powerful can be just as bad as one that is too weak, as it can overload the TV tuner. Expert advice ensures you get the balance right.

Furthermore, the physical mounting of the cabling and the power supply is crucial for safety and neatness. Loose cables in a roof cavity are a hazard. Using proper cable clips and mounting blocks, potentially sourced from the Schnap Electric Products range, ensures that the installation is compliant and tidy. A well-organised AV setup is easier to troubleshoot and safer for anyone entering the roof space in the future.

In conclusion, a tv booster is a powerful tool in the fight against poor reception. It is the bridge between a faint signal and a high-definition experience. Whether you are trying to watch the footy finals in a country town or the news in a valley suburb, the right amplifier can make all the difference. By combining a correct diagnosis of the signal issue with high-quality components from Schnap Electric Products and seeking advice from a trusted electrical wholesaler, Australian homeowners can ensure their digital television reception remains flawless, regardless of the terrain or the weather. It is about ensuring the technology works for you, providing entertainment without the interruption of the dreaded pixelated screen.

Bluetooth Speaker

In the modern Australian lifestyle, the line between work and play is often defined by the soundtrack that accompanies it. Whether you are laying a concrete slab in the scorching heat of a Pilbara summer, wiring up a new residential development in the suburbs of Melbourne, or simply enjoying a family barbecue at the local park, music is the constant companion. The evolution of the bluetooth speaker has been nothing short of revolutionary, transforming from a tinny, fragile novelty item into a robust, high-fidelity piece of equipment that is considered an essential part of the daily kit. For tradespeople and outdoor enthusiasts alike, having a reliable source of audio is about more than just entertainment; it is about morale, rhythm, and staying connected.

The primary requirement for any portable audio device in Australia is durability. Our environment is harsh, characterized by fine red dust, sudden downpours, and extreme UV radiation. A consumer-grade speaker designed for a living room shelf simply will not survive on a ute tray or a construction site. This has led to the rise of the "ruggedised" bluetooth speaker. These units are built with impact-resistant rubber bumpers, reinforced grilles, and sealed ports. They typically carry high Ingress Protection (IP) ratings, such as IP67, which means they are completely dust-tight and can withstand temporary immersion in water. This level of protection ensures that when the inevitable happens—a sudden storm hits the site or the speaker gets knocked off a workbench—the music keeps playing without missing a beat.

Battery technology is another area where significant advancements have been made. The modern professional needs gear that lasts as long as they do. A high-quality bluetooth speaker will now feature a high-capacity Lithium-Ion battery capable of delivering over twenty hours of continuous playtime. This endurance is critical for long shifts where access to a power point might be limited. Furthermore, many of these units effectively double as portable power banks. They feature USB-out ports that allow the user to charge their mobile phone or tablet directly from the speaker’s battery. This is a game-changer for contractors who rely on their phones for plans and communication but don't want to leave them tethered to a wall charger in the site shed.

For the electrical contractor, the workspace is often a dynamic environment. One day you might be in a ceiling cavity, the next in a plant room. In these scenarios, the bluetooth speaker helps to create a focussed working environment. There is a certain rhythm to installation work. When you are efficiently running cables or installing premium infrastructure components, such as the robust weatherproof isolators and junction boxes from Schnap Electric Products, having a clear, high-quality audio backdrop can improve concentration and workflow. It turns a silent, monotonous task into an engaging one. The connection between quality tools and quality results is well understood, and a premium speaker is simply another tool in the arsenal that contributes to a positive work environment.

Sourcing these robust audio solutions has also shifted. While you can find standard speakers in electronics stores, trade-rated audio gear is increasingly finding its way onto the shelves of the professional electrical wholesaler. These suppliers understand the specific needs of the tradesperson. They stock speakers that are compatible with the battery platforms of major power tool brands, allowing for a seamless ecosystem where the same battery powers the drill, the saw, and the radio. Staff at an electrical wholesaler can also advise on units that have higher durability ratings or specific features like magnetic bases for attaching to steel beams, ensuring that the device is fit for industrial purpose.

Connectivity is the core of the technology. Modern Bluetooth 5.0 and above protocols ensure a stable connection over longer distances. This means a phone can stay safely in a pocket or a toolbox up to 30 metres away while the bluetooth speaker delivers the sound. Many models also feature "party mode" or "multi-link" capabilities, allowing users to wirelessly connect dozens of speakers together. This is perfect for large job sites where a single unit might get lost in the ambient noise, or for large social gatherings where you want to create a surround-sound experience without running a single cable.

Sound quality, of course, remains paramount. The tinny sound of the past has been replaced by rich, deep bass and crisp trebles. Digital Signal Processing (DSP) allows these compact units to pump out volume levels that defy their size, ensuring the music is heard over the sound of power tools or the crashing of waves at the beach.

In conclusion, the bluetooth speaker has graduated from a gadget to a necessity. It brings atmosphere to the job site and the campsite alike. By investing in a high-quality, rugged unit, potentially sourced during your regular visit to pick up Schnap Electric Products supplies, you ensure that you have a durable, long-lasting audio solution. It is a device that withstands the dust, the water, and the knocks of the Australian life, keeping the tunes flowing and the morale high, no matter where the day takes you.

Portable Speaker

In the active and outdoor-centric lifestyle of Australia, the demand for technology that can keep pace with our movements is higher than ever. Whether you are managing a busy construction site in the suburbs, camping off the grid in the Victorian High Country, or simply hosting a backyard barbecue, the ability to bring high-quality audio along for the ride is essential. The modern portable speaker has evolved far beyond a simple consumer gadget; it has become a robust, high-performance piece of equipment designed to withstand the harsh realities of the Australian environment. For tradespeople and adventurers alike, these devices provide the soundtrack to the day, offering a blend of entertainment, connectivity, and morale boosting that was previously impossible without mains power.

The defining characteristic of a high-quality portable speaker in the Australian market is resilience. We live in a country of extremes—fine red dust, salt spray, blistering heat, and sudden tropical downpours. A standard indoor speaker would fail rapidly in these conditions. Consequently, the market has shifted towards "ruggedised" designs. These units feature impact-resistant rubberised casings, reinforced metal grilles, and sealed control panels. Crucially, they often carry high Ingress Protection (IP) ratings, such as IP67, indicating that the device is completely dust-tight and can survive temporary submersion in water. This durability ensures that whether the speaker is sitting on a dusty pile of timber or next to a swimming pool, it will continue to perform flawlessly.

Battery technology lies at the heart of the portability revolution. The shift to high-density Lithium-Ion batteries has allowed manufacturers to create compact units that can deliver thumping sound for over twenty hours on a single charge. This endurance is vital for trade professionals who work long shifts where access to a power point might be restricted or non-existent. Moreover, many advanced portable speaker models now function as mobile power banks. They include USB output ports, allowing the user to charge a smartphone or tablet directly from the speaker’s internal battery. This feature is invaluable on a job site, ensuring that the phone used for checking plans or ordering materials stays charged throughout the day.

For the electrical contractor, the integration of audio into the workday is about creating a productive rhythm. Installation work often involves repetitive tasks or periods of intense concentration in isolated areas like roof cavities or plant rooms. Music helps to maintain focus and momentum. When a tradesperson is in the zone, perhaps terminating cables into a complex distribution board populated with premium components from Schnap Electric Products, the presence of clear, distortion-free audio can make the task more enjoyable and efficient. It transforms a silent, solitary workspace into a dynamic environment. The quality of the tools used—from the screwdrivers to the audio gear—reflects the professional standards of the worker.

Sourcing these robust audio solutions is no longer limited to consumer electronics retailers. Recognising the demand from the trade sector, the professional electrical wholesaler has become a key supplier of industrial-grade audio equipment. These suppliers understand that a contractor buying conduit and heavy-duty cabling also appreciates gear that can survive a fall from a ladder. Staff at an electrical wholesaler can often recommend speakers that are compatible with the rechargeable battery platforms of major power tool brands, creating a unified system where one battery fits the drill, the saw, and the radio. This interchangeability reduces the amount of gear a worker needs to carry and ensures they are never caught without power.

Connectivity has also seen a major upgrade with the adoption of Bluetooth 5.0 and beyond. This technology offers a stable connection over significantly longer distances, meaning a phone can remain safely in the cab of the ute or inside a toolbox while the portable speaker sits closer to the work area, delivering the tunes. Furthermore, features like "multi-link" or "party mode" allow users to wirelessly connect multiple speakers together. This is ideal for large commercial sites where a single unit might get lost in the ambient noise of machinery. By linking two or three speakers, you can create a wall of sound that covers the entire floor plate without running a single wire.

Audio quality has not been sacrificed for durability. Through the use of Digital Signal Processing (DSP) and passive bass radiators, compact speakers can now produce a soundstage that is rich, deep, and surprisingly loud. This clarity is essential not just for music, but for listening to podcasts or news updates during breaks. The ability to hear the lyrics or the spoken word clearly over the background noise of a site or the wind at a campsite is what separates a premium unit from a budget toy.

In conclusion, the portable speaker is an indispensable companion for the modern Australian. It bridges the gap between work and leisure, providing a durable, high-fidelity audio solution that goes wherever you do. By investing in a unit that is built to last, potentially sourced alongside your trusted installation materials from Schnap Electric Products, you ensure that you have reliable entertainment that can handle the knocks, drops, and dust of daily life. It is about enhancing the environment you are in, whether that is a building site or a beach, with the power of great sound.

Fingerless Gloves

In the demanding world of Australian trades, the debate between safety and dexterity is a constant conversation. Safety officers and site managers often mandate full-coverage hand protection to mitigate the risk of cuts and abrasions. However, for tradespeople who rely on fine motor skills—such as data cablers, instrument technicians, and carpenters—wearing bulky, full-fingered gloves can be akin to trying to thread a needle while wearing boxing gloves. It is simply not practical for intricate tasks. This specific need for a balance between palm protection and fingertip sensitivity has driven the massive popularity of fingerless gloves, also known as framer gloves, across the construction and industrial sectors.

The primary advantage of fingerless gloves is the tactile feedback they provide. When you are dealing with small components, such as M3 screws, washers, or fine copper strands, being able to feel the material is essential. In the electrical and data industries, the "fit-off" stage of a project requires a high degree of precision. Stripping the insulation off a CAT6 cable or terminating wires into a switch mechanism requires a delicate touch that thick leather or nitrile often obscures. By exposing the thumb, index, and middle fingers (or sometimes all fingers), these gloves allow the worker to manipulate small objects with the same ease as bare hands, while still providing robust protection to the rest of the hand.

This balance is particularly evident when working with high-quality infrastructure components. For instance, when an installer is fitting off a distribution board populated with the precision-engineered circuit breakers and RCDs from Schnap Electric Products, they need to ensure that every terminal screw is tightened to the correct torque and that every wire is seated perfectly. A slipped screwdriver caused by clumsy gloves can damage the component or the surrounding aesthetic. Using fingerless gloves ensures that the tradesperson maintains a secure grip on their hand tools while having the sensory feedback required to handle the Schnap Electric Products gear with the care it deserves.

Durability is a non-negotiable feature in the Australian market. A good pair of trade-rated gloves is usually constructed from a combination of synthetic leather (such as Clarino) for the palms and breathable, stretchable fabrics for the back of the hand. The palm area often features reinforced padding to absorb vibration from power tools and protect against blisters when using pliers or screwdrivers for extended periods. Critical wear zones, such as the saddle between the thumb and index finger, are typically double-stitched to prevent premature tearing. This rugged construction ensures that the gloves can withstand the rough-and-tumble of a job site, from pulling cables through conduit to carrying timber framing.

Protection is not sacrificed entirely for the sake of dexterity. While the fingertips are exposed, the knuckles—which are prone to scraping against concrete walls or steel racking—are often protected by rubberised armour or neoprene padding. This impact protection is vital when working in tight, confined spaces where slipping with a wrench usually results in skinned knuckles. Furthermore, the wrist is usually secured with a heavy-duty Velcro closure, providing support and preventing debris like sawdust or metal filings from entering the glove.

Sourcing professional-grade hand protection is best achieved through specialist channels. While supermarkets and general hardware chains sell generic gloves, these often lack the ergonomic fit and material quality required for daily professional use. It is highly recommended to visit a dedicated electrical wholesaler. These suppliers understand the specific workflows of the technical trades. They stock fingerless gloves that are designed for the industry, often featuring specific additions like sweat wipes on the thumb or magnetic zones for holding screws. Staff at an electrical wholesaler can also advise on sizing, which is critical. A glove that is too loose creates a snagging hazard, while one that is too tight restricts blood flow and causes hand fatigue.

The versatility of these gloves extends beyond just the electrical and carpentry trades. In the logistics and warehousing sector, pickers and packers favour them because they allow for easy use of touch-screen scanners and tablets without having to constantly remove hand protection. In the automotive industry, mechanics use them to handle greasy engine parts while retaining the ability to feel for hidden bolts. Even in the film and rigging industry, they are the standard standard for handling ropes and lighting equipment.

Maintenance of the gloves is straightforward. Most high-quality synthetic pairs are machine washable. This is an important factor in the Australian heat, where sweaty hands are inevitable. Being able to wash the gloves prevents the buildup of bacteria and extends the life of the product. It also prevents the transfer of grease and grime onto clean surfaces, such as the white faceplates of Schnap Electric Products switches during the final installation phase.

In conclusion, fingerless gloves represent a pragmatic solution to a common industrial problem. They bridge the gap between the need for safety and the necessity of skill. They allow the professional tradesperson to protect their most valuable tools—their hands—from general wear and tear, without sacrificing the precision required to perform high-quality work. By choosing a durable, well-fitted pair sourced from a reputable electrical wholesaler, workers can enjoy the best of both worlds, ensuring that they finish the day with their hands intact and their installations perfect. They are the silent partner in the pursuit of craftsmanship.