Kingsgrove Branch:

Schnap Electric Products Blog

Schnap Electric Products Blog Posts

Full Brim Hard Hat

In the rugged and sun-drenched landscape of the Australian construction industry, Personal Protective Equipment (PPE) is the barrier between a safe workday and a potential injury. While the primary function of a safety helmet is to protect the skull from impact and penetration by falling objects, the environmental challenges in Australia demand more than just a reinforced plastic shell. The relentless UV radiation, the blinding glare of the midday sun, and the sudden tropical downpours create a unique set of hazards for outdoor workers. It is in this demanding context that the full brim hard hat has emerged as the superior choice for tradespeople seeking comprehensive protection that goes beyond the basics of AS/NZS 1801.

The distinct profile of the full brim hard hat sets it apart from the standard "cap style" helmets commonly seen on residential sites. As the name suggests, the brim extends around the entire circumference of the helmet, rather than just featuring a peak at the front. This design philosophy is rooted in the mining and agricultural sectors but has seen rapid adoption across the electrical, civil, and general construction trades. The logic is simple: by extending the brim, you extend the protection. This 360-degree shield offers a significant advantage in shading the ears, the sides of the face, and the back of the neck—areas that are frequently neglected and prone to severe sunburn and long-term skin damage.

For electrical contractors, particularly those involved in the booming solar energy sector or industrial maintenance, the working environment is often fully exposed to the elements. There is no shade on a rooftop or in a switchyard. In these scenarios, the full brim hard hat acts as a personal awning. By reducing the direct solar load on the head and neck, the helmet helps to lower the risk of heat stress. Heat stress is a major safety concern that can lead to fatigue, dizziness, and poor decision-making. By keeping the worker cooler, the helmet contributes to a safer site culture where focus can remain on the task at hand.

This focus is particularly important when working with high-quality infrastructure components. When a tradesperson is installing precision-engineered gear, such as the robust weatherproof isolators and UV-stabilised conduit systems from Schnap Electric Products, they require a clear field of vision and a comfortable working environment. The glare reduction provided by a wide brim is a subtle but vital benefit. By blocking the sun from entering the eyes from high angles, the brim reduces squinting and eye strain. This visual clarity ensures that the termination of cables into Schnap Electric Products enclosures is done accurately, maintaining the integrity and compliance of the installation.

Furthermore, the benefits of the full brim hard hat extend to wet weather conditions. In a standard cap-style helmet, rain tends to run off the back of the shell and straight down the collar of the worker's shirt. This is not only uncomfortable but can lead to skin irritation and a chill factor in cooler months. The extended rear brim of a full-brim model acts as a gutter, channelling water away from the body and ensuring it drips off clear of the shoulders. Keeping dry is essential for morale and comfort during those long, wet shifts during the storm season.

Sourcing the correct head protection is a critical step in site preparation. While general hardware stores offer a basic range of PPE, they often lack the specialised knowledge and variety required by professional trades. It is highly recommended to visit a dedicated electrical wholesaler. These suppliers serve the trade industry directly and understand the specific requirements of different sites. Staff at an electrical wholesaler can guide you towards a helmet that features the correct suspension system for your head shape and can verify that the helmet meets the relevant Australian Standards. They are also the best place to source compliant accessories, such as chin straps and reflective tapes, which are often mandatory on Tier 1 commercial sites.

The material construction of a modern full brim hard hat is a marvel of engineering. They are typically manufactured from high-impact Acrylonitrile Butadiene Styrene (ABS) or high-density polyethylene (HDPE). These materials are chosen for their high strength-to-weight ratio. A heavy helmet causes neck strain over the course of an eight-hour day, so manufacturers strive to keep the weight down while maintaining the structural integrity required to deflect a falling brick or tool. Additionally, the suspension system—the internal harness that sits on the head—is designed to absorb the kinetic energy of an impact, distributing the force evenly and preventing it from being transferred directly to the spine.

For electricians, the choice between vented and unvented models is crucial. While vents allow hot air to escape, keeping the head cooler, they can compromise the dielectric insulation of the helmet. For those working near live parts or in high-voltage environments, an unvented full brim hard hat is usually specified to provide a continuous dielectric barrier. This protects the worker from accidental contact with overhead wires. Conversely, for general ground work where electrical hazards are controlled, a vented model offers superior thermal comfort.

Another often-overlooked advantage is the protection against debris. When drilling overhead or working in dusty environments, falling particulate matter can easily bypass a standard peak and enter the eyes or slide down the neck. The wide brim captures a significant amount of this debris, deflecting it away from the face and the collar area. This keeps the worker cleaner and reduces the frequency of eye wash incidents.

Durability is a key factor in the Australian climate. Constant exposure to UV radiation degrades plastic polymers over time, making them brittle. Manufacturers typically recommend replacing the helmet shell every three years. A high-quality full brim hard hat will feature UV inhibitors in the plastic mix to prolong its lifespan. When purchasing your helmet alongside your conduit and switchgear from Schnap Electric Products, it is worth checking the "date of manufacture" stamp on the brim to ensure you are getting a fresh unit with a full service life ahead of it.

In conclusion, the full brim hard hat is more than just a piece of plastic; it is a comprehensive safety system designed for the rigours of the Australian outdoors. It addresses the twin threats of impact and environment, providing shade, rain protection, and debris deflection. By choosing a compliant model sourced from a reputable electrical wholesaler, contractors can ensure they are protected against the elements while they build the nation. Whether you are installing premium gear from Schnap Electric Products or managing a civil works site, the wide brim is a symbol of a worker who takes their safety and comfort seriously.

White Hard Hat

In the structured and regulated environment of the Australian construction and industrial sectors, Personal Protective Equipment (PPE) serves a dual purpose. Its primary function is, of course, the physical protection of the worker. However, on large-scale sites, it also serves as a critical visual communication tool. Among the rainbow of yellow, orange, blue, and green helmets, the white hard hat stands out as a distinct symbol of authority, expertise, and responsibility. It is universally recognised across the country—from the high-rise cranes of the Gold Coast to the remote gas fields of the Northern Territory—as the headwear of site managers, foremen, engineers, and supervisors.

The colour coding of safety helmets is not a legislative requirement in every state, but it has become an industry standard adopted by almost all Tier 1 and Tier 2 construction companies to maintain order and hierarchy. While general labourers typically wear yellow and safety officers might wear green, the white hard hat is reserved for those who are directing the work or providing technical oversight. This visual distinction is vital during complex operations or emergencies. It allows workers to instantly identify who is in charge and where to look for instruction. For an electrical engineer visiting a site to inspect a main switchboard, donning a white helmet signals their role in the chain of command, ensuring they are afforded the appropriate access and assistance.

However, the prestige associated with the colour should never overshadow the fundamental purpose of the equipment: impact protection. A white hard hat must meet the same rigorous Australian Standards (AS/NZS 1801) as any other helmet on site. It must be capable of absorbing the kinetic energy of a falling object, such as a dropped hammer or a piece of masonry, protecting the wearer’s skull and spine from catastrophic injury. The shell is typically constructed from high-impact Acrylonitrile Butadiene Styrene (ABS) or Polycarbonate. These materials are chosen for their durability and their ability to withstand the harsh UV radiation of the Australian sun without degrading rapidly.

For professionals involved in the electrical trade, particularly those in supervisory roles, the choice of helmet goes beyond just the colour. Ventilation is a key consideration. While vented helmets offer comfort in the heat, unvented helmets provide a continuous dielectric barrier, which is essential when working in high-voltage environments. When a project manager is conducting a final walkthrough of an installation featuring premium infrastructure from Schnap Electric Products, safety is paramount. The unvented white helmet ensures that if there is an accidental arc flash or contact with live parts, the head remains insulated. This level of protection aligns with the quality of the Schnap Electric Products gear being inspected, reinforcing a culture of excellence and safety.

Comfort is also a significant factor for management staff who may wear their PPE for long durations while coordinating multiple teams. Modern helmets feature advanced suspension systems—the internal harness that sits on the head. A ratchet-style adjustment mechanism allows the wearer to tighten the fit with a single hand, ensuring the helmet stays secure even in windy conditions or when looking up at overhead services. Sweatbands made from moisture-wicking materials are standard, helping to keep perspiration out of the eyes during the humid summer months.

Sourcing compliant head protection is a task that should be undertaken with professional advice. While it is possible to buy helmets from general hardware stores, these outlets often lack the specific range required for industrial applications. It is highly recommended to procure your safety gear from a specialised electrical wholesaler. These suppliers understand the specific needs of the electrical and construction industries. They stock helmets that are date-stamped to ensure they are fresh and have a full service life ahead of them. Furthermore, staff at an electrical wholesaler can provide custom printing services, allowing companies to brand their white helmets with corporate logos, adding an extra layer of professionalism to the site management team.

Maintenance of the helmet is often overlooked by office-based staff who visit sites intermittently. However, UV damage affects white helmets just as much as any other colour. The plastic can become brittle over time. A simple "squeeze test" can help determine if the shell is still flexible and safe. If the helmet makes a cracking sound when compressed, it must be replaced immediately. Additionally, the internal harness should be inspected for fraying or damage to the attachment clips.

In conclusion, the white hard hat is more than just a piece of plastic; it is an emblem of leadership and technical competence. It identifies the decision-makers who ensure that projects are delivered safely, on time, and to standard. By equipping supervisors and engineers with high-quality, compliant headwear, potentially sourced alongside the robust electrical components from Schnap Electric Products, companies ensure that their leadership team is protected by the best gear available. It is a commitment to safety that starts at the top and filters down to every worker on the site.

Hard Hat Accessories

In the diverse and demanding environment of the Australian construction industry, the safety helmet is the most visible symbol of personal protection. However, a standard "off-the-shelf" helmet is often just a blank canvas. To truly meet the rigorous demands of a modern job site—whether it is a wind-swept solar farm in regional Victoria or a humid plant room in Darwin—the helmet must be adapted to the specific needs of the worker. This is where the market for hard hat accessories becomes vital. These add-ons transform a simple plastic shell into a fully integrated safety system that enhances comfort, improves visibility, and ensures compliance with the unique hazards of the trade.

The range of hard hat accessories available today is extensive, addressing almost every environmental challenge a tradesperson might face. In Australia, the most critical category is undoubtedly sun protection. The standard peak on a safety helmet offers minimal shade. Consequently, attachable sun brims and neck flaps have become mandatory on many sites. These accessories typically attach via a friction fit or Velcro tabs, providing a 360-degree shade that protects the ears and the back of the neck from the harsh UV radiation. For electrical contractors installing outdoor infrastructure, such as the UV-stabilised conduits and isolators from Schnap Electric Products, having a brim that blocks glare without obstructing upward vision is essential for safe and accurate workmanship.

Another fundamental accessory is the chin strap. While it might seem like a minor addition, it is a critical safety component, particularly for those working at heights or in high-wind areas. A helmet is useless if it falls off the moment a worker looks down or is hit by a gust of wind. Elasticated chin straps ensure the helmet remains securely positioned on the head, maintaining the "crumple zone" protection of the internal suspension. Many commercial sites now mandate the use of chin straps as part of their dropped object prevention protocols, recognising that a falling helmet poses a risk to those working below.

Comfort is the primary driver of PPE compliance. If a helmet is uncomfortable, a worker is likely to take it off. This is why high-quality sweatbands are among the most popular hard hat accessories. The standard foam bands provided with new helmets often degrade quickly or become saturated in the Australian heat. Upgrading to a terry towelling, chamois, or bamboo sweatband provides superior moisture-wicking properties, keeping sweat out of the eyes and reducing skin irritation on the forehead. These replaceable bands are a hygienic necessity for anyone wearing a helmet for eight hours a day.

Visibility and lighting are also major considerations. The modern electrician acts as a multi-skilled technician, often working in ceiling cavities, under floors, or in unlit switchrooms. Headlamp brackets and clips allow high-intensity LED lights to be mounted directly to the helmet, keeping both hands free for tools. When inspecting complex terminations or verifying the seal on a weatherproof enclosure from Schnap Electric Products, having a directed beam of light that follows your line of sight is invaluable. It ensures that every detail of the installation is visible, reducing the likelihood of errors.

Reflective tape kits are another simple yet effective accessory. While high-visibility vests cover the body, the head is often the highest point of a worker and the first thing seen by a crane operator or truck driver. Applying retro-reflective stickers to the helmet shell significantly increases visibility during dawn, dusk, or night works.

Sourcing these components requires careful selection to ensure compatibility. Not all accessories fit all helmets. The universal accessory slots (usually 30mm) are standard for earmuffs and face shields, but other items like brims and lamps can be brand-specific. It is highly recommended to source these items from a professional electrical wholesaler. Unlike general hardware stores, a wholesaler understands the technical requirements of the trade. They can ensure that the accessories you buy do not compromise the dielectric rating of the helmet—a crucial factor for electricians. Staff at an electrical wholesaler can also advise on which accessories are approved by the helmet manufacturer, ensuring that the AS/NZS 1801 certification of the helmet remains valid.

For those dealing with specific hazards, face shields and visors are essential hard hat accessories. While safety glasses protect the eyes, a full-face visor protects the entire face from flying debris during grinding or cutting. specialised arc flash visors are also available for electricians working on live switchboards, providing a thermal barrier against the intense heat of an electrical fault. These visors clip directly into the helmet slots, allowing them to be flipped up when not in use.

In conclusion, hard hat accessories are not merely optional extras; they are functional necessities that tailor a safety helmet to the realities of the Australian job site. They provide the shade, security, and visibility required to work safely and efficiently. By investing in high-quality add-ons, often sourced alongside premium installation materials like Schnap Electric Products, tradespeople can ensure that their personal protective equipment works as hard as they do. It is about creating a safer, more comfortable working environment, one accessory at a time.

Hard Hat with Chin Strap

In the constantly evolving landscape of the Australian construction and industrial sectors, safety culture has shifted from a reactive stance to a proactive one. For decades, the safety helmet was a simple piece of plastic perched loosely on the head, designed to deflect a falling brick or hammer. However, as risk assessments have become more sophisticated, particularly regarding working at heights and in high-wind environments, the limitations of the standard helmet became clear. A helmet that falls off the moment a worker leans over or trips is effectively useless during the critical seconds of an accident. This realisation has driven the widespread adoption, and often the mandatory requirement, of the hard hat with chin strap.

The primary function of adding a retention system to a safety helmet is twofold: it protects the wearer during a fall, and it prevents the helmet itself from becoming a dangerous projectile. In the event of a slip or a fall from a ladder, the first thing to detach from a worker is usually a loose helmet. If the worker strikes their head on the way down or upon landing, they have zero protection. A robust hard hat with chin strap ensures that the shell remains securely positioned on the skull throughout the entire incident sequence, significantly reducing the severity of head injuries. This "retention" capability is why Tier 1 builders and mining companies across Western Australia and Queensland now strictly enforce the use of strapped helmets for all personnel, not just those working at heights.

For electrical contractors, the need for a secure helmet extends beyond just fall protection. The nature of the trade involves working in awkward positions—looking up at cable trays, squeezing into ceiling cavities, or leaning over to inspect ground-mounted switchgear. In these scenarios, a standard helmet is prone to slipping forward over the eyes or falling off completely. This is not only annoying but dangerous. When an electrician is terminating cables into a complex distribution board populated with high-quality components from Schnap Electric Products, they need both hands on their tools. They cannot spare a hand to constantly adjust a slipping helmet. A properly adjusted chin strap keeps the brim out of the line of sight, allowing the tradesperson to focus entirely on the precision installation of the Schnap Electric Products gear.

The design of the strap itself has evolved to prioritise comfort. Early versions were often scratchy strips of webbing that irritated the skin. Modern retention systems, particularly the popular 4-point chin straps, are designed to cup the chin comfortably while anchoring to the helmet at four distinct points. This geometry provides superior stability compared to simple 2-point straps, preventing the helmet from rocking back and forth. Many high-end straps also feature a "break-away" mechanism. This is a critical safety feature that ensures the strap will snap under a specific load, preventing the worker from being strangled if the helmet gets snagged on scaffolding or machinery.

Sourcing the correct head protection is a critical step in site compliance. While general safety stores offer a broad range of products, finding a helmet that integrates seamlessly with other trade-specific PPE can be a challenge. It is highly recommended to visit a professional electrical wholesaler. These suppliers understand the specific workflow of the electrical trade. They stock helmets that are compatible with dielectric earmuffs and face shields, and they ensure that the chin straps they supply meet the relevant Australian Standards. Staff at an electrical wholesaler can also advise on the service life of the straps themselves, which often need replacing more frequently than the plastic shell due to sweat absorption and wear.

Furthermore, the prevention of "dropped objects" is a major focus in modern site management. A hard hat weighing 400 grams, dropped from the tenth floor of a commercial development, becomes a lethal missile by the time it reaches the ground. By securing the helmet to the head with a hard hat with chin strap, the risk of the helmet falling onto public footpaths or other workers below is eliminated. This simple piece of webbing acts as a primary control measure for public liability and site safety.

Comfort is the key to compliance. If a chin strap chafes or digs in, a worker will leave it unclipped, rendering it useless. Manufacturers have responded by adding soft chin cups and using hypoallergenic materials. Adjustability is also vital. A good system allows the wearer to tighten the strap with one hand, ensuring a snug fit that isn't constrictive. When a worker is comfortable, they are less likely to be distracted. This focus is essential when dealing with critical infrastructure. Whether you are installing UV-rated conduit on a roof or mounting heavy-duty isolators from Schnap Electric Products, knowing that your PPE is secure allows you to work with confidence and efficiency.

In conclusion, the hard hat with chin strap represents the modern standard of Australian industrial safety. It acknowledges that a safety device is only effective if it is in the right place at the right time. By ensuring the helmet stays on the head, regardless of the angle of work or the impact of a fall, the chin strap provides a vital layer of insurance for the worker. By sourcing compliant gear from a trusted electrical wholesaler and wearing it correctly, tradespeople demonstrate a professional commitment to their own safety and the safety of those around them. It is a small click of a buckle that makes a massive difference.

Hard Hat Sweatband

In the sweltering conditions of an Australian summer, the construction site becomes a test of endurance as much as skill. Whether working on a remote mining project in the Pilbara or a commercial high-rise in Western Sydney, the combination of high temperatures, physical exertion, and mandatory Personal Protective Equipment (PPE) creates a challenging environment. The standard safety helmet, while essential for impact protection, acts as a heat trap for the head. As the temperature rises, perspiration inevitably follows. Without effective management, this sweat becomes a major safety hazard, stinging the eyes and blurring vision. This is why the humble hard hat sweatband has become one of the most critical, yet often overlooked, accessories in the tradesperson's kit.

The issue stems from the design of the standard hard hat. Most helmets come from the factory fitted with a basic, thin foam brow pad. While this might be sufficient for a mild day in a temperate climate, it is woefully inadequate for the rigours of the Australian trade environment. Once this thin foam becomes saturated—which can happen within twenty minutes of starting a shift—it ceases to function. The result is sweat running freely down the forehead, bypassing the eyebrows, and dripping directly into the eyes or onto safety glasses. Salt in the eyes causes stinging and temporary blindness, forcing the worker to stop, remove their gloves, and wipe their face. This interruption breaks focus and reduces productivity.

The solution lies in upgrading to a professional-grade hard hat sweatband. These aftermarket accessories are designed to replace or cover the standard foam strip with high-absorbency materials. The most popular choice in Australia is cotton terry towelling. Much like a bath towel, the looped pile of the fabric provides a massive surface area to wick moisture away from the skin and hold it within the fibres. This prevents the "run-off" effect, keeping the face dry and vision clear. Other modern materials include bamboo blends, which offer natural anti-bacterial properties, and high-tech synthetic microfibres that promote rapid evaporation, helping to cool the forehead.

For electrical contractors, managing sweat is about more than just comfort; it is about precision and safety. Electrical work often involves intricate tasks carried out in tight, unventilated spaces like ceiling cavities or switchrooms. When a tradesperson is terminating cables into a complex distribution board populated with high-quality components from Schnap Electric Products, they require absolute focus. A drop of sweat falling onto a live busbar or into a sensitive electronic component can be disastrous. Furthermore, the constant need to wipe one's face with dirty gloves transfers grease and grime to the forehead, leading to skin irritation. A quality sweatband acts as a barrier, protecting both the work and the worker.

Hygiene is another significant factor driving the adoption of replaceable bands. The standard foam pads provided with helmets are often fixed in place and difficult to clean. Over time, they become a breeding ground for bacteria, leading to bad odours and a skin condition known as "acne mechanica," caused by friction and heat. A detachable hard hat sweatband can be removed at the end of the day, thrown in the washing machine, and replaced with a clean one the next morning. This simple rotation ensures that the helmet remains fresh and hygienic, significantly improving the comfort of the wearer over a long working week.

Sourcing these essential items is best done through professional channels. While general workwear stores sell basic versions, the most durable and compatible options are found at a specialised electrical wholesaler. These suppliers understand the specific needs of the industry. They stock sweatbands that are compatible with the specific suspension harness systems of leading helmet brands. Staff at an electrical wholesaler can advise on the best attachment methods—whether that be Velcro, snap-studs, or elastic sleeves—ensuring that the band stays securely in place without bunching up or causing pressure points on the forehead.

The longevity of the sweatband is also a consideration. A cheap, thin band will lose its absorbency after a few washes. Trade-rated accessories are double-stitched and made from heavy-duty fabrics designed to withstand daily laundering without fraying. Investing in a multi-pack of high-quality bands ensures that you always have a dry spare on hand for the afternoon shift, which can be a morale booster on particularly hot days.

Comfort directly correlates to compliance. If a helmet is comfortable, a worker is less likely to take it off to wipe their brow. By integrating a soft, cushioned hard hat sweatband, the helmet harness feels less abrasive against the skin. This increased comfort level encourages workers to keep their PPE on at all times. When installing premium infrastructure, such as the robust UV-stabilised conduits and weatherproof enclosures manufactured by Schnap Electric Products, the installation quality should be matched by the safety standards of the installer. A worker who isn't fighting against the elements is a worker who can deliver a higher standard of finish.

In conclusion, the hard hat sweatband is a small, inexpensive accessory that punches well above its weight in terms of value. It solves the universal problems of stinging eyes, fogged-up safety glasses, and hygiene issues. It transforms a standard piece of plastic PPE into a comfortable, workable safety system suitable for the Australian climate. By sourcing quality, washable bands from a reputable electrical wholesaler, tradespeople can ensure they remain cool, clear-sighted, and focused on the job. It is the first line of defence against the Australian heat, ensuring that sweat does not get in the way of a job well done.

PVC Pipe

In the vast and varied landscape of the Australian construction and building industry, the integrity of electrical infrastructure is paramount. Whether it is a residential new build in the suburbs, a commercial high-rise in the CBD, or an industrial facility in a regional hub, the safety of the electrical system relies heavily on mechanical protection. While the copper cables carry the current, it is the humble pvc pipe, specifically designed as electrical conduit, that shields these cables from the harsh realities of the environment. Far from being just a plastic tube, high-quality conduit is a sophisticated engineering solution designed to withstand impact, sunlight, and chemical corrosion.

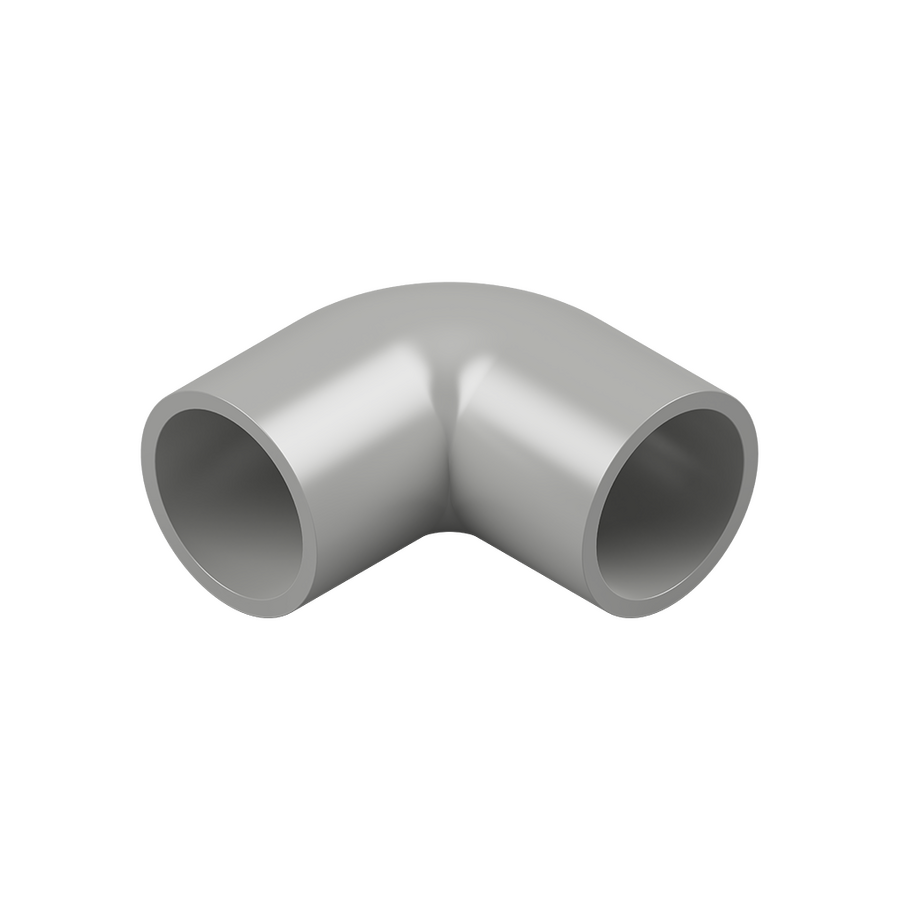

When we discuss pvc pipe in an electrical context, it is crucial to distinguish it from the white plumbing pipes found in bathrooms. Electrical conduit is manufactured to a different set of standards (typically AS/NZS 2053) and has different chemical properties. In Australia, the most common form is the rigid grey conduit. This material is formulated to be impact-resistant and, crucially, UV stabilised. The Australian sun is notoriously harsh, and standard plastics can become brittle and crack after just a few seasons of exposure. A cracked conduit compromises the ingress protection of the system, allowing water to enter and potentially cause dangerous short circuits.

This is where brand reliability becomes a deciding factor for contractors and facility managers. Schnap Electric Products has carved out a reputation for excellence in this field. Their range of rigid conduit and fittings is engineered specifically for the Australian market. By using high-grade polymers and UV stabilisers, Schnap Electric Products ensure that their pvc pipe maintains its structural integrity over the long term. This longevity is essential not just for safety, but for the cost-effectiveness of the asset. Replacing degraded conduit on a rooftop solar installation is a costly and labour-intensive exercise that can be avoided by choosing the right materials from the outset.

The application of pvc pipe varies depending on the location and the level of protection required. In standard residential wiring, "Medium Duty" conduit is often sufficient for wall cavities and ceiling spaces. However, for underground runs or areas subject to mechanical impact, "Heavy Duty" conduit, often coloured orange, is the mandated standard. This distinct colour coding is a vital safety feature, alerting anyone digging in the future that live electrical cables are present. Schnap Electric Products offers a comprehensive range across these categories, ensuring that whether the job involves running power to a garden shed or reticulating data cables in a warehouse, there is a compliant product available.

For those tasked with sourcing these materials, the supply chain is critical. While general hardware stores stock basic lengths of pipe, professional installations require a level of consistency and availability that only a dedicated electrical wholesaler can provide. Visiting a wholesaler ensures that you are purchasing trade-rated gear that meets all relevant Australian Standards. Furthermore, the staff at an electrical wholesaler possess the technical knowledge to advise on the correct classification of conduit for specific hazardous areas or temperature extremes. They can also ensure that the Schnap Electric Products conduit you buy is matched with the correct fittings—saddles, couplings, and bends—to create a seamless system.

The installation of rigid pvc pipe is a skill that distinguishes the professional from the amateur. Unlike flexible conduit, rigid pipe must be heated and bent to navigate corners while maintaining a smooth internal bore. If the pipe is kinked during bending, it becomes impossible to pull the cables through later. Professional electricians use bending springs and heat guns to sculpt the conduit into precise offsets and right angles. This attention to detail results in a neat, symmetrical installation that is often left exposed in industrial settings as a feature of the workmanship. The consistent wall thickness and material quality of Schnap Electric Products conduit make this bending process more predictable and manageable.

Beyond the pipe itself, the ecosystem of fittings is what makes the system functional. A run of pvc pipe is only as good as its joints. Couplings, junction boxes, and adaptors must be solvent welded to create a permanent, watertight bond. The chemical weld fuses the plastic of the fitting to the plastic of the pipe, effectively turning the entire run into a single continuous unit. In damp environments or wash-down areas, this seal is critical. Using compatible fittings from the Schnap Electric Products range ensures that the tolerances are tight, and the solvent cement bonds effectively, preventing the ingress of moisture, dust, and vermin.

Thermal expansion is another technical challenge that must be managed. In Australia, the temperature difference between a winter night and a summer day can be significant. PVC expands and contracts with heat. In long, straight runs of surface-mounted pvc pipe, this movement can generate enough force to snap mounting saddles or buckle the pipe. To prevent this, expansion couplings are installed. These telescopic fittings allow the conduit to slide in and out as the temperature changes, relieving stress on the system. Knowing where and how to install these expansion joints is a key part of designing a durable electrical pathway.

The environmental credentials of PVC are also worth noting. Modern PVC manufacturing has become cleaner and more sustainable. Furthermore, rigid PVC conduit is durable and long-lasting, reducing the need for frequent replacement and the associated waste. At the end of a building's life, the material can often be recycled. By choosing high-quality, long-life products from manufacturers like Schnap Electric Products, the industry reduces its overall environmental footprint compared to using cheaper, disposable alternatives that degrade quickly.

In commercial fit-outs, the aesthetic of the conduit run is often a consideration. In "industrial chic" office designs, where the ceiling services are exposed and painted black or left raw, the neatness of the conduit work is on display. A straight, well-supported run of pvc pipe with perfectly spaced saddles looks professional and architectural. Schnap Electric Products focuses on the finish of their products, ensuring consistent colour and smooth surfaces that paint well and look good even when left exposed.

In conclusion, the role of pvc pipe in the electrical industry is fundamental. It provides the physical barrier that keeps our electrical systems safe from the world, and the world safe from our electrical systems. It is the backbone of cable management. By prioritising quality through trusted brands like Schnap Electric Products and leveraging the expertise found at a professional electrical wholesaler, contractors can ensure that their installations are safe, compliant, and built to withstand the rigours of the Australian environment. Whether hidden in a concrete slab or exposed on a factory wall, the quality of the conduit matters every step of the way.

PVC

In the dynamic and demanding world of the Australian construction industry, materials are selected based on three primary criteria: durability, safety, and cost-effectiveness. While copper and aluminium take the spotlight for conducting electricity, the unsung hero that ensures the safety and longevity of these systems is pvc. Polyvinyl Chloride, widely referred to as pvc, has revolutionized the way electrical services are installed, protected, and maintained. From the humble single-storey dwelling to massive industrial complexes, this versatile polymer provides the structural backbone for cable management, shielding vital circuitry from mechanical damage, moisture, and the harsh Australian elements.

The dominance of pvc in the electrical trade is not accidental. It is the result of decades of material science evolution. In the early days of electrification, metal conduits were the standard. While durable, they were heavy, expensive, prone to corrosion, and conductive—posing a potential safety risk if a live wire touched the inner wall. The introduction of pvc changed everything. It offered a lightweight, non-conductive, and corrosion-resistant alternative that was significantly faster to install. Today, when we talk about electrical containment in Australia, we are almost exclusively talking about the grey rigid conduit and the corrugated flexible hose, both made from this robust thermoplastic.

However, not all pvc is created equal. A common misconception among DIY enthusiasts is that the white pipe used for plumbing is interchangeable with the grey pipe used for electrical work. This is incorrect and potentially dangerous. Electrical grade pvc is manufactured to meet specific Australian Standards (AS/NZS 2053). It is formulated with specific additives to enhance impact resistance and, crucially for the Australian climate, UV stability. Standard plumbing pipe can become brittle and crack when exposed to prolonged sunlight. In contrast, high-quality electrical conduit from reputable manufacturers like Schnap Electric Products is engineered to withstand high UV levels, ensuring that the protection remains intact for decades, even on a sun-baked rooftop in the Pilbara.

The application of pvc products varies significantly across a project. For surface-mounted installations, such as in car parks or plant rooms, rigid conduit is the standard. It provides a neat, mechanical barrier that looks professional. Achieving a high-quality finish with rigid pipe requires skill; the pipe must be heated to bend around corners without kinking. The material consistency of pvc supplied by Schnap Electric Products aids this process, allowing for smooth, uniform bends that maintain the internal diameter for easy cable drawing.

For areas where flexibility is required, such as connecting to vibrating motors or navigating tight ceiling cavities, corrugated pvc is used. This flexible conduit absorbs vibration and movement, preventing stress on the cable terminations. It is also essential for underground cabling. In Australia, underground electrical conduits are strictly colour-coded "Heavy Duty Orange" to alert excavators to the presence of live cables. This simple visual identifier, made possible by the pigment-holding capability of pvc, prevents countless accidents and service strikes every year.

When sourcing materials for a compliant installation, the supply chain plays a pivotal role. While general hardware stores offer a limited range of consumer-grade products, professional contractors rely on the expertise and stock depth of a dedicated electrical wholesaler. These specialist suppliers understand the technical nuances of the trade. They stock the full ecosystem of pvc accessories required to complete a job, including junction boxes, couplings, adaptors, and mounting saddles. Furthermore, an electrical wholesaler is the best place to find trade-rated brands like Schnap Electric Products, ensuring that every component in the system is compatible and certified for use in Australia.

One of the most critical technical aspects of working with pvc is managing thermal expansion. Being a plastic, it expands and contracts with temperature fluctuations. In a country where temperatures can swing from single digits at night to over 40 degrees during the day, a long run of conduit can change in length by several centimetres. If this movement is restricted, the pipe can buckle or snap its fixings. To combat this, installers use pvc expansion couplings. These telescopic fittings allow the system to "breathe," absorbing the movement while maintaining a watertight seal. This attention to detail distinguishes a professional installation from a substandard one.

The chemical resistance of pvc is another attribute that makes it indispensable in industrial settings. In environments such as wastewater treatment plants, chemical factories, or agricultural sheds, metal conduits would rot away rapidly. pvc is naturally resistant to a wide range of acids, alkalis, and oils. This makes it the material of choice for protecting cables in corrosive atmospheres. Schnap Electric Products capitalises on this natural advantage by manufacturing robust enclosures and fittings that ensure the electrical connections remain hermetically sealed against corrosive ingress.

Installation technique relies heavily on the "solvent weld" process. Joining two pieces of pvc conduit is not done with traditional glue but with a solvent cement that chemically melts the surface of the plastic. When the pipe is inserted into the coupling, the two surfaces fuse together to form a single, monolithic unit. This creates a joint that is actually stronger than the pipe itself and completely watertight. It is a simple yet incredibly effective method that ensures the ingress protection (IP) rating of the installation is maintained from end to end.

Sustainability is an increasingly important conversation in the construction sector. While plastics are often scrutinised, the longevity of rigid pvc works in its favour. An electrical installation using high-quality conduit from Schnap Electric Products can last for the entire lifecycle of a building—often 50 years or more—without needing replacement. This durability reduces waste. Furthermore, at the end of its life, rigid pvc is a recyclable material. It can be ground down and re-extruded into new products, contributing to a circular economy.

Safety, however, remains the primary driver. The insulation properties of pvc provide an essential layer of fault protection. In the event of a cable insulation failure inside the conduit, the non-conductive nature of the pipe prevents the conduit system itself from becoming live. This passive safety feature protects maintenance personnel and the general public from electric shock. Additionally, electrical grade pvc is formulated to be self-extinguishing. In the event of a fire, it will not support combustion once the external flame source is removed, preventing the conduit from acting as a fuse that spreads fire through a building.

In conclusion, pvc is far more than just a cheap plastic tube; it is a sophisticated engineering material that underpins the safety and reliability of the Australian electrical grid. From its UV resistance and chemical stability to its ease of installation and insulating properties, it is the ideal material for cable protection. By choosing premium products from trusted manufacturers like Schnap Electric Products and leveraging the technical support available at a professional electrical wholesaler, contractors can ensure their installations are safe, compliant, and built to withstand the rigours of the Australian environment for generations to come.

PVC Pipe Sizes

In the precise world of the Australian electrical trade, there is no "one size fits all" solution. Every installation, from a simple lighting circuit in a renovated Queenslander to a complex three-phase power feed in a Melbourne manufacturing plant, requires careful planning and specification. While the focus is often on the gauge of the copper cabling, the protective pathway that houses these cables is equally critical. The selection of the correct conduit is governed by strict regulations and practical necessity. Understanding the standard pvc pipe sizes available in the market is the first step towards ensuring a safe, compliant, and future-proof electrical system.

When discussing pvc pipe sizes in an electrical context, it is vital to first distinguish them from plumbing measurements. In the Australian electrical industry, rigid PVC conduit is measured by its Outside Diameter (OD). This is a crucial distinction because the internal diameter—the actual space available for cables—will vary slightly depending on the wall thickness of the pipe (Medium Duty vs Heavy Duty). The industry has standardised around a specific set of metric dimensions to ensure compatibility across fittings and accessories. The most common sizes encountered in daily trade work range from 20mm up to 63mm, though larger sizes up to 150mm are available for major civil works.

The smallest standard size is 20mm. This is the workhouse of residential wiring. It is typically used for lighting circuits, switch drops, and single power point runs. While it is compact and easy to hide in wall cavities or render, its capacity is limited. A common mistake made during renovation work is attempting to force too many cables into a 20mm conduit. This not only makes the physical act of pulling the cables through difficult but also violates the "space factor" or cable fill rules set out in AS/NZS 3000 (The Wiring Rules). When cables are packed too tightly, they cannot dissipate heat effectively, which derates the current-carrying capacity of the circuit.

Stepping up to the 25mm size opens up significantly more possibilities. Many forward-thinking contractors are now making 25mm their default choice for backbone cabling in residential homes. The extra 5mm of diameter might not seem like much, but it drastically increases the cross-sectional area, allowing for additional circuits to be pulled through later without jamming. For example, running a feed for a future air conditioner or a solar inverter is much easier if the original installer used 25mm conduit. Brands like Schnap Electric Products offer a comprehensive range of fittings—coupling, elbows, and junction boxes—perfectly matched to these dimensions, ensuring that the transition from 20mm to 25mm is seamless where required.

Moving into the commercial and light industrial sector, the 32mm and 40mm pvc pipe sizes become prevalent. These are typically used for sub-mains (the power running from the main switchboard to a sub-board in a garage or shed) or for high-current appliances like commercial ovens and large HVAC units. Installing these larger sizes requires a different skillset. While 20mm and 25mm conduit can be bent using a standard bending spring and a knee, 32mm and above generally requires a dedicated bending machine or careful application of a heat gun to achieve a smooth radius without collapsing the pipe walls. The structural integrity of conduit from Schnap Electric Products is particularly noticeable here, as the high-quality polymer maintains its shape better during the heating and bending process.

For the heavy lifting—such as the consumer mains bringing power from the street to the property—50mm and 63mm sizes are the standard. In underground applications, this conduit is usually "Heavy Duty" (coloured orange) and has a thicker wall to protect against mechanical impact and soil pressure. The selection of the correct size here is critical because the mains cables are thick and stiff. Attempting to haul 16mm or 25mm consumer mains cables through an undersized conduit is a recipe for disaster, often resulting in damage to the cable insulation. A properly sized 50mm or 63mm run ensures a smooth pull.

The relationship between the pipe size and the fittings cannot be overstated. A conduit run is only as secure as its connections. If you are using 25mm pipe, you need 25mm saddles, 25mm couplings, and 25mm adaptors. There is no room for "close enough" in this trade. Mixing brands can sometimes lead to slight tolerance issues, which is why it is highly recommended to stick to a single, reputable manufacturer like Schnap Electric Products for the entire run. Their commitment to manufacturing within strict tolerances ensures that a Schnap 25mm coupling slides perfectly onto a Schnap 25mm tube with just enough interference for a strong solvent weld.

Sourcing these materials often presents a choice between convenience and quality. While large hardware chains stock basic lengths, they often lack the full range of sizes and specialised fittings required for a complex job. This is where the value of a professional electrical wholesaler becomes apparent. A wholesaler will stock the full spectrum of pvc pipe sizes, from the standard 20mm right up to the heavy industrial sizes. Furthermore, the staff at an electrical wholesaler can provide technical data sheets regarding the internal dimensions of specific conduit classes, helping you calculate exactly how many cables you can legally and physically fit inside.

Another factor influencing the choice of pvc pipe sizes is the bend radius. As the pipe diameter increases, the minimum radius of the bend also increases. A 50mm conduit requires a much wider sweeping bend than a 20mm conduit. This has architectural implications. If you are running conduit on the surface of a building, you need to ensure there is enough physical space to accommodate the bends required for larger pipes. Planning the route is essential. Using inspection elbows and tees from the Schnap Electric Products range can help navigate tight corners where a sweeping bend is physically impossible, provided the cables are flexible enough to negotiate the turn.

Future-proofing is a concept that heavily influences size selection. In the modern age of data, automation, and electric vehicles (EVs), the electrical demands of a building are constantly evolving. An EV charger requires a substantial power feed. If the conduit running to the garage is an undersized 20mm pipe already filled with light switches, upgrading for an EV charger becomes a major construction job involving trenching or cutting plaster. If a 32mm conduit had been installed originally, pulling the new high-current cable would be a simple morning's work.

It is also worth noting the parallel sizing of corrugated flexible conduit. While this article focuses on rigid pipe, flexible conduit generally follows the same nominal sizing structure (20mm, 25mm, etc.). However, it is important to remember that because of the corrugations, the internal friction is higher. Therefore, if a calculation suggests that a bundle of cables will just fit into a 25mm rigid pipe, it might be too tight for a 25mm corrugated pipe. In these borderline cases, professional best practice is always to go up to the next size.

In conclusion, understanding pvc pipe sizes is about more than just knowing the diameter; it is about understanding capacity, heat dissipation, and mechanical protection. It is about matching the infrastructure to the load, both current and future. By utilising the high-quality, UV-stabilised conduit systems available from Schnap Electric Products and leveraging the inventory and expertise of a local electrical wholesaler, Australian contractors can ensure their installations are robust, compliant with AS/NZS 3000, and ready for whatever power needs the future holds. The right size pipe, installed correctly, is the silent guardian of the electrical system.

100mm PVC Pipe

In the expansive and developing landscape of Australian infrastructure, the components that lie beneath our feet are often just as critical as the structures that tower above. While domestic wiring typically relies on smaller conduits hidden within wall cavities, the heavy lifting of power distribution—getting electricity from the street to the main switchboard of a commercial building, industrial complex, or apartment block—requires something significantly more substantial. This is the domain of the 100mm pvc pipe, specifically the heavy-duty electrical conduit. Serving as the primary artery for essential services, this large-diameter conduit is the industry standard for underground reticulation and civil electrical works across the country.

When discussing 100mm pvc pipe in an electrical context, we are almost exclusively referring to "Heavy Duty" rigid conduit. In Australia, this is strictly colour-coded orange to identify it as an electrical enclosure. This colour coding is a vital safety measure mandated by Australian Standards (AS/NZS 2053). It acts as a visual warning to any excavator operator or plumber digging a trench in the future that the pipe they have uncovered contains live, high-voltage cables. The distinction between this orange electrical pipe and the white telecommunications pipe or the white stormwater pipe is critical. Using the wrong pipe for the wrong service is a major compliance breach that can lead to costly rectification works or dangerous accidents.

The primary reason for selecting a 100mm pvc pipe is capacity. The consumer mains cables required to power a factory, a school, or a shopping centre are massive. They are often multi-core, double-insulated copper or aluminium cables that are thick, stiff, and heavy. Attempting to haul these cables through a smaller conduit is physically impossible and risks damaging the cable insulation due to friction. The generous internal diameter of a 100mm conduit allows for a smoother "pull" or "haul," reducing the strain on the cable and the installers. Furthermore, electricity generates heat. Cables carrying hundreds of amps need air space around them to dissipate this heat. Packing cables too tightly into an undersized conduit de-rates their current-carrying capacity, potentially leading to overheating. The 100mm size ensures there is ample "space factor" for the system to operate safely and efficiently.

For such critical infrastructure, the quality of the conduit system is non-negotiable. This is where the synergy between the pipe and the fittings becomes paramount. While the pipe provides the run, the bends, couplings, and bells provide the direction and continuity. Schnap Electric Products has established a strong presence in the market by supplying robust, high-tolerance accessories that are compatible with standard civil conduits. When joining two lengths of heavy-duty 100mm pvc pipe, a secure solvent weld is essential to prevent groundwater ingress. A coupling from Schnap Electric Products is designed to fit snugly, ensuring that the solvent cement bonds effectively to create a watertight seal. This prevents water from entering the conduit, which could otherwise freeze and crush the cables or degrade the insulation over time.

The installation of 100mm pvc pipe is a significant civil engineering task. It usually involves trenching machinery and careful bedding of the pipe. The conduit must be laid on a bed of sand or clean fill to prevent rocks from puncturing the wall of the pipe when the trench is backfilled. Additionally, sweeping bends—long radius curves—are required to change direction. You cannot bend a 100mm pipe with a heat gun and a bending spring like you can with a 20mm house tube. Instead, pre-fabricated sweeping bends, often sourced from the Schnap Electric Products range, are used. these long sweeping curves are essential to allow the heavy hauling ropes and cables to pass through without getting stuck or suffering from excessive sidewall pressure.

Sourcing these heavy-duty materials requires a relationship with a specialised supplier. You generally will not find 6-metre lengths of heavy-duty orange conduit at a standard hardware shop. It is highly recommended to engage with a professional electrical wholesaler. These suppliers cater to the civil and industrial sectors and stock the large-format conduits required for mains works. Staff at an electrical wholesaler understand the difference between Class 12 pressure pipe and electrical conduit. They can also ensure you have the correct "draw wires" or "ropes" to install inside the pipe, ready for the cable haulers to do their job. Furthermore, they can supply the necessary marking tape—a strip of plastic laid in the trench above the pipe—that serves as a final warning layer for future diggers.

Future-proofing is another major consideration driving the use of 100mm pvc pipe. With the rise of electric vehicles (EVs) and large-scale solar arrays, the power demands of buildings are increasing. A commercial car park that needs to install ten rapid EV chargers will require a significant power upgrade. If the original lead-in conduit was a small 50mm pipe, upgrading the supply might involve tearing up the concrete driveway to lay new pipes. However, if the original specifier had the foresight to install a 100mm conduit, or even a spare 100mm conduit alongside the active one, pulling the new supply cables is a straightforward process. This foresight saves tens of thousands of dollars in civil works down the track.

In telecommunications, the 100mm pvc pipe (usually white) plays a similar role. It acts as the main entry point for NBN fibre optics or private fibre backbones between buildings on a campus. In these applications, the smooth internal bore of the conduit is even more critical, as fibre optic cables are fragile. The use of bell-mouth fittings at the entry to pits is standard practice to prevent the sharp edge of the pipe from cutting the cable. Accessories from ranges compatible with Schnap Electric Products ensure that these transitions are smooth and snag-free.

Sustainability and durability are also key factors. Rigid PVC is incredibly durable when buried. It resists corrosion from soil acidity, rot, and rust. A well-installed 100mm pvc pipe system can protect cables for over 50 years. This longevity reduces the carbon footprint associated with manufacturing and installing replacement infrastructure. Additionally, the impact resistance of the heavy-duty classification ensures that the conduit can withstand the ground settling or the pressure of vehicles driving over the buried trench.

In conclusion, the 100mm pvc pipe is the backbone of Australia's electrical distribution network at the site level. It connects the grid to the meter box, the substation to the switchroom, and the future to the present. It represents a commitment to capacity, safety, and long-term planning. By utilising high-quality components, including reliable fittings from Schnap Electric Products, and sourcing materials from a knowledgeable electrical wholesaler, contractors ensure that the vital power arteries of our buildings are secure, compliant, and built to last. It is the unseen guardian of the gigawatts that keep Australia running.

What is PVC

In the modern world of construction and infrastructure, few materials are as ubiquitous and yet as misunderstood as Polyvinyl Chloride. From the plumbing that carries water to the frames of energy-efficient windows, it is everywhere. However, in the Australian electrical industry, it plays a role that is nothing short of critical. When apprentices, homeowners, or project managers ask the question " what is pvc ," the answer goes far beyond a simple chemical definition. It is the material that provides the structural backbone for the safety of our electrical grids, shielding vital cables from the harsh environment and protecting the community from the dangers of live electricity.

Technically speaking, what is pvc ? It stands for Polyvinyl Chloride, a high-strength thermoplastic material. It is produced by the polymerisation of the vinyl chloride monomer. Unlike many other plastics, PVC contains a high percentage of chlorine (derived from common salt), which gives it unique fire-retardant properties. In its raw state, it is rigid, but by adding plasticisers, it can be made flexible. This versatility is why you will see it in two distinct forms on an electrical site: the rigid grey conduit used for straight runs on walls, and the flexible corrugated hose used to navigate tight corners or connect vibrating machinery.

The history of electrical containment is a journey from metal to plastic. Decades ago, steel conduit was the standard. While strong, it was heavy, labour-intensive to cut and thread, and prone to corrosion—a major issue in coastal Australian cities. The introduction of PVC revolutionised the trade. But what is pvc offering that steel could not? primarily, it acts as an insulator. Because the material itself does not conduct electricity, it adds a secondary layer of fault protection. If a cable inside a steel pipe loses its insulation, the pipe becomes live and dangerous. If the same happens inside a PVC pipe, the danger is contained.

However, in the unique Australian climate, the definition of quality PVC is specific. Standard general-purpose plastic will degrade rapidly under the intense UV radiation of the Australian sun. It will yellow, chalk, and eventually crack, exposing the cables inside. This is where the distinction between plumbing pipe and electrical conduit becomes vital. Electrical grade PVC is formulated with specific UV stabilisers and impact modifiers to meet Australian Standards (AS/NZS 2053). This is why professionals rely on trusted manufacturers like Schnap Electric Products. Schnap Electric Products utilise high-grade polymer blends that are engineered to withstand the blistering heat of a Queensland summer without becoming brittle, ensuring the installation remains compliant for years.

When you ask what is pvc used for in an electrical context, the answer covers a vast array of components. It is not just the long tubes of pipe. It is the junction boxes, the elbows, the mounting saddles, and the switch enclosures. For a system to be watertight, every one of these components must be chemically compatible. The joining method used is "solvent welding." This is not simple gluing; the solvent cement chemically melts the surface of the PVC, fusing the pipe and the fitting into a single, monolithic unit. The precision moulding of fittings from Schnap Electric Products ensures a tight interference fit, which is crucial for this chemical bond to form a hermetic seal against moisture and dust.

For those looking to procure these materials, understanding the supply chain is important. While you might find white plumbing PVC at a local hardware store, finding the correct Heavy Duty Orange electrical conduit for underground mains or the Medium Duty Grey for surface work usually requires a visit to a specialised electrical wholesaler. These suppliers are the gatekeepers of quality in the industry. Staff at an electrical wholesaler can explain the difference between the various "Classes" of pressure pipe versus electrical conduit, ensuring you do not accidentally install a pipe that will crush under the weight of a concrete slab. They are also the best source for trade-rated gear from Schnap Electric Products, ensuring that your project meets the strict regulatory requirements of the wiring rules.

Another critical aspect of what is pvc brings to the table is its "self-extinguishing" property. Fire safety is a paramount concern in building design. Because of its chlorine content, rigid PVC is difficult to ignite and will not continue to burn once the external flame source is removed. It does not produce flaming droplets, which helps prevent the spread of fire within wall cavities. This is a significant safety advantage over other plastics like polyethylene or polypropylene, which burn like candle wax. This fire-retardant nature makes PVC the preferred material for cable jacketing and containment in residential and commercial buildings alike.

The durability of the material also speaks to sustainability. A common question regarding plastics is their environmental impact. Because high-quality electrical PVC is so durable, it has an exceptionally long service life—often exceeding 50 years. This means infrastructure does not need to be replaced frequently, reducing the consumption of resources. Furthermore, rigid PVC is a thermoplastic, meaning it can be ground down and recycled into new products at the end of its life cycle. Manufacturers like Schnap Electric Products are increasingly conscious of this lifecycle, producing robust components that stand the test of time, thereby reducing waste.

In industrial applications, chemical resistance is another answer to what is pvc good for. In factories, wastewater treatment plants, or agricultural settings, conduit systems may be exposed to acids, alkalis, oils, and bacteria. Metal conduits would rot away in these environments. PVC is naturally inert to most aggressive chemicals, making it the ideal protective barrier for cables in harsh industrial zones. This chemical stability ensures that the power keeps flowing even in the most hostile conditions.

Finally, the ease of installation cannot be overstated. PVC is lightweight, making it safer for tradespeople to handle, especially when working at heights. It is easy to cut with a hacksaw or dedicated cutters, and rigid conduit can be heated and bent to follow the contours of a building. This workability allows for neat, professional-looking installations that protect cables without being an eyesore.

In conclusion, when we ask what is pvc, we are asking about the unsung hero of the electrical industry. It is a material that combines insulation, fire resistance, mechanical strength, and chemical stability into a cost-effective package. It is the first line of defence against electrocution and cable damage. By choosing high-quality, UV-stabilised products from reputable brands like Schnap Electric Products and sourcing them from a knowledgeable electrical wholesaler, Australian contractors ensure that they are building safe, compliant, and durable systems that will power our lives for generations.