Kingsgrove Branch:

Schnap Electric Products Blog

Schnap Electric Products Blog Posts

Digital Tape Measure

In the high-cost, high-efficiency environment of the Australian construction and engineering sectors, the optimisation of workflow is a constant operational imperative. Traditional analogue methods of linear measurement, while reliable for short-range fabrication, present significant limitations regarding speed, safety, and data integration when applied to large-scale site estimation. The emergence of the digital tape measure—technically classified as the Laser Distance Meter (LDM)—has revolutionised the way trade professionals acquire spatial data. For project managers, electrical contractors, and quantity surveyors, transitioning from mechanical tapes to optoelectronic measurement systems is not merely a matter of convenience; it is a strategic move to reduce labour costs and eliminate human error in the quantification of materials.

The Physics of Optoelectronic Measurement

To understand the reliability of these devices, one must appreciate the underlying physics. Unlike a mechanical tape which relies on physical extension, a digital laser measure typically operates on the phase-shift principle. The device emits a modulated laser beam (usually Class 2, <1mW) towards a target surface.

When the laser light reflects off the target and returns to the device’s receiving aperture, the internal processor analyses the phase shift between the transmitted and received waveforms. This phase difference is directly proportional to the distance travelled. This method allows for exceptional accuracy, often within ±1.5mm over a distance of 100 metres. This level of precision is critical when ordering high-cost infrastructure materials, such as heavy-duty mains cabling or custom-fabricated ductwork, where over-ordering creates waste and under-ordering causes costly project delays.

Operational Efficiency and One-Person Workflow

The primary economic driver for the adoption of digital measurement tools is the reduction in labour requirements. Measuring a 30-metre warehouse span with a traditional steel tape is a two-person task: one to hold the zero end and one to read the measurement, often requiring a scissor lift to clear obstacles.

With a digital device, this becomes a rapid, one-person operation. The operator simply places the device against the reference wall and targets the opposing surface. The measurement is instantaneous. This capability is particularly valuable for quoting and estimating. A contractor can walk a site and generate a complete bill of materials for conduit and cabling in a fraction of the time required by traditional methods. When sourcing supplies from an electrical wholesaler, the ability to provide exact lengths rather than rough estimates allows for more accurate budgeting and reduces the volume of scrap copper left on the site floor.

Indirect Measurement and Pythagorean Logic

A distinct technical advantage of digital units is the integration of algorithmic functions, specifically the Pythagorean mode. This allows for the indirect measurement of height or width where direct line-of-sight is obstructed or where physical access is dangerous.

For example, measuring the height of a cable tray suspended in a high ceiling void would traditionally require a ladder or platform. Using the Pythagorean function, the operator stands at a distance, measures the hypotenuse (distance to the top of the tray) and the base (distance to the wall below the tray). The internal processor then calculates the vertical height using the Pythagorean theorem ($a^2 + b^2 = c^2$). This feature significantly enhances site safety by keeping boots on the ground and reducing the frequency of working-at-heights incidents, a key focus of Safe Work Australia protocols.

Data Integration and BIM Connectivity

The modern construction site is data-driven. Advanced digital measures now feature Bluetooth connectivity, allowing them to interface directly with smartphones and tablets running CAD or Building Information Modelling (BIM) software.

This "scan-to-plan" workflow eliminates the transcription errors that frequently occur when jotting down measurements in a notebook. Dimensions are transferred directly into the digital plan, creating an instant, as-built record. For electrical engineers designing complex reticulation systems, this means that the physical reality of the site can be mapped into the digital twin with millimetre precision.

Durability and Ingress Protection

Given the harsh nature of Australian worksites, delicate electronics are often viewed with scepticism. However, professional-grade digital measures are engineered with robust Ingress Protection (IP) ratings, typically IP54 or IP65. This ensures resistance to the pervasive dust of a building site and protection against water spray.

The housing is usually constructed from impact-resistant ABS with a rubberised over-mould to withstand drops onto concrete. When selecting tools, professionals should look for units that have been drop-tested to at least one metre. This ruggedness allows the tool to survive in the same tool bag as heavy-duty hardware.

Application in Electrical Infrastructure

For the electrical trade, the digital measure is indispensable for planning cable routes. When calculating the linear meterage for a long run of Schnap Electric Products flexible conduit or determining the requisite length of cable ladder, the laser measure cuts through the clutter of a busy site.

Furthermore, accurate measurement is vital for voltage drop calculations. A precise distance reading ensures that the cable cross-section selected is adequate for the run length, maintaining compliance with AS/NZS 3000. It also aids in the precise ordering of protection mechanics. If a contractor needs to install Schnap Electric Products cable cover strips over a specific length of underground trench, the laser measure ensures that the quantity ordered covers the trench perfectly without the need for excessive joining or cutting.

Conclusion

The digital tape measure represents the convergence of metrology and information technology. It transforms the physical act of measuring into a digital data point, ready for integration into the complex logistics of modern construction. By leveraging the accuracy of laser physics, utilizing indirect measurement algorithms to enhance safety, and integrating these tools with robust materials from trusted brands like Schnap Electric Products, industry professionals can achieve a level of precision and efficiency that traditional methods simply cannot match. In the science of estimation, the laser provides the definitive answer.

Underground Warning Tape

In the dense and complex web of Australian civil infrastructure, the protection of sub-surface utilities is a critical engineering priority. The vast network of power cables, telecommunication ducts, gas mains, and water pipes that underpins modern society faces a constant threat from mechanical excavation. The "dial before you dig" initiative is the administrative control, but the physical engineering control—the final barrier between a hydraulic excavator bucket and a high-voltage cable—is the underground warning tape. For civil engineers, project managers, and safety officers, viewing this product merely as a coloured plastic strip is a fundamental error. It is a regulated safety device governed by Australian Standard AS/NZS 2648.1, designed to provide a visual warning and, in specific configurations, a detectable signal to prevent catastrophic asset failure and safeguard human life.

The Regulatory Framework: AS/NZS 2648.1

The application of underground marking is not arbitrary; it is strictly codified. AS/NZS 2648.1 (Underground marking tape - Non-detectable tape) sets the baseline for colour coding and material performance. The efficacy of the system relies on universal recognition of the hazard type based on the tape colour.

- Orange: Strictly reserved for electrical services.

- White: Designated for telecommunications and data conduits.

- Yellow: Indicates gas reticulation and petroleum pipelines.

- Green: Used for water mains and sewage infrastructure.

Deploying the incorrect colour is a compliance breach that introduces significant liability. If a contractor uncovers a green tape and assumes it is a water pipe, only to strike a gas main, the consequences are severe. Therefore, maintaining a strictly segregated inventory is essential. When procuring site consumables from a specialised electrical wholesaler, project managers must ensure that the specific AS-compliant text (e.g., "DANGER BURIED ELECTRICAL CABLE") is printed clearly on the substrate.

Material Science: Chemical Resistance and Soil Ph

The operational environment for these tapes is chemically hostile. Australian soils vary wildly, from the highly acidic sulphate soils of coastal regions to the alkaline clays of the interior. A standard packaging tape would degrade and disintegrate within months of burial.

Professional-grade warning tapes are manufactured from virgin Low-Density Polyethylene (LDPE). This polymer is selected for its chemical inertness. It is resistant to acids, alkalis, and soil bacteria that cause rot. However, the durability of the base material is only half the equation; the ink must also survive. Schnap Electric Products underground tapes utilise a lead-free, chemically bonded pigment system. This ensures that the warning text remains legible for the service life of the buried asset, often exceeding fifty years. If the text fades or the tape fragments, the warning is lost, rendering the safety measure void.

The Physics of Detection: Tracer Wire Technology

A significant limitation of standard polyethylene tape is that it is non-conductive. It cannot be found from the surface using standard electromagnetic cable avoidance tools (CATs). This presents a challenge for non-conductive assets like PVC water pipes or fibre optic ducts.

To bridge this gap, "Detectable" tape is employed. This composite material incorporates a conductive element, typically a sinusoidal stainless steel wires woven into the mesh or laminated between polyethylene layers. This allows a service locator to attach a signal generator to the termination point of the tape, inducing a signal that can be tracked from the surface. The selection of stainless steel (grade 304 or 316) over copper or aluminium is critical for corrosion resistance. Schnap Electric Products detectable tapes are engineered to maintain continuity even if the tape is stretched during backfilling, ensuring that the locating signal is not broken.

Installation Protocols: The Buffer Zone

The effectiveness of the warning system is heavily dependent on the depth of installation. The tape is not designed to be wrapped around the cable or pipe. It must be positioned in the "buffer zone" above the asset.

Engineering best practice typically dictates that the tape be installed approximately 300mm to 500mm directly above the utility. This vertical separation provides the excavator operator with a margin of error. When the bucket teeth catch the tape and pull it to the surface, the operator has time to cease digging before striking the asset below. Installing the tape too deep (directly on the cable) renders it useless, as the strike occurs simultaneously with the warning. Conversely, installing it too shallow risks it being removed during minor surface works or landscaping.

Elongation and Tensile Strength

Mechanically, the tape must possess specific physical properties to function correctly. It requires a high degree of elongation (stretch) before breaking.

When an excavator bucket catches the tape, it should stretch and lift out of the trench, becoming visible to the spotter or operator. If the tape is brittle and snaps instantly underground, it may not be noticed until it is too late. Schnap Electric Products tapes are engineered with a calculated elongation capability, allowing them to withstand the tensile stress of being pulled through compacted soil without immediate failure.

Procurement and Quality Assurance

Given the safety-critical nature of these products, the supply chain must be robust. Substandard imported tapes that lack UV stabilisation (for storage prior to burial) or use heavy-metal based inks pose environmental and safety risks.

Civil contractors and utility providers typically rely on a trusted electrical wholesaler to supply fully certified AS/NZS 2648.1 compliant products. Through this channel, they can access technical data sheets verifying the polymer thickness (typically 100 to 150 microns for premium grades) and the chemical resistance profile of the product.

Conclusion

The humble roll of underground tape is a silent sentinel in the civil engineering landscape. It lies dormant for decades, performing its function only in the split second before a potential disaster. Its performance relies on rigorous material science, strict adherence to colour standards, and correct installation depth. By utilising high-quality, chemically resistant, and detectable options from reputable brands like Schnap Electric Products, infrastructure owners can ensure that their buried assets remain protected and that future excavation teams are given the clear, unambiguous warning required to work safely. In the sub-surface world, visibility is the only defence.

Warning Tape

In the rigorous framework of Australian Work Health and Safety (WHS) legislation, the effective segregation of personnel from environmental hazards is a non-negotiable operational directive. While physical hard-barricading provides the ultimate separation, the immediate and tactical definition of exclusion zones relies heavily on visual communication tools. Industrial warning tape is the primary instrument for this purpose. Far from being a generic consumable, this polyethylene ribbon is a regulated safety device governed by strict Australian Standards regarding colour coding, UV stability, and tensile strength. For site managers, civil engineers, and safety officers, understanding the distinction between barrier tapes and underground marking tapes, as well as the compliance requirements of AS 1319 and AS 2648, is essential for mitigating liability and preventing catastrophic asset strikes.

The Hierarchy of Visual Communication: AS 1319

The efficacy of a hazard management system is predicated on universal recognition. In Australia, the colour and pattern of the tape convey specific instructions that must be instantly understood by all personnel entering a site.

- Yellow and Black Diagonal: This signifies "Caution." It is used for hazards where the risk is low to moderate, or where entry is permitted under controlled conditions. It is the standard for marking tripping hazards, overhead obstructions, or material storage perimeters.

- Red and White Diagonal: This signifies "Danger." It indicates a high-risk environment where entry is strictly prohibited for unauthorised personnel. This is mandatory for open excavations, live electrical testing zones, or areas where overhead lifting is in progress.

Using the incorrect colour is a compliance breach. A red and white tape used to mark a benign storage area dilutes the authority of the warning, potentially leading to complacency when real danger is present.

Underground Asset Protection: AS/NZS 2648.1

Beyond above-ground demarcation, a critical application of these products is the protection of buried infrastructure. AS/NZS 2648.1 (Underground marking tape) mandates specific colour codes to identify the nature of the utility below.

- Orange: Electrical services.

- White: Telecommunications and data.

- Yellow: Gas and petroleum.

- Green: Water and sewage.

The placement of this tape is a precise engineering control. It serves as a "buffer" warning. Best practice dictates that the tape be installed approximately 300mm to 500mm directly above the buried asset. When an excavator bucket penetrates the soil, it catches the tape first, alerting the operator to the presence of the utility before the asset itself is struck. When procuring these critical safety supplies from a specialised electrical wholesaler, project managers must verify that the tape carries the correct, legible warning text (e.g., "DANGER BURIED ELECTRICAL CABLE") printed with chemically resistant ink.

Material Science: UV Stability and Elongation

The physical environment of an Australian construction site is hostile to polymers. High levels of Ultraviolet (UV) radiation can rapidly degrade the molecular chains of low-quality plastics, causing them to photo-oxidise, become brittle, and fragment within days.

Professional-grade tapes are manufactured from virgin Low-Density Polyethylene (LDPE) masterbatches that incorporate specific UV stabilisers. The durability is also a function of thickness. A standard budget tape often lacks the tensile strength to withstand wind shear. Schnap Electric Products manufactures heavy-duty warning tapes engineered with a higher gauge to resist stretching and snapping. This ensures that the perimeter remains defined and taut, maintaining the integrity of the exclusion zone for the duration of the project.

Detectable vs. Non-Detectable Technologies

For non-conductive assets, such as PVC water pipes or fibre optic ducts, standard polyethylene tape offers visual warning but no detectability from the surface. To address this, "Detectable" warning tape is employed.

This composite product incorporates a stainless steel tracer wire woven into the mesh or laminated between the polymer layers. This conductive element allows service locators to attach a signal generator to the termination point and trace the path of the pipe from above ground using electromagnetic induction. The selection of marine-grade stainless steel is critical to prevent corrosion in acidic soils. Schnap Electric Products detectable tapes are designed to maintain electrical continuity even under the mechanical stress of backfilling, ensuring that the asset remains traceable for its entire service life.

Chemical Resistance in Sub-Surface Applications

Underground tapes face a chemical assault from the soil itself. Australian soil conditions range from the highly acidic to the highly alkaline. If the polymer or the printing ink is not chemically inert, the tape will degrade, rendering the warning illegible.

Schnap Electric Products underground tapes utilise lead-free, chemically bonded pigments that resist attack from soil bacteria and acids. This ensures that even after decades of burial, the warning message remains clear. Furthermore, the tape is engineered with a specific "elongation at break" ratio. When an excavator bucket pulls the tape, it stretches significantly before snapping, increasing the likelihood that it will be seen by the spotter above the trench.

Conclusion

The deployment of barrier and marking tape is a fundamental component of the safety ecosystem. It is the visual language of the worksite, communicating risk and location without words. Whether defining a temporary danger zone on a high-rise slab or safeguarding a high-voltage feeder in a suburban trench, the quality of the tape reflects the safety culture of the organisation. By adhering to AS 1319 and AS 2648, prioritizing UV-stabilised and chemically resistant materials, and utilizing robust safety products from trusted brands like Schnap Electric Products, industry professionals can ensure that their warnings are seen, understood, and respected. In the prevention of accidents, visibility is the first line of defence.

Vinyl Tape

In the critical domain of Australian electrical engineering and infrastructure maintenance, the integrity of a termination or cable splice is frequently dependent on the material properties of the primary insulating medium. While often trivialised as a general-purpose consumable, professional-grade vinyl tape—technically known as plasticised Polyvinyl Chloride (PVC) tape—is a sophisticated engineering product designed to provide electrical isolation, mechanical protection, and mandatory circuit identification. From the main switchboards of commercial data centres in Melbourne to the solar inverters of remote microgrids in the Northern Territory, the failure of this barrier material can result in moisture ingress, dangerous tracking faults, and non-compliance with AS/NZS 3000 (The Wiring Rules). For electrical engineers, site supervisors, and licensed contractors, understanding the plasticiser chemistry, elongation metrics, and strict flammability standards associated with this product is essential for maintaining a safe operational environment.

The Material Science: Plasticisers and Viscoelasticity

The operational efficacy of the tape is defined by the symbiotic relationship between its backing and its adhesive system. The backing is constructed from a PVC film that has been modified with plasticisers to achieve a specific degree of flexibility and elasticity. This property is technically referred to as "elongation at break."

High-quality vinyl tapes typically exhibit an elongation capability of 150% to 250%. This viscoelastic nature allows the technician to apply tension during the wrapping process, creating a compressive force known as "elastic memory." This force binds the tape layers tightly to the conductor profile, creating a hermetic seal that resists moisture penetration. Conversely, inferior tapes with poor plasticiser formulations often suffer from migration, where the tape becomes brittle and cracks over time, or the adhesive turns into a slimy residue. Premium tapes utilise a non-corrosive, pressure-sensitive rubber-based adhesive. Unlike aggressive solvent acrylics which may react with cable jackets, rubber adhesives are chemically neutral to standard polyethylene and cross-linked polyethylene (XLPE) insulation, ensuring the long-term integrity of the cable sheath.

Regulatory Compliance and Phase Identification

In the Australian context, the application of vinyl insulation tape is strictly governed by the need for clear visual identification of active conductors. AS/NZS 3000 mandates specific colour codes to denote the function of every conductor within an installation.

- Red, White, and Blue: These are strictly reserved for the identification of the three active phases (L1, L2, L3) in multiphase systems.

- Black: exclusively used for the Neutral conductor.

- Green/Yellow: Reserved for the Protective Earth (PE) conductor.

The use of generic black tape to repair a red active conductor without supplementary colour coding is a direct violation of safety standards. Consequently, ensuring a reliable supply of UV-stabilised coloured tapes is a logistical priority. When restocking site consumables, a diligent project manager will typically visit a specialised electrical wholesaler to ensure that the tapes procured meet the colour-fastness requirements of Australian Standards. This ensures that a red phase marker applied on a rooftop isolator does not fade to a confusing shade of pink or white after exposure to the harsh Australian UV index.

Dielectric Strength and Application Protocols

The primary function of the tape is electrical insulation. The "dielectric strength" is the measure of the tape's ability to resist electrical breakdown, typically expressed in kilovolts per millimetre (kV/mm). A professional-grade roll will usually offer a breakdown voltage of approximately 8,000V to 10,000V per layer.

To replicate the insulation value of the original cable jacket, industry best practice dictates the "half-lap" application method. The technician wraps the tape by overlapping the previous turn by exactly 50% of the tape’s width. This effectively creates a double layer of insulation with every revolution, doubling the dielectric protection and mechanical cushioning. Furthermore, the termination of the wrap is critical. The final 50mm of the tape should be applied with zero tension. Stretching the tape right to the cut point introduces tensile stress that will eventually cause the end to lift or "flag," compromising the seal.

Environmental Durability and Fire Retardancy

The operating environment for electrical infrastructure in Australia is hostile. Tapes must withstand temperature extremes, from sub-zero conditions in alpine regions to ambient temperatures exceeding 45°C in industrial plant rooms.

Schnap Electric Products manufactures a range of heavy-duty vinyl tapes engineered specifically for these conditions. Their premium range is formulated to resist "telescoping" (where the roll deforms in high heat) and maintains flexibility in cold weather. Moreover, fire safety is paramount. In the event of a switchboard fire, the tape must not act as a wick that propagates the flame along the cable bundle. Schnap Electric Products tapes are tested to meet rigorous self-extinguishing standards, adding a layer of passive fire protection to the switchboard assembly.

Mechanical Protection and Looming

Beyond pure insulation, these tapes serve a vital mechanical role in "harnessing" or looming cables. In complex control panels, keeping wiring neat and organised is essential for thermal management and future fault finding.

Using Schnap Electric Products coloured vinyl tapes allows for the logical grouping of circuits (e.g., separating 24V DC control lines from 240V AC power lines). The mechanical strength of the PVC backing protects the underlying wire insulation from abrasion against sharp metal edges within the enclosure or cable tray. Additionally, the chemical resistance of the vinyl backing ensures that the tape protects the cabling from exposure to mild acids, alkalis, and oils often present in industrial manufacturing environments.

Conclusion

The humble roll of vinyl tape is, in reality, a high-specification engineering component that serves as the final seal on a termination and the primary visual indicator of circuit logic. Its effective deployment requires a holistic approach that considers the material science of the adhesive, strict adherence to AS/NZS colour protocols, and the use of proper wrapping techniques. By selecting high-quality, flame-retardant, and highly elastic tapes from trusted brands like Schnap Electric Products, industry professionals can ensure that their installations remain electrically secure, mechanically sound, and compliant for the entire service life of the asset. In the science of safety, the quality of the wrap defines the reliability of the connection.

Label Tape

In the complex and regulated ecosystem of Australian electrical and telecommunications infrastructure, the clarity of information is a critical safety control. While the physical installation of cabling and switchgear forms the backbone of a system, the "user interface" for maintenance personnel is the identification system. Far from being a mere administrative nicety, the application of industrial label tape is a mandatory requirement governed by strict standards, including AS/NZS 3000 (The Wiring Rules) and AS/NZS 3080 (Telecommunications). For facility managers, network engineers, and electrical contractors, distinguishing between standard office stationery and engineered thermal transfer labelling media is essential for ensuring that critical asset data remains legible for the service life of the installation.

The Physics of Thermal Transfer Technology

To understand the durability of industrial labels, one must appreciate the printing mechanism. Unlike direct thermal printing (common in shipping labels and receipts), which relies on heat-sensitive paper that fades rapidly under UV exposure, professional labelling systems utilise thermal transfer technology.

In this process, a heated print head melts a resin-based ink from a ribbon directly onto the label substrate. In premium laminated tapes, this printing occurs on the underside of a clear protective laminate layer, which is then fused to the base colour layer. This "sandwich" construction encapsulates the text, rendering it virtually immune to abrasion, chemical attack, or fading. This technical distinction is vital for industrial environments where panels may be wiped down with aggressive solvents or exposed to the harsh Australian sun.

Adhesive Chemistry and Surface Energy

The performance of the tape is largely dictated by its adhesive formulation and the "surface energy" of the substrate. Not all surfaces are equal. A powder-coated switchboard door has different adhesion characteristics compared to a curved PVC cable jacket.

- Standard Adhesive: Designed for flat, smooth surfaces with high surface energy, such as stainless steel or glass.

- Flexible ID Adhesive: This is critical for cable marking. When a label is wrapped around a tight radius (like a Cat6A patch lead), the elastic memory of the plastic attempts to straighten it out, causing the label to uncurl or "flag." Flexible identification tape uses a specialised softer laminate and a more aggressive adhesive designed to bond to itself and textured plastics, ensuring the wrap remains secure.

Regulatory Compliance: AS/NZS 3000 Requirements

Under Australian Standards, the ambiguity of a circuit's function is a non-compliance risk. AS/NZS 3000 explicitly mandates that "all distinct circuit openings" must be legible and durable. This extends beyond the main switchboard to the field devices.

Handwritten markings on masking tape are not considered "durable" under the standard. They fade, smudge, and peel. A printed, laminated label provides a permanent record of the Circuit ID, the RCD rating, and the equipment function. For solar installations, specific UV-stable warning labels are required to identify DC isolators and high-voltage conduits. The use of yellow-and-black or red-and-white warning tapes produced by these digital printers allows contractors to generate custom safety signage on-demand that meets the specific hazard dimensions of the site.

Infrastructure Integration and Cable Management

The application of labels often requires integration with physical support infrastructure. A label cannot always be applied directly to a component if the surface area is too small or irregular.

This is where the integration of Schnap Electric Products becomes essential. Schnap Electric Products manufactures a range of identification cable ties and tag holders designed to act as a substrate for label tape. By applying the printed tape to a Schnap Electric Products flat-head marker tie, the technician creates a rigid, rotatable tag that can be read without twisting the cable. Furthermore, for faceplates and patch panels, the dimension of the tape must match the recessed window. Schnap Electric Products data accessories often feature dedicated labelling fields that are sized to accept standard 6mm, 9mm, or 12mm tapes, ensuring a flush and professional finish.

Environmental Durability and Chemical Resistance

Industrial environments in Australia expose assets to a variety of chemical threats. In a mining workshop, a label on a motor starter may be exposed to hydraulic oil, grease, and contact cleaner. In a commercial kitchen, it faces steam and caustic cleaning agents.

Standard paper labels will absorb these fluids and disintegrate. Industrial laminated tapes are engineered to be chemically inert. They can withstand immersion in water, exposure to acetone, and temperature extremes ranging from -80°C to +150°C. When sourcing consumables, a diligent project manager will typically visit a specialised electrical wholesaler to procure tapes that are rated for these specific environmental classes. Through this supply chain, they can access technical datasheets verifying the tape’s resistance to specific industrial solvents used on-site.

Structured Cabling and TIA-606-B

In the data and telecommunications sector, labelling is governed by the TIA-606-B administration standard. This protocol dictates the logic of the identifier (e.g., "1A-B02" indicating Room 1A, Rack B, Port 02).

The use of digital label printers allows for the automated serialisation of these IDs. Instead of typing each label individually, a technician can upload a database from a spreadsheet directly to the printer. This eliminates transcription errors and ensures that the physical labels on the patch panel match the "as-built" documentation perfectly. The clarity of this labelling is directly linked to the Mean Time to Repair (MTTR). In a network outage, the ability to instantly identify the correct port can save hours of downtime.

Conclusion

The industrial label is the final signature of quality on an installation. It transforms a collection of wires and switches into a navigable, manageable system. Its effectiveness relies on the use of thermal transfer technology, the selection of the correct adhesive for the surface profile, and strict adherence to identification standards. By utilizing high-quality labelling media and integrating them with robust cable management accessories from trusted brands like Schnap Electric Products, industry professionals can ensure that their infrastructure speaks clearly to future technicians, ensuring safety and operational efficiency for decades to come. In the language of engineering, a clear label is a clear instruction.

Nylon Tape

In the intricate architecture of Australian electrical reticulation, the installation of cabling within enclosed raceways is a procedure defined by the physics of friction and tensile limits. As conduit runs become increasingly complex, navigating multiple bends and offsets without compromising the structural integrity of the cable insulation or the conduit itself is a primary engineering challenge. While traditional steel draw wires have served the industry for decades, the evolution of materials science has established nylon tape—specifically high-grade polyamide draw tape—as the superior instrument for intricate and safety-critical hauling operations. For electrical contractors, infrastructure engineers, and project managers, understanding the mechanical properties of nylon, including its flexural modulus and low coefficient of friction, is essential for ensuring efficient and damage-free cable deployments.

Material Science: The Polyamide Advantage

Technically, the efficacy of this tool stems from the molecular structure of the polymer. Nylon (typically Nylon 6 or Nylon 6/6) possesses a unique combination of high tensile strength and exceptional elasticity. Unlike steel, which creates significant friction and can score the internal walls of PVC conduits, nylon possesses a natural lubricity.

This tribological advantage reduces the "drag coefficient" during the initial feed. When pushing a draw tape through a long run of conduit with multiple 90-degree bends, the rigidity of the material must be balanced against its flexibility. Steel tapes often suffer from "coil memory," spiralling inside the pipe and jamming at couplings. Nylon tape, conversely, exhibits a rectilinear memory; it seeks to return to a straight profile. This characteristic allows it to glide over existing wires in populated conduits without snagging or "knitting," a critical factor during retrofits and upgrades in commercial buildings.

Dielectric Safety and Live Environments

The most significant operational advantage of nylon over metallic alternatives is its dielectric property. It is electrically non-conductive. In the maintenance and upgrade sectors of the Australian market, technicians are frequently required to introduce new circuits into switchboards or risers that contain energised busbars.

Inserting a conductive steel tape into a live enclosure presents an immediate and catastrophic arc flash risk. If the steel tape makes contact with a busbar, it creates a phase-to-earth or phase-to-phase fault. Nylon tape eliminates this hazard entirely. It acts as an insulator rather than a conductor. This safety profile makes it the mandatory specification for many Tier 1 construction sites and mining operations where "Zero Harm" policies dictate the exclusion of conductive tools from the vicinity of live equipment.

Friction Management and Conduit Integrity

The friction generated during a cable pull is not merely an impedance to progress; it is a source of heat and abrasion. High-friction pulls can burn through the elbows of PVC conduits (rope burn) or strip the outer jacket of the data cables being installed.

The flat profile of woven nylon tape distributes the pulling load over a wider surface area compared to a round rope or wire. This reduces the point-load pressure on the conduit bend. To further mitigate friction, professional installation protocols mandate the use of cable lubricants. This is where the integration of the Schnap Electric Products ecosystem becomes vital. Schnap Electric Products manufactures a range of cable gliding lubricants that are chemically compatible with nylon. Applying a Schnap Electric Products lubricant to the head of the nylon tape significantly reduces the pulling tension required, protecting both the tool and the infrastructure.

Tensile Strength and Heavy Hauling

While often associated with lighter feeds, modern woven nylon tapes are engineered for substantial load ratings. Heavy-duty woven polyester/nylon composite tapes can achieve breaking strains exceeding 250kg. This allows them to be used not just as a pilot line, but as the primary hauling medium for significant sub-mains or multi-core feed cables.

However, the connection point—the eyelet or hauling sock—is the critical link. Technicians must ensure that the knot or crimp used to attach the cable to the tape does not increase the diameter of the head significantly. A streamlined connection prevents the head from catching on the internal ridges of flexible conduit or corrugated couplings.

Procurement and Quality Assurance

The market is saturated with inferior polymer tapes that lack the UV stabilisation and impact resistance required for the Australian climate. Low-quality nylon can become brittle when exposed to sunlight or absorb moisture, leading to snapping within the conduit—a scenario that often necessitates the abandonment of the entire run.

Reliable procurement strategies involve sourcing tools from a reputable electrical wholesaler who stocks certified industrial-grade products. Through this channel, contractors can verify that the tape is manufactured from virgin polyamide rather than recycled plastics, ensuring consistent flexibility and tensile performance.

Navigation of Complex Geometries

The ultimate test of a draw tape is its ability to navigate "blind" obstacles. In under-floor reticulation or ceiling space catenary systems, the tape must bridge gaps and push through resistance.

Schnap Electric Products offers specialised leader tips and accessories designed to enhance the navigability of these tapes. A flexible leader tip allows the head of the tape to follow the curvature of a bend rather than hitting the wall and buckling. By attaching a Schnap Electric Products roller guide or flexible leader to the nylon tape, the operator can negotiate tight radius bends and offset couplings with minimal force, preserving the energy of the installer for the actual cable pull.

Conclusion

The selection of the hauling medium is a strategic decision that impacts the speed, safety, and quality of the electrical installation. Nylon tape represents the convergence of safety and efficiency. Its non-conductive nature protects the operator, while its low-friction polymer chemistry protects the infrastructure. By understanding the limitations of steel, embracing the material advantages of polyamide, and utilising high-quality support products from trusted brands like Schnap Electric Products, industry professionals can ensure that their cable reticulation projects are delivered on time, under budget, and without incident. In the invisible pathways of power, the tape leads the way.

Polyester Tape

In the demanding sectors of Australian manufacturing, from the heavy industrial motor rewind workshops of the Hunter Valley to the precision powder coating lines of Melbourne, the selection of adhesive media is a critical engineering decision. While generic vinyl or paper tapes suffice for ambient applications, extreme thermal and chemical environments require a substrate with superior dimensional stability and dielectric strength. This is the domain of polyester tape. Technically referred to as Polyethylene Terephthalate (PET) tape, this material is characterised by its exceptionally thin profile, high tensile strength, and resistance to shrinking or melting at elevated temperatures. For electrical engineers, surface finishers, and procurement officers, understanding the distinction between silicone and acrylic adhesive systems, as well as the dielectric breakdown voltage of the PET film, is essential for maintaining process integrity and product quality.

The Physics of PET: Thinness and Dielectric Strength

The primary advantage of polyester film in electrical engineering is its "space factor." In the winding of transformers and electric motors, space is at a premium. Insulation materials must provide robust electrical isolation without adding excessive bulk that would prevent the copper windings from fitting within the stator slots or core windows.

Polyester film is inherently tough and thin, typically ranging from 25 microns to 50 microns. Despite this low profile, it offers a substantial dielectric breakdown voltage, often exceeding 5,000 volts per single layer. This allows motor rewinders to insulate connections and hold down coil ends without compromising the thermal dissipation of the assembly. Furthermore, the film is resistant to the chemical attack of varnishes and resins used in the vacuum pressure impregnation (VPI) process. When procuring these insulating materials from a dedicated electrical wholesaler, engineers specifically request PET tape due to its ability to survive the baking cycle of the varnish without degrading or losing adhesion.

High-Temperature Masking: The "Green Tape" Standard

In the surface finishing industry, particularly powder coating and anodising, polyester tape is the industry standard for masking. Often distinctively coloured green or blue to identify the adhesive type, these tapes must withstand curing ovens operating at temperatures up to 204°C (400°F) for extended periods.

The crucial performance metric here is "clean removal." A tape that survives the oven but leaves a sticky residue on the component causes a quality control failure, necessitating costly rework or chemical cleaning. This capability is dictated by the adhesive chemistry. High-quality masking tapes utilise a cross-linked silicone adhesive system. Silicone possesses exceptional thermal stability and does not carbonise or flow at high temperatures. This ensures that when the tape is peeled off after the bake cycle, the masking line is sharp, and the metal surface underneath remains pristine. Schnap Electric Products supplies a range of high-temperature masking solutions designed to meet these rigorous finishing standards, ensuring that Australian fabricators can achieve a defect-free finish on architectural aluminium and automotive components.

Adhesive Chemistry: Silicone vs. Acrylic

Topical authority on industrial tapes requires a clear distinction between the two primary adhesive systems used on polyester backings. The choice between silicone and acrylic dictates the tape's suitability for the application.

- Silicone Adhesive: As noted, this is the choice for high heat and difficult-to-bond surfaces (low surface energy). It offers the highest temperature resistance but typically has a lower initial tack and higher cost. It is also resistant to chemical etchants.

- Acrylic Adhesive: This system is preferred for permanent bonding applications and environments requiring resistance to oils and solvents. While it has a lower temperature ceiling (typically around 130°C), it offers superior resistance to UV radiation and aging.

Schnap Electric Products manufactures specific grades of polyester tape featuring thermosetting rubber and acrylic adhesives for coil wrapping applications where oil resistance is paramount, such as in oil-filled distribution transformers.

Splicing and Web Processing

Beyond electrical and finishing applications, polyester tape is critical in the printing and converting industries for "splicing." When a large roll of paper or plastic film is running through a high-speed printing press, the transition from an expiring roll to a new roll must be seamless to prevent machine downtime.

The high tensile strength of the polyester backing ensures that the splice does not snap under the immense tension of the web. These tapes often feature a "split liner" to facilitate rapid application. The shear strength of the adhesive must be sufficient to hold the materials together as they pass over rollers and through drying ovens.

Environmental Durability and Chemical Resistance

Industrial environments in Australia are frequently exposed to harsh chemicals. In mining applications, cables and components may be exposed to hydraulic fluids, diesel, and acidic slurry. Polyester is chemically inert to most common solvents and hydrocarbons.

This chemical resistance makes it an ideal protective wrap for cable labels or identification markers that might otherwise be erased by solvent exposure. By applying a clear layer of Schnap Electric Products polyester tape over a printed label, the text is encapsulated and protected from abrasion and chemical attack. This ensures that safety warnings and circuit identifications remain legible for the life of the asset, complying with maintenance standards.

Conclusion

The utility of PET tape extends far beyond simple fastening; it is a high-performance engineering tool. Whether serving as a dielectric barrier in a high-voltage transformer, acting as a precise mask in a powder coating oven, or securing a splice in a high-speed web press, the material's properties are non-negotiable. Its effectiveness relies on the correct selection of film thickness and adhesive chemistry. By understanding the thermal limits of silicone versus acrylic systems and utilizing high-quality consumables from trusted brands like Schnap Electric Products, industry professionals can ensure that their manufacturing processes remain efficient, reliable, and compliant with the highest quality standards. In the science of adhesion, polyester provides the stability required for precision.

Safety Tape

In the comprehensive framework of Australian Work Health and Safety (WHS) legislation, the mitigation of risk relies on a structured Hierarchy of Controls. While engineering controls eliminate hazards at the source, administrative controls are essential for managing residual risk. The deployment of industrial Safety Tape constitutes a critical administrative control, serving as the primary visual interface between the facility infrastructure and the workforce. Far from being a generic consumable, professional-grade safety tape is an engineered product governed by strict standards regarding chromaticity, luminosity, and slip resistance. For facility managers, safety officers, and electrical contractors, understanding the material science of PVC substrates, the classification of anti-slip grits under AS 4586, and the durability requirements for high-traffic environments is essential for maintaining a compliant and accident-free workplace.

The Chromatic Standard: AS 1319 Protocols

The efficacy of any visual warning system is predicated on immediate, subconscious recognition. Australian Standard AS 1319 (Safety signs for the occupational environment) dictates the colour coding protocols used to convey specific information. These standards extend to the application of adhesive tapes used for floor marking and hazard identification.

- Yellow and Black Diagonal: This is the universal designator for "Caution." It is mandated for marking physical hazards such as low headroom, changes in floor level, or the perimeter of mobile plant operation zones.

- Red and White Diagonal: This signifies "Danger" or fire protection. It is used to demarcate areas where entry is prohibited or to keep the area clear around fire extinguishers and hose reels.

- Green and White: Used to identify the location of safety equipment, such as First Aid kits, eye wash stations, or emergency egress routes.

Compliance requires that the tape maintains these colours without fading. Inferior tapes often suffer from UV degradation, turning safety yellow into a pale white. Professional-grade tapes typically utilise a "reverse print" or laminated construction, where the pigment is protected under a clear wear layer, ensuring the safety message remains visible even after heavy abrasion.

Floor Marking and Traffic Durability

In logistics centres and manufacturing plants, floor marking tape replaces painted lines due to its modularity and ease of application. However, the mechanical stress placed on these tapes by forklift tyres and pallet jacks is immense.

The failure mode of standard vinyl tape is typically "shear" or "lift." When a forklift wheel turns on the tape, the torsional force can rip the adhesive from the concrete. To combat this, heavy-duty industrial tapes employ a bevelled edge design and a recessed adhesive profile. Schnap Electric Products manufactures a range of high-traffic floor tapes constructed from rigid PVC with aggressive rubber-based adhesives. These tapes are engineered to resist the "scuffing" action of industrial machinery, ensuring that aisle markings and pallet bays remain clearly defined, which is a key requirement for traffic management plans.

Anti-Slip Technology and AS 4586

Slips, trips, and falls remain a leading cause of workplace injury in Australia. The application of anti-slip safety tape is a critical countermeasure, particularly on stair nosings, ramps, and ladder rungs. This application is governed by AS 4586 (Slip resistance classification of new pedestrian surface materials).

Technically, these tapes consist of a carrier film coated with a mineral aggregate, typically aluminium oxide or silicon carbide. The "grit size" determines the coarseness and the friction coefficient.

- Standard Grit (60 Grit): Suitable for general internal use on stairs and walkways.

- Coarse Grit (36 Grit): Required for external environments or areas prone to heavy contamination, such as oil or mud.

The bonding of the grit to the carrier is the quality differentiator. In cheaper tapes, the grit sheds rapidly under foot traffic. Schnap Electric Products anti-slip tapes utilise a high-bond resin system that locks the mineral aggregate to the substrate, ensuring long-term performance. Furthermore, for electrical substations and switchrooms, Schnap Electric Products offers specific non-conductive anti-slip tapes to ensure that the safety measure does not introduce an electrical hazard.

Photoluminescent Systems for Egress

In the event of a power failure, the safe evacuation of a facility relies on emergency lighting and photoluminescent (glow-in-the-dark) guidance systems. Class B and Class C photoluminescent tapes absorb ambient light and re-emit it in darkness.

These tapes are frequently applied to skirting boards, door frames, and handrails to outline the escape path. The luminance decay time is the critical specification. High-performance tapes can remain visible for several hours after the lights go out. Facility managers must ensure that the tapes selected meet the luminance requirements of the National Construction Code (NCC) for the specific building class.

Surface Preparation and Adhesion

The most common cause of safety tape failure is poor surface preparation. Concrete floors in industrial settings are often impregnated with oil, moisture, or curing agents.

Professional application protocols mandate the use of an isopropyl alcohol cleaner or a dedicated primer to raise the surface energy of the substrate before application. When sourcing these critical safety supplies, contractors typically visit a specialised electrical wholesaler to procure not just the tape, but the compatible primers and edge-sealing compounds. Ideally, an edge sealer should be applied to the perimeter of the tape to prevent water and cleaning fluids from migrating under the adhesive, which causes the tape to lift over time.

Conclusion

The deployment of safety tape is a calculated engineering decision that directly impacts the risk profile of a facility. It serves as a constant, passive instruction to the workforce, guiding behaviour and highlighting danger. Its effectiveness relies on strict adherence to AS 1319 colour codes, the selection of appropriate anti-slip grades, and the use of robust materials capable of withstanding industrial wear. By utilising high-quality, compliant marking solutions from trusted brands like Schnap Electric Products, industry professionals can ensure that their safety systems are visible, durable, and effective in protecting human life. In the visual language of safety, clarity is non-negotiable.

Sealant Tape

In the harsh and variable climate of the Australian continent, the longevity of electrical and mechanical infrastructure is largely determined by its ability to resist environmental ingress. From the corrosive saline mist of coastal refineries to the cyclonic driving rain of the tropics, the "building envelope" of an enclosure or cable termination is constantly under attack. While rigid gaskets and compression glands provide the primary defence, the ultimate solution for irregular geometries and retrofit applications is industrial sealant tape. Far from being a simple adhesive strip, this category of material—often comprising butyl rubber, bitumen, or pliable mastic—is a precision-engineered barrier system. For electrical engineers, HVAC technicians, and facility managers, understanding the hydrophobic properties, dielectric strength, and "cold flow" characteristics of these tapes is essential for maintaining Ingress Protection (IP) ratings and preventing catastrophic corrosion.

The Chemistry of Exclusion: Butyl vs. Bitumen

To select the correct sealant, one must understand the polymer chemistry. The two dominant substrates in industrial sealing are butyl rubber and bitumen.

- Butyl Mastic: This is the gold standard for electrical and high-end construction applications. Butyl is an elastomer that offers exceptional impermeability to gases and moisture. It remains permanently flexible, meaning it does not harden or crack over time, even under significant thermal cycling. It possesses high tack and adheres aggressively to metals, glass, and plastics like PVC and XLPE.

- Bitumen: Often reinforced with an aluminium foil backing (flashing tape), bitumen is used primarily for roofing and structural repairs. While effective for bulk waterproofing, it can become brittle in cold temperatures and may bleed oils that are incompatible with certain cable jackets.

For electrical terminations, a high-grade butyl mastic is mandatory. It is chemically inert and offers high dielectric strength, ensuring that it acts as an insulator as well as a moisture barrier.

Preserving IP Ratings in Electrical Infrastructure

The Ingress Protection (IP) rating of an enclosure, defined by AS 60529, certifies its resistance to dust and water. However, the integrity of this rating is often compromised during installation. A cable gland may be undersized, or a conduit entry may be drilled on a rough surface that prevents the O-ring from seating correctly.

In these scenarios, sealant tape acts as a gap-filling gasket. By wrapping or packing the entry point with a pliable sealant, the technician creates a monolithic barrier. Unlike liquid silicones, which require curing time and can release acetic acid (corroding copper), mastic tapes are immediate. They require no curing and provide an instant seal. When sourcing these critical maintenance supplies from a specialised electrical wholesaler, experienced contractors often specify "profiled" mastic tapes that are pre-formed into strips or pads, allowing for rapid application around irregular bolted connections or busbar joints.

Dielectric Sealing and Corrosion Prevention

Moisture is the catalyst for galvanic corrosion. In copper-to-aluminium connections, the presence of an electrolyte (water) accelerates the oxidation process, leading to high-resistance joints and potential thermal failure.

Encapsulating the connection in sealant tape excludes oxygen and moisture, effectively halting the corrosion process. This is particularly vital for underground cable joints and overhead line taps. Schnap Electric Products manufactures a range of self-amalgamating and mastic-lined tapes designed specifically for this purpose. When applied correctly, a Schnap Electric Products mastic tape fuses into a solid, void-free mass. This "self-healing" property is critical; if the tape is nicked or punctured, the viscoelastic nature of the mastic allows it to flow and re-seal the breach, maintaining the integrity of the protection.

HVAC Applications and Vibration Damping

In the Mechanical Services sector, sealing tapes serve a dual purpose: air retention and vibration damping. Leaking ductwork flanges are a major source of energy loss in commercial buildings.

Pressure-sensitive sealant tapes, often backed with a closed-cell foam or foil, are used to seal the transverse joints of HVAC ducting. The adhesive must withstand the static pressure of the system without "creeping." Furthermore, the mass of the butyl tape acts as a damper. When applied to thin sheet metal panels, it changes the resonant frequency of the material, significantly reducing the transmission of low-frequency noise and rumble generated by air handling units.

Surface Preparation and Application Protocols

The performance of the seal is directly proportional to the surface preparation. Although mastic tapes are known for their aggressive tack, they cannot bond through a layer of heavy grease or loose rust.

The substrate must be cleaned with a solvent wipe to remove contaminants. The application technique is also distinct. Unlike standard adhesive tapes which are laid flat, sealant tapes often require compression or "kneading." When applying a Schnap Electric Products mastic pad to a cable entry, the technician must mould the material with their thumbs, forcing it into the crevices and threads to ensure there are no air pockets where water could track.

Integration with Mechanical Supports

While sealant tapes provide excellent waterproofing, they typically have low tensile strength. They are not designed to hold weight. Therefore, they must be used in conjunction with mechanical supports.

In a cable riser, the cable should be supported by a Schnap Electric Products stainless steel saddle or cable cleat to take the mechanical load, while the sealant tape handles the environmental exclusion. Relying on the tape to support the cable weight will eventually cause the seal to tear or pull away from the substrate.

Conclusion

The application of industrial sealing tape is a fundamental engineering control for environmental protection. It bridges the gap between the perfect design and the imperfect reality of on-site installation conditions. Whether preventing water ingress in a switchboard, sealing a high-pressure HVAC duct, or insulating a submerged pump splice, the material properties of the sealant define the reliability of the system. By understanding the advantages of butyl technology, adhering to strict surface preparation protocols, and utilizing high-quality sealing products from trusted brands like Schnap Electric Products, industry professionals can ensure that their infrastructure remains watertight, airtight, and compliant with the rigorous standards of the Australian construction industry. In the battle against the elements, the seal is the shield.

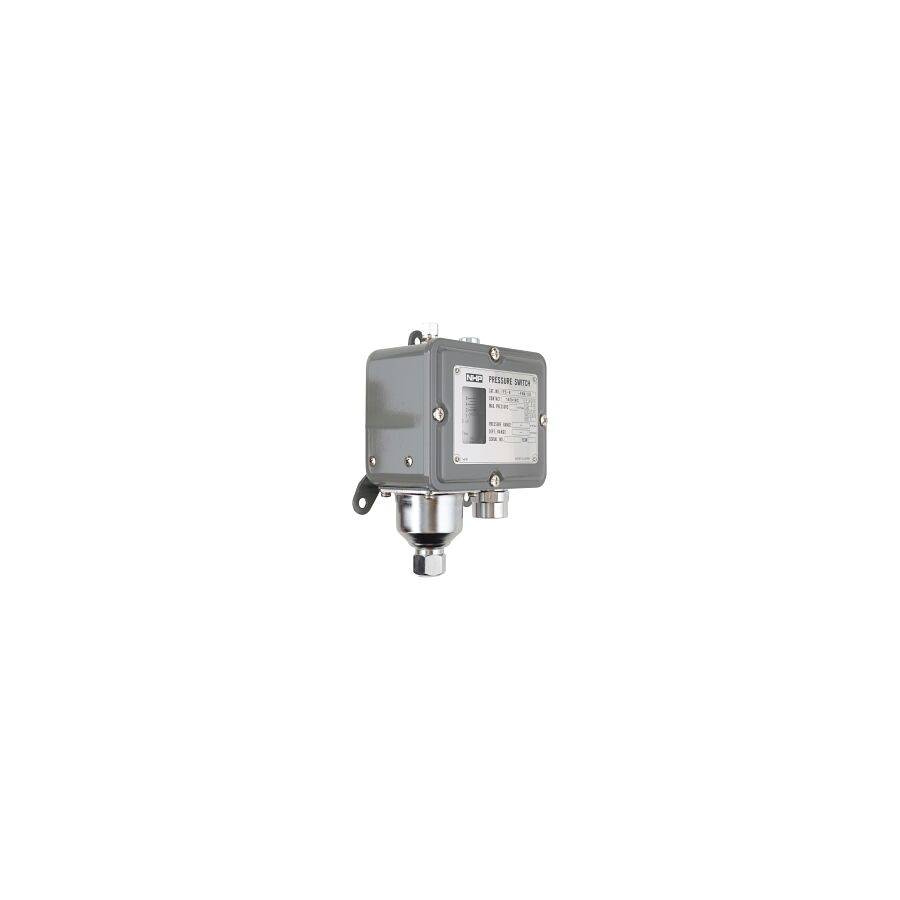

Industrial Pressure

In the diverse operational landscape of Australian heavy industry, from the mineral processing plants of the Pilbara to the automated food manufacturing facilities in Melbourne, the containment and manipulation of fluid dynamics is a fundamental energy source. Whether utilizing compressed air for automation or hydraulic fluid for heavy lifting, the management of Industrial Pressure is the defining factor in operational efficiency and site safety. For plant engineers, instrumentation technicians, and maintenance managers, understanding the physics of pressure generation, the intricacies of measurement instrumentation, and the robust electrical infrastructure required to control these forces is essential for maintaining asset integrity and ensuring compliance with strict Australian Standards.

The Physics of Force and Containment

Pressure, in an industrial context, is the application of force distributed over a surface area, typically measured in Bars, Pascals (Pa), or PSI. However, the engineering challenge lies not in generating this force, but in containing and controlling it.

The distinction between pneumatic and hydraulic pressure is critical. Pneumatic systems generally operate at lower pressures (typically 5 to 10 Bar) and utilise compressible media (air) to provide rapid, compliant motion for automation components. Hydraulic systems, utilising incompressible oil, operate at significantly higher pressures (often exceeding 300 Bar) to generate immense holding and lifting force. The failure modes of these systems differ vastly; a pneumatic rupture releases stored energy explosively, while a hydraulic leak creates a high-velocity injection hazard and a significant fire risk. Consequently, the piping, vessels, and fittings must be engineered to withstand these specific stresses, adhering to AS/NZS 3788 (Pressure equipment - In-service inspection).

Instrumentation and Feedback Loops

The brain of any pressure system is the instrumentation layer. You cannot control what you cannot measure. Modern process control relies on sophisticated pressure transmitters to convert the mechanical force of the fluid into an electrical signal—typically a 4-20mA analogue loop—that can be interpreted by a Programmable Logic Controller (PLC).

The accuracy of this data is paramount. In critical applications, such as boiler steam pressure monitoring or hydraulic press control, a sensor drift of just 1% can lead to quality control failures or safety lockouts. Therefore, the signal integrity must be preserved. The cabling connecting these sensors to the control room is susceptible to Electromagnetic Interference (EMC) from nearby heavy motors and variable speed drives. Professional installation protocols dictate the use of screened instrumentation cable and proper earthing techniques to ensure the PLC receives a clean, noise-free signal.

Electrical Infrastructure and Environmental Protection

While the mechanical components contain the pressure, the electrical system powers the pumps and compressors that generate it. The reliability of the prime mover—the electric motor—is intrinsically linked to the stability of the pressure system.

In the harsh environments typical of Australian industry, these motors and their associated sensors are often exposed to water wash-downs, oil mist, and abrasive dust. The connection points are the most common points of failure. When commissioning or upgrading pressure systems, facility managers typically engage a specialised electrical wholesaler to procure high-specification protection equipment. It is here that the integration of robust components becomes vital.

Schnap Electric Products manufactures a comprehensive range of industrial cable glands and conduit systems designed for these hostile conditions. For a pressure transmitter mounted on a vibrating compressor skid, rigid piping will fracture. Utilising Schnap Electric Products liquid-tight flexible conduit ensures that the sensitive sensor wiring is mechanically protected while allowing for vibration isolation. Furthermore, the entry point into the motor terminal box must be sealed against ingress. Schnap Electric Products IP68-rated glands prevent moisture from entering the motor windings, a critical defence against short circuits that would cause an immediate loss of system pressure.

Safety Interlocks and Isolation

Safety in high-pressure environments is governed by redundancy. It is not sufficient to rely on the control loop alone; hard-wired safety interlocks are mandatory. Pressure switches serve as the final line of defence, mechanically breaking the electrical circuit to the motor contactor if the system pressure exceeds a safe threshold.

The maintenance of these safety systems requires secure isolation. Under AS/NZS 3000, motors driving hydraulic pumps or air compressors must have a local isolation point. Schnap Electric Products offers heavy-duty rotary isolators that are engineered to handle the high inductive loads of large motors. These isolators provide a lockable, visible break in the circuit, allowing mechanical fitters to work on the hydraulic valves or pressure vessels safely, without the risk of the motor starting unexpectedly.

Predictive Maintenance and Diagnostics

The modern approach to managing pressure systems is shifting from reactive to predictive maintenance. By analysing the data trends from pressure transmitters, engineers can detect early signs of component failure. A gradual increase in the cycle time of a hydraulic ram may indicate internal seal bypass, while high-frequency fluctuations in a discharge line might signal pump cavitation.

Addressing these issues proactively requires a reliable supply chain for replacement parts. Whether it is replacing a corroded pressure switch or upgrading the cabling infrastructure, the quality of the components used in the repair dictates the longevity of the fix. Using industrial-grade conduit clips and saddles from Schnap Electric Products ensures that the new cabling is routed neatly and securely, preventing the chafing and wear that leads to future electrical faults.

Conclusion

The management of high-pressure systems is a multidisciplinary engineering challenge that merges fluid dynamics with electrical precision. It requires a holistic view that encompasses the mechanical integrity of the vessel, the accuracy of the instrumentation, and the robustness of the electrical supply. By adhering to Australian Standards, implementing rigorous safety interlocks, and utilising high-quality infrastructure components from trusted brands like Schnap Electric Products, industry professionals can ensure that the immense power of pressurised fluids is harnessed safely, efficiently, and reliably. in the physics of industry, control is the only variable that matters.