Kingsgrove Branch:

Schnap Electric Products Blog

Schnap Electric Products Blog Posts

Magnetic Wire Puller

G'day! If you have ever tried to run a new data cable, speaker wire, or coaxial line behind a finished plasterboard wall, you know it can be an absolute nightmare. You drill your entry hole, shove the yellow tongue down, and then spend the next hour fishing around blindly with a coat hanger, trying to hook the cable while trying not to punch a hole in the Gyprock out of frustration. It is a classic renovation struggle, but there is a tool that turns this hard yakka into a five-minute job.

It is called a magnetic wire puller, and for anyone doing retrofits or cable management, it is worth its weight in gold. This clever system uses powerful rare-earth magnets to guide cables through wall cavities with pinpoint precision, saving your walls and your sanity.

How Does It Work?

The concept is brilliantly simple. A magnetic wire puller kit usually consists of two main parts: a leader magnet attached to a small eyelet, and a handheld roller unit with extremely strong magnets inside.

- You attach your cable to the leader magnet (the bit that goes inside the wall).

- You feed the leader into the wall cavity through a small hole.

- You place the handheld roller unit against the outside of the plasterboard.

- The magnets connect through the wall with a satisfying "clunk."

- You simply drag the roller unit along the wall, and the leader magnet follows it inside the cavity, pulling the cable right to your exit point.

Why It Beats the Old Methods

The traditional way of fishing cables often involves a lot of guesswork. Yellow tongues and draw wires are great for open spaces, but they get snagged on insulation, caught on noggins, or curl up in the wrong direction.

A magnetic wire puller gives you total control. You can literally trace the path of the cable down the wall. It allows you to navigate around obstacles and insulation batts that would usually stop a yellow tongue in its tracks. Because you are guiding it from the outside, you know exactly where the cable is at all times. This precision means you don't have to drill multiple "exploratory" holes to find your wire, which saves you a massive amount of time on patching and painting later.

Choosing the Right Tool

Not all magnets are created equal. Cheap online gadgets often have weak magnets that lose connection as soon as they hit a bit of thick plasterboard or insulation.

When a professional tradesperson visits an electrical wholesaler to buy tools, they look for a puller with high-strength magnets capable of pulling through 13mm or even 16mm plasterboard. They also look for a design that includes a non-marring surface on the roller to ensure it doesn't scuff the paintwork as it slides across the wall.

Important Safety and Usage Tips

While this tool is a lifesaver, you need to use it correctly.

- Watch Your Fingers: These are often neodymium magnets, and they snap together with serious force. Keep your fingers out of the way to avoid a nasty pinch.

- Avoid Metal Studs: If you are working in a commercial building with steel stud framing, the magnet will stick to the frame. You need to navigate carefully down the centre of the cavity.

- Know Your Limits: While running data, AV, or speaker cabling is generally safe for a competent DIYer, installing fixed 240V electrical wiring is strictly regulated. In Australia, fixed electrical work must be done by a licensed electrician.

Professional Tools from Schnap Electric

To get the job done quickly and without damaging your walls, you need a puller that holds fast. Using quality gear ensures the leader magnet doesn't drop off halfway down the wall, leaving you back at square one.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a wide range of installation tools, including high-performance magnetic wire puller kits designed to make cable fishing effortless. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric helps you run cables neatly, efficiently, and with minimal mess. For a smarter way to wire, check out the tool range at Schnap Electric.

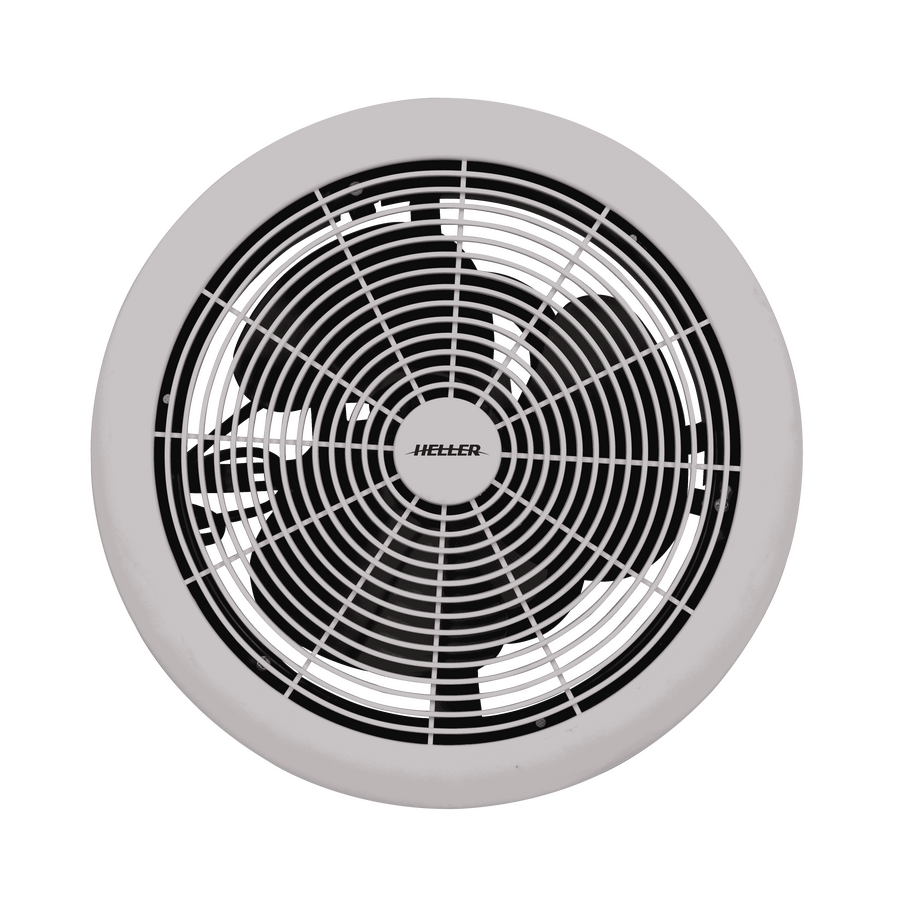

Kitchen Fan

G'day! The kitchen is undoubtedly the busiest room in any Aussie house. Whether you are searing a steak for a Friday night dinner or frying up bacon and eggs on a Sunday morning, cooking creates a lot of by-products. Smoke, steam, grease, and lingering odours can quickly turn a pleasant open-plan living area into a foggy, smelly mess. The unsung hero that keeps your home fresh and clean is the humble kitchen fan.

While we often focus on the oven or the benchtop during a renovation, ventilation is critical. Without adequate extraction, grease particles settle on your cabinets, making them sticky and hard to clean, while moisture from boiling pots can lead to mould growth on the ceiling.

Understanding Your Options

When it comes to moving air in the kitchen, you generally have two main categories to choose from: the dedicated rangehood and the ceiling-mounted exhaust fan.

The Rangehood This is the most common form of kitchen fan. It sits directly above your cooktop and is designed to capture smoke and steam at the source. They come in various styles, including slide-out (retractable), canopy, and undermount, to suit different cabinetry designs.

Ceiling Exhaust Fans For kitchens without a rangehood, or for older homes that need extra ventilation, a ceiling-mounted exhaust fan is a great solution. These units are similar to bathroom fans but often have higher motor power to deal with the density of cooking fumes. They are particularly useful in large, open-plan kitchens where a rangehood might struggle to clear the entire room.

Ducted vs Recirculating

This is the big decision you need to make.

- Ducted: This is the gold standard. The fan sucks the air up and pushes it through a ducting pipe to the outside of your house (through the roof or wall). It physically removes the smoke, steam, and smells from the building.

- Recirculating: In some apartments or rentals, ducting to the outside isn't possible. A recirculating kitchen fan pulls the air through a carbon filter to clean it and then blows it back into the room. While better than nothing, it is less effective at removing heat and moisture.

Noise Levels and Performance

Nobody wants a fan that sounds like a jet engine taking off while they are trying to have a conversation over dinner. When choosing a unit, check the noise level rating (measured in decibels).

You also need to look at the airflow capacity. A large kitchen with a massive gas cooktop needs a powerful motor to be effective. Professional installers often visit a trusted electrical wholesaler to compare the specs of different motors, ensuring they get a unit that moves enough air without being deafeningly loud.

Installation and Safety

Installing a new fan often involves cutting holes in cabinetry or the ceiling and working with 240V mains power. This is strictly regulated work.

In Australia, you must engage a licensed electrician to install any hardwired ventilation equipment. They will ensure the unit is securely mounted and that the ducting is installed correctly to prevent back-drafts. A professional will also ensure the circuit can handle the load, keeping your home safe from electrical faults.

Quality Ventilation from Schnap Electric

To keep your kitchen clean and odour-free, you need extraction gear that is built to last. Cheap fans with plastic motors often rattle and fail after a few years of exposure to heat and grease.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of ventilation solutions, including high-performance kitchen fan models and heavy-duty exhaust units. Their inventory also includes the essential ducting, grilles, and mounting accessories required for a complete install. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your kitchen remains the fresh, welcoming heart of your home. For ventilation that works as hard as you do, check out the range at Schnap Electric.

Kitchen Fan Exhaust

G'day! We all love a good cook-up, whether it is searing a steak on the stovetop or roasting a leg of lamb for Sunday lunch. However, the lingering smells, airborne grease, and steam can quickly turn your open-plan living area into an uncomfortable environment. If your smoke alarm goes off every time you cook toast, it is a clear sign that your ventilation needs an upgrade. The most effective way to maintain air quality and protect your cabinetry from grime is by installing a high-quality kitchen fan exhaust.

While many people focus on the aesthetics of their kitchen renovation, ventilation is the engine room that keeps the space functional. Without proper extraction, moisture can lead to mould on the ceiling, and grease can coat your expensive joinery in a sticky film that is a nightmare to clean.

How Does It Work?

A kitchen fan exhaust system works by using a motorized fan to pull air from the cooking area. It draws the air through a set of filters designed to trap grease particles before they enter the motor or ducting.

The most common form is the rangehood, which sits directly above the cooktop. However, in some kitchen designs or older homes, a ceiling-mounted exhaust fan is used to clear the general room air. The goal is to create negative pressure, sucking the polluted air out and allowing fresh air to circulate.

Ducted vs Recirculating: The Big Decision

When selecting a system, you have two main options regarding where the air goes.

Ducted Systems This is the gold standard for Australian homes. A ducted kitchen fan exhaust connects to piping that runs through the ceiling cavity or wall to the outside of the house. It physically removes the smoke, steam, and odours from the building. It is far more efficient and quieter than the alternative.

Recirculating Systems In apartments or multi-storey homes where ducting to the outside is impossible, recirculating models are used. These pull the air through a charcoal filter to neutralise odours before blowing the air back into the kitchen. While they help with smells, they do not remove heat or moisture.

Choosing the Right Capacity

Size matters when it comes to moving air. If you have a large 900mm gas cooktop, a small, underpowered fan simply won't cope with the volume of smoke produced.

You need to look at the airflow rating, measured in cubic metres per hour (m3/hr). A standard kitchen might need 600 m3/hr, while a heavy-duty setup for a keen chef might require 1000 m3/hr or more. When planning this, professional installers often visit a trusted electrical wholesaler to compare motor specs and noise levels, ensuring the unit is powerful enough to do the job without sounding like a jet engine.

Installation and Safety

Installing extraction fans is not a simple DIY task. It involves cutting holes in cabinetry or gyprock, running ducting, and connecting to 240V mains power.

In Australia, any fixed electrical work must be carried out by a licensed electrician. They will ensure the fan is mounted securely and that the electrical circuit can handle the load. Improper installation can lead to vibration noise, back-drafts, or even fire hazards if grease builds up in the wiring. A qualified tradesperson ensures your system is compliant with local building codes.

Superior Ventilation from Schnap Electric

To keep your kitchen pristine, you need reliable equipment that can handle the heat and grease of daily cooking. Cheap plastic fans often degrade quickly and lose suction power.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of ventilation solutions, including high-performance kitchen fan exhaust units, heavy-duty motors, and all the necessary ducting accessories. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your kitchen remains fresh, clean, and safe. For ventilation solutions that really work, trust the quality range from Schnap Electric.

Hybrid Inverter

G'day! Australia is currently in the middle of a rooftop solar boom. With electricity prices soaring, households across the country are looking for ways to become more self-sufficient and reduce their reliance on the grid. While standard solar systems are fantastic for offsetting daytime usage, they have a major limitation: they cannot store energy for the evening. This is where the hybrid inverter steps in as a game-changer for the modern Aussie home.

This intelligent device is the next evolution in solar technology. It combines the functionality of a standard solar inverter with a battery inverter, all in one neat unit. By allowing you to store excess solar energy during the day and use it at night, a hybrid system helps you squeeze every last drop of value out of your panels.

How Does a Hybrid System Work?

To understand the value of a hybrid inverter, you first need to understand the flow of energy. In a traditional setup, your solar panels generate DC electricity, which the inverter converts to AC electricity for your home. If you don't use that power immediately, it is sent back to the electricity grid for a small feed-in tariff.

A hybrid unit changes this process. Instead of sending that valuable excess power to the grid, it directs it into a battery bank.

- Daytime: The system powers your home with solar energy and uses any surplus to charge the battery.

- Evening: When the sun goes down and energy rates are often highest, the inverter draws power from the battery to run your lights, TV, and appliances.

- Grid Interaction: Only when the battery is empty does the system draw from the grid. Conversely, if the battery is full, it can still export to the grid.

Why Make the Switch?

Maximise Self-Consumption The gap between what you pay for electricity and what retailers pay you for your solar export is widening. It makes financial sense to use as much of your own generated power as possible. A hybrid inverter automates this process, ensuring you are self-powered for longer periods of the day.

Blackout Protection One of the biggest misconceptions about standard solar is that it works during a blackout. It doesn't. For safety reasons, standard inverters shut down when the grid fails. A hybrid system, however, can be configured to isolate your home from the grid and continue running essential circuits off battery power, keeping the lights on and the fridge cold during a storm.

Future-Ready Even if you aren't ready to buy a battery today, installing a "battery-ready" hybrid unit now saves you money later. When you do decide to add storage, you won't need to buy a second inverter or replace your existing hardware; you simply plug the battery in.

Installation and Compliance

Installing a solar and battery system is complex work involving high-voltage DC electricity. This is strictly regulated in Australia to prevent fire risks and ensure grid stability.

You must engage a licensed electrician with Clean Energy Council accreditation to install a hybrid inverter. A professional installer will assess your energy needs and ensure the system is sized correctly. They will typically visit a trusted electrical wholesaler to source high-quality cabling, DC isolators, and circuit protection that meet Australian Standards. Using trade-grade components is vital for the longevity and safety of the system, especially given the harsh Australian climate.

Powering Your Future with Schnap Electric

When you are investing in energy independence, you need components that are built to perform. A cheap inverter or faulty switchgear can compromise the efficiency of your entire setup.

Schnap Electric Products is a premier supplier for the trade industry in Australia. They stock a comprehensive range of solar and battery installation gear, including heavy-duty DC isolators, battery cabling, and robust circuit protection designed for hybrid systems. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your move to battery storage is safe, compliant, and efficient. For the best in solar infrastructure, trust the range from Schnap Electric.

Hybrid Inverter Solar

G'day! There is no denying that Australians have embraced renewable energy with open arms. Rooftop panels are now a standard sight in suburbs from Brisbane to Perth. However, the traditional solar setup has always had one major flaw: if the sun isn't shining, you are paying for power. To bridge the gap between daytime generation and evening consumption, more households are turning to hybrid inverter solar technology.

This advanced system is the key to unlocking true energy independence. By allowing you to easily integrate a battery into your solar array, a hybrid setup ensures you can use your own green energy long after the sun has set, protecting you from rising grid prices and unexpected blackouts.

How It Changes the Game

A standard solar system uses a "grid-tie" inverter. Its job is simple: convert the energy from the panels into usable power for your home and send the excess to the grid. If you want to add a battery later, you often need to buy a second, separate inverter just for the battery, which adds cost and complexity.

A hybrid inverter solar system streamlines this process. It combines the solar inverter and the battery inverter into one sophisticated unit. It manages the flow of electricity between your solar panels, your home appliances, the battery bank, and the main electricity grid simultaneously. It is the brain of a modern, self-sufficient home.

The Benefits of Storage Integration

Slash Your Evening Bills Most households use the bulk of their electricity in the morning and evening—times when solar production is low or non-existent. A hybrid system stores the surplus energy generated during the midday peak. Instead of selling it to the retailer for a few cents, you store it and use it to run the TV, lights, and dishwasher at night for free.

Energy Security Australian weather can be unpredictable. In a standard solar setup, if the grid goes down, your solar turns off for safety reasons. A hybrid inverter solar system can be configured to provide backup power. It detects the grid failure, isolates your home from the street, and keeps essential circuits running off the battery.

Smart Management These units are highly intelligent. They can be programmed to charge the battery from the grid during off-peak times when rates are cheap and discharge it during peak times, saving you money even on cloudy days.

Professional Installation is Mandatory

It is important to understand that installing a hybrid system is a significant electrical undertaking. It involves integrating high-voltage DC from the roof, high-current DC from the batteries, and AC connections to the grid.

In Australia, this work must be performed by a licensed professional with Clean Energy Council accreditation. You cannot attempt any part of this installation yourself. A qualified installer understands the complexities of load balancing and safety isolation. When planning the build, they will typically source the necessary switchgear, heavy-duty cables, and safety labels from a reputable electrical wholesaler to ensure every component complies with AS/NZS standards. Using trade-quality gear is essential for the longevity and safety of the system.

Building a Robust System with Schnap Electric

A hybrid setup is a long-term investment in your property value and lifestyle. To get the best return on investment, you need to ensure the supporting infrastructure is up to the task.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of solar installation components designed to support hybrid inverter solar systems. Their inventory includes UV-stabilised DC isolators, battery cabling, and circuit protection devices that are built to withstand the harsh Australian climate. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your path to energy freedom is safe, reliable, and built to last. For the best in solar infrastructure, trust the range from Schnap Electric.

Contactor

G'day! In the world of electrical control, there are standard light switches, and then there are the heavyweights. When you need to switch high-power loads like large motors, banks of floodlights, or industrial heating elements, a standard plastic wall switch simply isn't up to the task. It would melt under the pressure. To handle these high-current applications safely and remotely, the industry relies on a device known as a contactor.

This robust component is the backbone of automation and industrial control. Whether you are running a commercial air conditioning plant or a simple pool pump timer, understanding the role of this device is key to maintaining a reliable electrical system.

What is a Contactor?

Think of a contactor as a massive, remote-controlled switch. It is an electrically controlled switch used for switching an electrical power circuit. While it operates on a similar principle to a relay, it is designed for much higher current ratings.

It allows a low-power circuit (like a 24-volt control signal from a timer or sensor) to switch a high-power circuit (like a 415-volt motor) on and off. This separation of control power and load power is crucial for safety, as it keeps the operator well away from the dangerous high voltages required to run heavy machinery.

How Does It Work?

Inside the unit, there is an electromagnetic coil. When a small current is sent to this coil, it creates a magnetic field that pulls a set of heavy-duty contacts together. Snap! The circuit closes, and power flows to the motor or lights. When the control current stops, a spring forces the contacts apart, breaking the circuit and stopping the machine.

This mechanism is designed to open and close quickly to suppress the electrical arc that occurs when switching heavy loads. This arc suppression is what stops the switch from welding itself shut or burning out, which is what would happen if you tried to use a standard switch for a high-current job.

Where Are They Used?

You will find these devices everywhere in the Australian landscape, from residential homes to massive mining sites.

Motor Control This is the most common application. From swimming pool pumps to conveyor belts, a contactor is essential for starting and stopping electric motors safely.

Lighting Control In commercial buildings or sports fields, you often have banks of high-powered lights. Rather than running thick cables to a wall switch, a contactor allows the entire system to be controlled by a simple timer or a smart building management system.

Heating and Cooling Large HVAC systems and industrial heaters draw significant power. These devices ensure that thermostats can turn these heavy loads on and off without being fried by the current.

Sourcing the Right Component

Not all switching devices are created equal. They are rated by the amount of current (Amps) they can handle and the type of load they are switching (resistive vs inductive).

When a professional installer visits an electrical wholesaler to pick up parts for a job, they need to match the specifications exactly. Using an undersized unit for a motor with a high startup current will lead to premature failure and potentially dangerous overheating. It is vital to use trade-quality gear that meets Australian Standards for safety and durability.

Installation Safety

It is important to be absolutely clear: installing or replacing a contactor is not a DIY task. These devices usually handle dangerous voltages, often 415V three-phase power.

In Australia, fixed wiring work must be performed by a licensed electrician. A professional will ensure the device is mounted correctly in an enclosure, that the coil voltage matches the control circuit, and that the overload protection is calibrated correctly. Attempting this work yourself poses a severe risk of electrocution and fire.

Industrial Solutions from Schnap Electric

If you are managing high-power circuits, you need components that won't let you down when the pressure is on.

Schnap Electric Products is a premier supplier for the trade industry in Australia. They stock a comprehensive range of industrial switchgear, including high-performance contactor units in various pole configurations and amperage ratings. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your machinery and lighting systems operate reliably and safely. Whether you are automating a pump or refitting a factory, trust the industrial range from Schnap Electric.

Electrical Contactor

G'day! In the world of domestic wiring, a standard light switch does the job perfectly fine. However, when you step up to commercial or industrial environments where heavy machinery and high-voltage systems are the norm, a simple plastic switch would melt in seconds. To handle the hard yakka of switching high-power circuits safely and remotely, the industry relies on a robust device known as an electrical contactor.

This component is the backbone of automation, heating, and motor control across Australia. Whether you are running a large irrigation pump on a farm or controlling the lighting banks at a local footy oval, understanding how this device works is essential for maintaining a reliable and safe electrical system.

What is an Electrical Contactor?

An electrical contactor is essentially a high-capacity relay. It is an electrically controlled switch used for switching an electrical power circuit. While a standard relay is typically used for low-current applications (like dashboard lights in a car), a contactor is designed to handle significantly higher current loads, ranging from 10 Amps right up to thousands of Amps.

The primary function is to allow a low-power control circuit (like a 24-volt timer or a push-button) to switch a high-power load (like a 415-volt motor) on and off. This separation of the control circuit from the load circuit is a critical safety feature, ensuring operators are not exposed to dangerous high voltages when starting or stopping machinery.

How It Works

The mechanism inside is ingenious yet simple. It consists of a coil, a stationary iron core, and movable contacts. When a control voltage is applied to the coil, it creates a magnetic field. This magnet pulls the contacts together with significant force, closing the circuit and allowing power to flow to the motor or lights.

When the control voltage is removed, a spring forces the contacts apart, breaking the circuit immediately. This rapid "snap" action is vital. It helps suppress the electrical arc that naturally occurs when switching heavy loads, preventing the contacts from welding shut and ensuring a long service life.

Common Applications in Australia

Motor Starters This is the most common use. From air conditioning compressors to industrial conveyor belts, almost every large electric motor utilises an electrical contactor to start and stop.

Lighting Control For large commercial buildings or retail spaces, turning on hundreds of lights individually is impractical. Contactors allow entire floors or zones to be controlled by a single automated system or timer.

Heating Evaporators In industrial processes, large heating elements require massive amounts of power. Contactors regulate this flow to maintain precise temperatures without burning out the control switches.

Choosing the Right Unit

Not all contactors are built the same. They are rated by the load they can handle (Amps) and the type of duty they perform (e.g., AC-3 for motors or AC-1 for heating).

When a professional contractor is planning a job, they will head to a trusted electrical wholesaler to source specific components that match the application. Using an undersized unit for a motor with a high start-up current will lead to rapid failure, overheating, and potentially expensive downtime. It is vital to use trade-quality gear that is rated for Australian conditions and standards.

Installation Safety

It is critical to understand that installing or replacing an electrical contactor is not a task for the home handyman. These devices sit at the heart of high-voltage systems, often dealing with 415V three-phase power.

In Australia, strictly enforced regulations state that any fixed wiring work must be performed by a licensed electrician. A qualified professional will ensure the coil voltage is correct, the thermal overload protection is calibrated, and the unit is mounted securely within a compliant enclosure. Attempting this work without a licence is illegal and poses a severe risk of electrocution and fire.

Industrial Strength Solutions from Schnap Electric

For high-power applications, reliability is everything. You need components that can handle millions of switching cycles without skipping a beat.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of industrial control gear, including high-performance electrical contactor units suitable for everything from HVAC systems to heavy machinery. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your critical infrastructure operates safely and efficiently. Whether you are building a new control panel or maintaining existing plant equipment, trust the industrial range from Schnap Electric.

Socket Holder

G'day! There is a universal truth in every workshop and shed across Australia: the 10mm socket will always go missing exactly when you need it most. Whether you are fixing the ute, assembling a new workbench, or maintaining industrial machinery, scrambling around in the bottom of a tool bag for the right size attachment is a waste of time and patience. To keep your gear organised and your workflow smooth, you need a quality socket holder.

This simple storage solution is the difference between a professional, efficient setup and a disorganized mess. By keeping your sockets lined up by size and drive type, you can see instantly if a piece is missing before you pack up for the day, saving you a fortune in replacement costs over the long run.

Different Styles for Different Jobs

Not all storage solutions are built the same. Depending on whether you work out of a mobile van or a fixed workshop, the right socket holder for you will vary.

Socket Rails These are the classic choice. They consist of a metal or plastic strip with spring-loaded clips that the sockets snap onto. They are slim, lightweight, and perfect for throwing into a portable tool bag.

Magnetic Holders For those with a large metal tool chest, magnetic holders are brilliant. They hold the sockets firmly in place using strong magnets, allowing you to stick the entire holder to the side of a hoist, the wall of a shed, or the lid of your toolbox. They are great for quick access during a job.

Tray Organisers These are often found in the drawers of professional mechanics. They feature marked posts for every specific size (metric and imperial). While they take up more space, they make it impossible to put a socket back in the wrong spot.

Managing Drive Sizes

When setting up your organisation system, you need to match the holder to your drive size. Most Australian kits come in three standard drive sizes: 1/4-inch, 3/8-inch, and 1/2-inch.

Attempting to force a 1/2-inch drive socket onto a 1/4-inch clip will just result in broken plastic. A good socket holder set will usually come with interchangeable clips or separate rails for each drive size, ensuring your heavy-duty impact sockets and your delicate precision sockets are stored securely and separately.

Professional Standards and Tools

While it might seem like a basic accessory, the quality of your tool storage matters. Cheap plastic rails become brittle in the cold or melt in the heat of a ute canopy. Professional tradespeople know that investing in robust organisation systems saves time on the job site.

When stocking up on essential workshop consumables and tools, many tradespeople visit a dedicated electrical wholesaler to find gear that is built to trade standards. They look for holders made from high-impact materials or anodised aluminium that can withstand being dropped on concrete or rattled around in the back of a truck on a corrugated road.

Get Organised with Schnap Electric

If you want to stop losing tools and start working more efficiently, you need storage solutions that work as hard as you do. A tidy workspace is a safe and productive workspace.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of tool storage and installation accessories, including robust socket holder options designed to keep your kit in order. By providing the same professional-grade equipment and tools you would expect to find at a major electrical wholesaler, Schnap Electric ensures your workshop is organised, compliant, and ready for any project. For a shed that looks as good as the work you produce, check out the range at Schnap Electric.

Cable Locator

G'day! Whether you are putting in a new fence, digging a trench for a pool, or excavating for a new driveway, breaking ground is always a bit of a gamble if you don't know what is underneath. Hitting a water pipe is messy and expensive, but hitting a live mains power line can be fatal. This is why a high-quality cable locator is an essential piece of equipment for any tradesperson or serious renovator doing earthworks.

Gone are the days of relying solely on rough maps and guesswork. Modern locating technology allows you to pinpoint exactly where utilities are buried, how deep they are, and which direction they are running. It turns a dangerous guessing game into a precise, safe operation.

How Does a Cable Locator Work?

A cable locator generally consists of two parts: a transmitter and a receiver.

The Transmitter: This box sends a signal down a cable or pipe. It can do this by direct connection (clipping onto the pipe) or by induction (placing the box on the ground above the suspected utility).

The Receiver: This is the handheld wand you walk around with. It picks up the signal generated by the transmitter. As you sweep the area, the receiver gives you visual and audio feedback, beeping louder as you get closer to the buried service.

Advanced models can also detect "passive" signals. These are signals naturally radiating from live power cables or radio signals travelling along metal pipes, allowing you to find services without even hooking up the transmitter.

Why Relying on Plans Isn't Enough

You might have your "Dial Before You Dig" (DBYD) plans, and that is a great start. However, plans are not always accurate. Paths change, renovations happen, and sometimes the original installer just didn't follow the drawing.

A cable locator gives you the real-time truth of what is in the ground right now. It can save you from the "dog's breakfast" of a burst pipe or the massive cost of repairing a severed fibre optic cable. For professional excavators and plumbers, the cost of the tool is paid back the very first time it prevents a strike on a buried service.

Sourcing Professional Equipment

Not all locators are built the same. There is a big difference between a cheap stud finder and a rugged, industrial locating tool designed for civil works.

When a professional needs to upgrade their detection gear, they usually visit a specialist electrical wholesaler to find units that are robust, waterproof, and accurate to within a few centimetres. Trade-quality locators often feature depth estimation, which tells you not just where the cable is, but how far down you have to dig before you hit it. This level of detail is critical for safe excavation.

Safety First

Using a cable locator significantly reduces risk, but it does not eliminate it entirely. You should always pothole (dig carefully by hand) to visually verify the service once you have located it electronically.

Additionally, if you do find a cable that needs moving or repair, do not touch it. Working with underground power is strictly the domain of the supply authority or a licensed professional. Never attempt to repair a damaged underground cable yourself.

Detect and Protect with Schnap Electric

If you are in the business of digging, you need gear that gives you confidence in every scoop of the shovel. Guesswork is not an option when safety is on the line.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a range of site safety and detection equipment, including high-precision cable locator kits suitable for finding power, data, and metal pipes. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your excavation projects proceed safely and without costly interruptions. Before you break ground, make sure you have the right detection gear from Schnap Electric.

Pipe and Cable Locator

G'day! Whether you are fencing a paddock, putting in a pool, or trenching for a new shed, breaking ground in Australia comes with significant risks. Beneath our feet lies a complex web of water pipes, gas lines, data cables, and high-voltage power lines. Striking one of these services isn't just an expensive mistake that can blow your budget; it can be a fatal error. This is why a professional pipe and cable locator is a non-negotiable piece of equipment for anyone serious about excavation safety.

While calling "Dial Before You Dig" is the first step, the plans provided are often just a guide. They might tell you a cable is in the vicinity, but they won't tell you exactly where it is or how deep it is buried. To ensure you are digging in the clear, you need precise, real-time data that only a dedicated locator tool can provide.

How Does the Technology Work?

A modern pipe and cable locator system is far more advanced than a simple metal detector. It typically uses a two-piece system consisting of a transmitter and a receiver to identify conductive materials underground.

Active Locating This is the most accurate method. The user connects the transmitter unit to an accessible point of the utility (like a riser pipe or a cable end) or places it on the ground above the suspected path. The transmitter sends a specific frequency signal along the pipe or cable. The handheld receiver is then used to trace this signal, giving the operator the exact line and often the depth of the utility.

Passive Locating Even without the transmitter, the receiver unit can often detect "passive" signals. These are electromagnetic fields naturally radiating from live power cables or radio signals that have been picked up and re-radiated by long metal pipes. This mode is excellent for sweeping a site to find unknown hazards before digging begins.

Why Accuracy Saves Money

The cost of repairing a severed fibre optic cable or a burst water main can run into the thousands, not to mention the downtime on your project while you wait for repairs. Using a pipe and cable locator acts as an insurance policy for your profit margin.

It allows for "potholing" or non-destructive digging. Once you have marked the location of the services with paint, you can carefully dig by hand to expose the utility without damaging it. This precision allows heavy machinery to work confidently around the hazard without the constant fear of a strike.

Choosing the Right Equipment

For tradespeople and contractors, durability is key. These tools live in the back of utes and get used in muddy, dusty environments.

When a professional is looking to upgrade their detection capabilities, they often visit a specialist electrical wholesaler to find units that are rugged, waterproof, and simple to operate. They look for features like multiple frequency modes, which allow the user to adjust the signal to suit different soil types and utility materials, ensuring a clear reading even in congested underground networks.

Safety is the Priority

It is important to remember that while technology is a massive help, there is no substitute for caution. Always treat every signal as a live, dangerous service until proven otherwise.

If you do locate an underground power cable that needs to be moved or worked around, this is strictly a job for the experts. You must engage the asset owner or a licensed professional to handle the infrastructure safely. Never attempt to move or repair underground utilities yourself.

Site Safety with Schnap Electric

If you are managing an excavation project, you need equipment that delivers accurate results every time. Guesswork is simply not an option when lives and livelihoods are on the line.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of site safety and detection equipment, including high-precision pipe and cable locator kits designed for the rugged Australian environment. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures you have the tools to map out your site effectively and dig with confidence. Before you start your next earthworks project, check out the detection range at Schnap Electric.