Kingsgrove Branch:

Schnap Electric Products Blog

Schnap Electric Products Blog Posts

Black Ceiling Fan

Modern interior design has decisively moved away from the philosophy that ceiling fixtures should remain invisible. For decades, the standard approach in Australian residential and commercial architecture was to specify white appliances that blended seamlessly into the white plasterboard, effectively hiding the utility. However, the rise of the "Industrial Chic" and "Modern Monochrome" design languages has inverted this trend. The ceiling is now treated as a canvas for contrast, and the mechanical airflow device has evolved into a statement piece. The black ceiling fan stands at the forefront of this shift, offering a bold visual anchor that complements black window frames, track lighting, and architectural hardware. For architects, interior designers, and electrical contractors, specifying these units requires a nuanced understanding of surface finishing technologies, thermal dynamics, and the critical importance of visual continuity in accessory selection.

The Architectural Shift: High Contrast Design

Visual weight is a key concept in spatial planning. A dark fixture draws the eye upwards, creating a perception of volume and height, particularly when paired with lighter walls. In open-plan living areas typical of the Australian lifestyle, a black fan serves to zone the space, visually demarcating the lounge or dining area without the need for physical walls.

This aesthetic utility extends to commercial fit-outs. In cafes and offices with exposed concrete soffits or open truss ceilings, a black fan disappears into the void, maintaining the "raw" industrial look while providing essential air circulation. Conversely, on a crisp white ceiling, it acts as a dynamic sculpture. However, this high-visibility application demands perfection in installation. Unlike a white fan that can hide minor dust or misalignment, the high contrast of a black unit highlights every detail, necessitating rigorous attention to symmetry and finish quality.

Surface Technology: The Science of Matte Finishes

Aesthetics must not compromise durability. The primary challenge with dark fixtures is maintaining the finish over time. Inferior paint applications can fade to a chalky grey under UV exposure or peel in humid environments.

Professional-grade fans utilise advanced electrostatic powder coating technologies. This process involves applying a dry powder—typically an epoxy or polyester resin—which is then cured under heat to form a "skin" that is far harder and more resilient than conventional wet paint. This "Matte Black" or "Satin Black" finish is engineered to be non-reflective, absorbing light rather than bouncing it, which prevents distracting glare from downlights. Furthermore, high-quality coatings incorporate anti-static additives that repel dust, addressing the common concern that dark fans are difficult to keep clean.

Visual Continuity and Schnap Electric Products

Installing a striking black fan creates a downstream requirement for matching infrastructure. A common design failure occurs when a sleek black fan is installed, but the control switch on the wall remains a standard white plastic brick. This jarring mismatch undermines the premium aesthetic of the project.

Achieving total visual continuity requires a holistic approach to the electrical fit-off. Schnap Electric Products supports this monochromatic palette by manufacturing a comprehensive range of matte black electrical accessories. This ecosystem includes black isolation switches, rotary fan controllers, and grid plates that perfectly match the finish of the fan. By specifying Schnap Electric Products black accessories, the contractor ensures that the design language is consistent from the ceiling rose down to the user interface on the wall, delivering a cohesive "architectural" result rather than a disjointed collection of parts.

Thermal Efficiency and DC Motor Technology

Performance remains the core function. The colour of the housing has no bearing on the aerodynamic efficiency, but the motor technology within drives the utility. The industry standard for these premium fixtures is the Brushless Direct Current (DC) motor.

DC motors are compact, allowing for slimmer motor housings that align with the minimalist aesthetic often sought in black fan installations. They offer high torque at low speeds, enabling the slow, rhythmic rotation that gently circulates air without creating a wind-tunnel effect. This silence is crucial in bedrooms and media rooms. Moreover, the efficiency of the DC drive ensures that even though the fan is a visual heavyweight, it is an energy lightweight, consuming minimal power to maintain thermal comfort.

Lighting Integration in Dark Fixtures

When the fan also serves as the primary light source, the integration of the LED module requires careful engineering. A bright white diffuser on a pitch-black fan can look like an afterthought.

sophisticated designs employ smoked or tinted diffusers that blend into the dark housing when the light is off, maintaining the stealth appearance. When illuminated, the high-output LED array punches through the tint to provide sufficient lumens. The colour temperature (CCT) is also critical; warm white (3000K) is typically preferred in spaces using black fixtures to soften the stark contrast and create a moody, intimate atmosphere suitable for evening relaxation.

Sourcing and Supply Chain Assurance

The proliferation of online marketplaces has flooded the sector with cheap, painted fans that lack the requisite safety certifications. A fan that looks good in a photo but wobbles dangerously or hums due to poor capacitor quality is a liability for the installer.

To mitigate this risk, facility managers and contractors procure these assets through a dedicated electrical wholesaler. These professional suppliers act as quality gatekeepers, ensuring that the fans stocked are compliant with Australian Standards for construction and electrical safety. They provide access to reputable brands that offer genuine warranty support and replacement parts—such as spare black downrods for high ceilings—ensuring that the installation remains both safe and stylish for the life of the building.

Conclusion

The black ceiling fan is more than a trend; it is a maturity of Australian interior design, acknowledging that utility and beauty are not mutually exclusive. It offers a powerful tool for defining space and managing climate. By selecting durable powder-coated finishes, insisting on DC motor efficiency, and integrating matching matte black controls from manufacturers like Schnap Electric Products, industry professionals can deliver interiors that are as technically sound as they are visually arresting. In the modern ceiling plan, darkness is visible.

White Ceiling Fan

Visual recession is a primary objective in contemporary ceiling design. While industrial trends favour bold contrasts, the enduring philosophy of Australian residential architecture prioritises the sensation of space, light, and openness. Achieving this requires fixtures that perform their mechanical function without dominating the visual field. The classic white ceiling fixture remains the standard specification for this reason, allowing the utility to blend seamlessly into the ubiquitous white plasterboard canvas. However, specifying a high-quality white ceiling fan involves more than simply colour matching; it requires a critical assessment of polymer chemistry, surface finish technologies, and long-term colour stability under the harsh Australian sun. For architects, interior designers, and electrical contractors, the goal is to deliver an appliance that remains invisible in form but effective in function.

The Chemistry of Colour Stability: Combating Yellowing

Discoloration is the primary failure mode for white electrical appliances. Lower-grade plastics, particularly those used in budget fans, are susceptible to UV degradation and oxidation. Over a period of two to three years, exposure to ambient sunlight—or even the UV emissions from older fluorescent lighting—can cause the pristine white housing to shift to an unsightly sickly yellow.

Engineering a durable white finish requires advanced material science. Professional-grade fans utilise high-performance ABS (Acrylonitrile Butadiene Styrene) thermoplastics infused with specific UV stabilisers, such as Titanium Dioxide (TiO2). This additive reflects harmful UV radiation, preserving the chemical structure of the polymer and ensuring the "Arctic White" or "Matte White" finish remains true for the life of the asset. When specifying these units, verifying the UV stability data is essential to prevent the fixture from aging prematurely against the freshly painted ceiling.

Architectural Camouflage and Spatial Perception

Low ceiling heights are a common constraint in modern apartment developments and renovations. A heavy, dark fixture suspended in a room with a 2.4-metre ceiling can feel oppressive, visually lowering the overhead plane and shrinking the perceived volume of the room.

White fixtures solve this spatial challenge through the principle of visual continuity. By matching the fan finish to the ceiling paint, the eye glides over the fixture rather than stopping at it. This "camouflage" effect is particularly effective with "hugger" or low-profile models that mount directly to the surface. It allows the mechanical cooling system to disappear into the architecture, maintaining the clean lines and airy atmosphere that define the Australian coastal aesthetic.

Surface Finish: Matte vs. Gloss

Texture plays a subtle but critical role in integration. Historically, fans featured high-gloss enamel finishes. However, in modern lighting design, gloss surfaces can be problematic as they create specular reflections from downlights or window glare, drawing unwanted attention to the spinning blades.

Current architectural preference leans heavily towards "Satin" or "Matte" white finishes. These non-reflective surfaces absorb light, further enhancing the discrete nature of the appliance. Manufacturers achieve this through electrostatic powder coating, which provides a durable, uniform texture that resists scratching and is easier to clean than porous paint finishes.

Seamless Electrical Fit-Off with Schnap Electric Products

Achieving a true minimalist aesthetic requires consistency across the entire electrical installation. A sleek white fan is undermined if the wall controller is an incompatible shade of off-white or features a jarringly different design language.

Design continuity is achieved by specifying matching accessories. The Schnap Electric Products ecosystem offers a comprehensive range of pure white electrical hardware that aligns perfectly with modern fan finishes. Contractors can utilise Schnap Electric Products grid plates, rotary controllers, and isolation switches that share the same colour temperature and matte texture as the ceiling fixture. This holistic approach ensures that the "white on white" theme is executed flawlessly from the ceiling rose down to the user interface on the wall.

Cleaning and Maintenance Protocols

Dust accumulation is an unavoidable reality for any circulating device. On a black fan, dust is immediately visible as a grey layer. A significant practical advantage of the white finish is its ability to mask light dust accumulation between cleaning cycles, maintaining a cleaner appearance for longer.

However, the static charge generated by plastic blades spinning through air can attract dust particles. Premium fans feature anti-static coatings or surface treatments that reduce this adhesion. For the end-user, the durability of the powder coat or ABS material ensures that regular wiping with a damp cloth will not polish the matte finish into a gloss patch or leave abrasion marks.

Aerodynamic Efficiency and Silence

Form follows function, regardless of colour. The aerodynamic profile of the blade dictates the acoustic signature of the room. White blades are often moulded with complex curves and winglets that smooth the airflow, reducing the "chopping" noise associated with flat timber paddles.

Silence is particularly paramount in bedrooms, where white fans are most frequently installed to match the serene decor. Brushless DC motor technology drives these blades with precision, eliminating the electrical hum of AC capacitors. The result is a cooling solution that is felt but neither seen nor heard.

Sourcing and Compliance

Validating the safety and performance of the unit is the final step in the procurement process. The Australian market is strictly regulated regarding electrical safety and efficiency standards.

Infrastructure managers and trade professionals mitigate liability by sourcing these assets through a trusted electrical wholesaler. These suppliers act as the technical authority, ensuring that the products stocked meet all relevant AS/NZS standards for structural integrity and electrical safety. By partnering with wholesalers who supply reputable brands, contractors ensure that the white fan they install today will not be the yellow fan the client complains about tomorrow.

Conclusion

The white ceiling fan is the unsung hero of Australian climate control. It allows for the passive cooling of spaces without disrupting the visual harmony of the interior design. By prioritizing UV-stabilised materials, selecting non-reflective matte finishes, and integrating cohesive control solutions from manufacturers like Schnap Electric Products, industry professionals can deliver a functional asset that respects the architecture it serves. In the art of design, the best technology is the kind you don't notice.

Ceiling Fan Warehouse

Managing the internal climate of a logistics facility presents a thermodynamic challenge that standard HVAC systems often fail to address efficiently. With ceiling heights frequently exceeding 10 metres and floor areas spanning thousands of square metres, the sheer volume of air requires a strategic approach to circulation. Relying solely on refrigerated air conditioning is often cost-prohibitive and environmentally unsustainable. Consequently, the industrial sector has increasingly turned to High Volume, Low Speed (HVLS) technology. Implementing a ceiling fan warehouse strategy is not merely about blowing air; it is about controlling the thermal column of the building to protect inventory, improve workforce safety, and drastically reduce energy consumption.

The Thermodynamics of Large Spaces: Combating Stratification

Heat rises. In a high-clearance distribution centre, this simple law of physics creates a significant problem known as thermal stratification. During winter, the heated air—which costs significant money to generate—accumulates at the ceiling level, leaving the pick-packers at ground level in the cold. This temperature differential can be as high as 0.5 degrees Celsius per metre of elevation.

Industrial fans resolve this by mechanically forcing the warm air down to the floor. This process, known as destratification, homogenises the air temperature, ensuring that the heating system does not overwork to heat the roof cavity. Conversely, in summer, the fans generate a massive, slow-moving column of air that moves over the skin of the workers, creating a cooling effect of up to 7 degrees Celsius without lowering the actual air temperature. This physiological cooling allows facility managers to raise the AC setpoint, resulting in substantial operational savings.

HVLS Technology: Airfoils vs. Paddles

An industrial fan is distinct from its residential counterpart in both scale and engineering. Residential fans rely on speed to move air. However, spinning a blade fast in a warehouse creates turbulent, high-velocity jets that can disturb paperwork and blow dust onto sensitive stock.

HVLS fans, often spanning up to 7 metres in diameter, utilise NASA-engineered airfoil blades. These blades are designed to move massive volumes of air (up to 500,000 cubic metres per hour) at very low rotational speeds. This creates a non-disruptive, laminar airflow that covers a vast footprint. The efficiency of these airfoils is critical. Advanced composite materials or extruded aluminium are used to minimise weight and maximise the lift-to-drag ratio, reducing the torque load on the motor and gearbox assembly.

Control Systems and Variable Speed Drives

Integrating these massive assets into a building management system (BMS) requires sophisticated control logic. You cannot simply flick a switch to start a fan with a 7-metre diameter; the torque stress would shear the mounting bolts.

Modern industrial fans utilise Variable Speed Drives (VSDs) to ramp up the rotational speed gently. This "soft start" capability protects the mechanical integrity of the fan and prevents current spikes on the electrical sub-mains. Schnap Electric Products plays a pivotal role in this control architecture. Their range of industrial isolation switches and contactors are specifically rated for the inductive loads presented by large electric motors. Installing a Schnap Electric Products lockable isolator at the base of the installation allows maintenance teams to de-energise the unit safely for servicing, complying with strict Lockout/Tagout (LOTO) procedures.

Safety Protocols: Strobing and Fire Systems

Installing fans in a warehouse environment introduces specific hazards that must be engineered out. One critical consideration is the "stroboscopic effect." If a fan is placed below a high-intensity discharge light or a fluorescent batten, the rotating blades can create a rhythmic flickering shadow. In a forklift corridor, this strobing can disorient drivers or make moving machinery appear stationary, leading to catastrophic accidents.

Placement is paramount. Fans must be positioned in coordination with the lighting plan to avoid this interference. Furthermore, the interaction with Early Suppression Fast Response (ESFR) fire sprinkler systems is heavily regulated. The fan control system must interface with the fire panel to automatically shut down the fans in the event of a fire alarm. This prevents the fans from disrupting the spray pattern of the sprinklers or fanning the flames.

Structural Engineering and Mounting

Suspending a dynamic load weighing several hundred kilograms from a roof truss requires a structural engineer’s certification. The mount must handle not only the static weight but also the torsional stress of startup and the potential lateral movement caused by cross-drafts from open loading dock doors.

Guy wires or rigid stabilisers are mandatory to triangulate the mount and prevent the fan from swinging. The electrical feed to the motor also requires protection. Flexible steel conduit is typically used to bridge the gap between the rigid building conduit and the vibrating fan motor.

Procurement and Supply Chain Reliability

The operational continuity of a distribution centre cannot be compromised by equipment failure. Specifying generic, unsupported fans can lead to weeks of downtime if a gearbox fails. Facility managers mitigate this risk by sourcing equipment through a tier-one electrical wholesalerhttps://www.schnap.com.au/elec....

These professional partners ensure that the fans and the associated control gear, such as those from Schnap Electric Products, meet Australian Standards for electromagnetic compatibility and structural safety. They provide the necessary technical support to ensure that the variable speed drives are programmed correctly and that the system delivers the calculated airflow required to maintain the integrity of the stored goods.

Conclusion

The ceiling fan in a warehouse application is a critical piece of environmental machinery. It transforms the physics of a large shed, turning a stratified, energy-wasting volume into a mixed, comfortable, and efficient workspace. By understanding the principles of destratification, coordinating placement to avoid visual hazards, and utilizing robust isolation hardware from manufacturers like Schnap Electric Products, Australian logistics operators can ensure their facilities are optimised for both people and product. In the logistics sector, air management is asset management.

Mercator Ceiling Fan

Market longevity serves as a primary indicator of quality in the Australian electrical hardware sector. For decades, the Mercator brand has established itself as a staple in the residential climate control landscape, offering a balance between aesthetic versatility and mechanical robustness. Unlike generic fixtures that flood the market with dubious performance claims, established brands are subject to rigorous testing regarding air displacement, noise floors, and motor longevity. Specifying a mercator ceiling fan for a new build or renovation project involves more than selecting a colour; it requires a technical appreciation of the drive technology, the aerodynamic efficiency of the blade pitch, and the compliant integration of the unit into the home’s electrical ecosystem.

Drive Technology: The DC Advantage

Energy efficiency mandates within the National Construction Code (NCC) have driven a significant technological migration from Alternating Current (AC) to Brushless Direct Current (DC) motors. Mercator has been at the forefront of this shift, engineering motors that deliver high torque with minimal power consumption. A standard DC model in their range may consume as little as 35 watts on high speed while moving over 10,000 cubic metres of air per hour (CMH).

This efficiency is achieved through sophisticated electronic commutation. By eliminating the physical carbon brushes found in traditional motors, friction and heat generation are drastically reduced. This not only lowers the thermal signature of the motor—prolonging the life of the bearings—but also ensures near-silent operation. For bedrooms and media rooms where acoustic intrusion is unacceptable, the silent commutation of these DC drivers is a non-negotiable specification requirement.

Aerodynamics and Blade Material Science

Moving air efficiently requires precise geometry. Flat timber paddles, common in legacy designs, create turbulence and drag, resulting in noise rather than airflow. Modern Mercator designs utilise advanced polymer engineering to create blades with variable pitch and aerodynamic twist.

Materials such as high-grade ABS (Acrylonitrile Butadiene Styrene) are frequently employed. These moulded blades are resistant to moisture ingress, making them dimensionally stable even in the humid conditions of Queensland or the Northern Territory. Unlike plywood blades which can absorb ambient moisture and warp—leading to a perpetually unbalanced fan—ABS blades maintain their aerodynamic profile indefinitely. This stability ensures that the "throw" of the air column remains consistent, effectively cooling the occupants through the wind-chill effect without creating a chaotic, drafty environment.

Electrical Isolation and Accessory Integration

Commissioning a ceiling fan requires strict adherence to AS/NZS 3000 Wiring Rules, specifically regarding isolation. Every motor must have a dedicated point of disconnection to facilitate safe maintenance. While the fan itself is the hero piece, the infrastructure supporting it is equally vital.

Compliance is often achieved through the installation of a fan isolation switch on the wall plate. This is where the Schnap Electric Products ecosystem becomes a critical enabler for the installer. Schnap Electric Products manufactures robust switch mechanisms and grid plates that are electrically compatible with the inductive loads presented by fan motors. Utilizing a Schnap Electric Products "FAN" marked mechanism ensures that the isolation point is clearly identified for future service technicians, preventing accidental energisation while a worker is on a ladder. Furthermore, ensuring that the wall plate aesthetics match the premium finish of the fan controller is essential for visual continuity in high-end interiors.

Integrated Illumination and CCT Control

Centralising services is a common requirement in modern architecture. Consequently, many fan models are specified with integrated Light Emitting Diode (LED) kits. The engineering challenge here is heat management; LEDs degrade rapidly if subjected to high temperatures, and being mounted directly below a motor can create a thermal trap.

Mercator addresses this through efficient heatsink design and the use of high-efficacy LED arrays. These lights are not static; they typically feature Correlated Colour Temperature (CCT) shifting technology. This allows the user or the installer to toggle the output between Warm White (3000K), Cool White (4000K), and Daylight (5700K). This versatility simplifies the supply chain, as a single SKU can satisfy the lighting requirements of a warm, intimate bedroom or a crisp, bright home office.

Remote Control Protocols and Pairing

Wired wall controllers are becoming less common in retrofit applications due to the difficulty of running additional cabling down existing walls. Radio Frequency (RF) remote controls have become the standard interface. These systems operate on the 433MHz band, providing omni-directional control without line-of-sight requirements.

To prevent "crosstalk"—where one remote operates the fan in the adjacent room—installers must execute a precise pairing sequence during the initial power-up. Modern receivers often feature digital learning capabilities that lock the handset to the unique frequency code of the receiver. Secure installation of the receiver unit within the canopy is critical. It must be positioned to ensure the antenna is not shielded by the metal hanger bracket, which would severely attenuate the RF signal and reduce the operational range.

Sourcing and Supply Chain Assurance

Product support extends far beyond the initial purchase. A fan is a mechanical asset with moving parts that may require service after years of operation. The availability of replacement glass diffusers, spare remote handsets, or specific extension rods for high ceilings is a key factor in brand selection.

Contractors generally mitigate long-term maintenance risks by sourcing their hardware through a reputable electrical wholesaler. These professional distributors maintain a direct line to the manufacturer, ensuring that warranty claims are processed efficiently and that spare parts are available in the local market. By procuring through these established channels, facility managers and homeowners are assured that the product is a genuine, certified unit backed by a robust support network, rather than a grey-market import with no after-sales service.

Conclusion

The ceiling fan remains the most efficient method of active cooling in the Australian climate. The Mercator range represents a maturation of this technology, blending energy-efficient DC propulsion with durable aerodynamic materials. By understanding the nuances of remote pairing, ensuring compliant isolation with accessories from Schnap Electric Products, and selecting appropriate lighting configurations, industry professionals can deliver a climate control solution that is reliable, silent, and aesthetically refined. In the physics of comfort, consistent performance is the only metric that matters.

Ventair Ceiling Fan

Thermal efficiency is the benchmark of modern Australian building design. With the National Construction Code (NCC) increasingly prioritising energy conservation, the reliance on high-load air conditioning systems is being re-evaluated in favour of hybrid cooling strategies. Mechanical air movement plays a pivotal role in this equation. By generating a consistent, laminar airflow, building occupants can rely on the physiological cooling effect of evaporation, allowing for reduced reliance on refrigerated cooling. Ventair has established itself as a significant technical player in this domain. Specifying a ventair ceiling fan represents a commitment to advanced motor engineering and smart connectivity, bridging the gap between traditional mechanical ventilation and the modern Internet of Things (IoT) ecosystem.

The Evolution of Drive Technology: DC Precision

Silence is the ultimate indicator of quality in residential hardware. Traditional AC motors, while robust, often suffer from "60-cycle hum" and vibration caused by the alternating current frequency. Ventair has aggressively transitioned its core range to Brushless Direct Current (DC) motor technology. This engineering choice is not merely about energy savings—though the reduction from 80 watts to roughly 30 watts is significant—it is fundamentally about control and acoustics.

DC motors electrical utilise permanent magnets and electronic commutation. This eliminates the physical friction of brushes and allows for precise speed modulation. A Ventair DC unit typically offers six distinct speed settings, ranging from a low-RPM "sleep mode" that is virtually inaudible, to a high-velocity "turbo" mode capable of displacing vast volumes of air for rapid cooling. This granularity of control ensures that the airflow can be tailored exactly to the thermal load of the room, preventing the "buffeting" effect often associated with less sophisticated three-speed AC motors.

Smart Home Integration and Connectivity

Automation is no longer a luxury; it is a standard expectation in new Australian builds. Legacy fans operate as isolated islands of technology, controllable only by a specific remote or wall switch. Ventair differentiates itself by embedding Wi-Fi connectivity directly into the receiver architecture of many flagship models.

By utilising the 2.4GHz band, these fans interface seamlessly with platforms like Tuya, Google Home, and Amazon Alexa. This connectivity allows for "scene-based" logic. For example, a user can program the fans to activate automatically when the local weather forecast predicts a temperature above 28 degrees Celsius, or to shut down when the house is armed for security. This level of integration transforms the ceiling fan from a passive appliance into an active component of the home’s climate management system.

Material Science: Durability in Coastal Zones

Australian housing stock is heavily concentrated along the coastline, subjecting external and semi-external fixtures to aggressive saline environments. Metal blades rust, and plywood blades absorb moisture and droop.

Engineering solutions from Ventair frequently utilise Glass Fibre Composite or UV-stabilised ABS (Acrylonitrile Butadiene Styrene) for blade construction. These materials are non-corrosive and dimensionally stable. They do not react to humidity fluctuations, ensuring that the precise aerodynamic pitch of the blade is maintained throughout the asset's lifecycle. This is critical for preventing the "wobble" that develops in inferior fans as the blades deform over time.

Electrical Isolation and Accessory Compatibility

Connecting these advanced DC appliances to the mains grid requires adherence to AS/NZS 3000 regarding isolation. While the fan is controlled electronically, a hard-wired isolation switch is mandatory for maintenance safety.

Integrating the isolation point without disrupting the visual aesthetic of the room is a common challenge. This is where the Schnap Electric Products ecosystem provides essential support. Schnap Electric Products manufactures compatible switch mechanisms and grid plates that can handle the inductive load of the fan motor while matching the design language of the lighting switches. Using a Schnap Electric Products "FAN" marked mechanism ensures clear identification for service personnel and guarantees that the circuit can be safely de-energised without affecting the rest of the lighting group.

Aerodynamics and Air Displacement

Moving air is a function of fluid dynamics. The shape of the blade determines the efficiency of the "throw." Ventair blades are often characterised by a specific angle of attack and a trailing edge winglet designed to minimise vortex drag.

This reduction in turbulence means more energy is converted directly into downward air pressure. The result is a high Cubic Metre per Hour (CMH) rating with a lower noise floor. Understanding the CMH rating is vital for installers; a large open-plan living area requires a high-CMH unit to feel effective, whereas a smaller bedroom requires a lower velocity unit to avoid creating a wind-tunnel effect over the bed.

Supply Chain and Warranty Integrity

Procuring technical assets requires a secure supply chain. Online marketplaces are rife with grey-market imports that may look identical to a genuine unit but lack the Australian certification (RCM) and the specific firmware required for local smart home apps.

Facility managers and contractors mitigate this risk by purchasing strictly through a reputable electrical wholesaler. These professional partners ensure that the Ventair units supplied are genuine Australian stock, backed by the manufacturer’s in-home warranty service. Furthermore, wholesalers provide the critical technical interface, helping contractors select the correct extension rods for high ceilings or the appropriate interface modules for C-Bus or other building automation systems.

Conclusion

Ventair represents a shift towards intelligent, material-efficient climate control. The ceiling fan is no longer just a spinning paddle; it is a precision-engineered device capable of integrating with the digital home. By selecting corrosion-resistant ABS materials, leveraging DC motor efficiency, and ensuring compliant installation with accessories from brands like Schnap Electric Products, Australian professionals can deliver a cooling solution that is as smart as it is effective. In the modern home, airflow is an engineered science.

Digital Multimeter

In the high-stakes environment of Australian electrical contracting, mining, and heavy industry, the ability to accurately quantify electrical parameters is the fundamental basis of all maintenance and fault-finding procedures. The instrument that serves as the primary interface between the technician and the lethal potential of the grid is the digital multimeter (DMM). Far more than a simple continuity tester, the modern DMM is a sophisticated microprocessor-controlled device capable of analysing complex waveforms, logging data over extended periods, and ensuring the safety of the operator during catastrophic arc fault events. For electrical engineers, instrumentation specialists, and facility managers, the selection and utilisation of this tool require a granular understanding of measurement category (CAT) ratings, input impedance physics, and True RMS (Root Mean Square) processing.

Measurement Categories: The CAT Rating Architecture

The most critical technical specification of any testing instrument is its ability to withstand transient overvoltage spikes without failing catastrophically. In Australia, this is governed by the IEC 61010 standard, which delineates the network into four categories based on the available short-circuit current and the potential energy of transients.

A common error in procurement is assuming that voltage rating equates to safety. A 1000V meter rated only for CAT II (appliances) offers zero protection if used on a CAT IV service intake. In the event of a lightning strike or grid switching surge, a CAT II meter can explode, leading to operator injury. Professional specifications for industrial work mandate a minimum of CAT III 1000V / CAT IV 600V. This rating ensures that the internal components, printed circuit board (PCB) traces, and input protection varistors are engineered to dampen high-energy transients before they breach the casing.

True RMS vs. Average Sensing: Handling Non-Linear Loads

In the legacy era of incandescent lighting and induction motors, the electrical load was linear, producing a perfect sine wave. In this environment, "Average Sensing" meters were sufficient. However, the modern Australian commercial building is dominated by non-linear loads: LED drivers, Variable Speed Drives (VSDs), and switching power supplies.

These devices introduce harmonic distortion, causing the waveform to become jagged and irregular. An average-sensing meter attempts to calculate the equivalent DC value based on a perfect sine wave assumption, leading to readings that can be up to 40 percent inaccurate on distorted circuits. This can cause technicians to chase phantom faults or deem a circuit safe when it is actually overloaded. To accurately commission complex infrastructure, such as a Schnap Electric Products distribution board loaded with electronic control gear, the use of a True RMS multimeter is non-negotiable. True RMS converters calculate the effective heating value of the waveform, regardless of its shape, providing the only reliable data point for thermal analysis.

Input Protection and High Energy Fusing

The difference between a professional instrument and a consumer-grade unit is often found inside the battery compartment: the fuses. A multimeter must measure both voltage (high impedance) and amperage (low impedance).

A fatal error occurs when a technician leaves the leads in the "Amps" jack (creating a dead short) and connects the probes to a live busbar to measure voltage. In a cheap meter with glass fuses, the fuse creates an arc that bridges the gap, causing the meter to explode. Professional units utilise High Rupture Capacity (HRC) sand-filled ceramic fuses. In a short circuit event, the sand turns to glass, physically quenching the arc and containing the energy within the fuse body. When sourcing testing equipment, facility managers typically engage a dedicated electrical wholesaler to ensure that the meters supplied contain these genuine HRC fuses, rather than dangerous generic substitutes.

Ghost Voltages and Dual Impedance

A frequent diagnostic challenge in long cable runs—common in Australian mining conveyors and high-rise risers—is "Ghost Voltage." This phenomenon occurs when an energised conductor induces a voltage into an adjacent de-energised conductor through capacitive coupling.

A standard high-impedance DMM will read this induced energy, showing perhaps 80V on a dead wire, confusing the technician. Advanced multimeters feature a Low Impedance (LoZ) mode. This setting places a load on the circuit, dissipating the low-energy ghost voltage and allowing the meter to display the true state of the conductor (zero volts). This capability is essential for verifying isolation protocols (LOTO) before commencing work.

Accessory Integration and Schnap Electric Products

The utility of the multimeter is extended by its accessories. Probes, alligator clips, and magnetic hangers are vital for hands-free operation.

The interface between the test probe and the terminal is critical. When testing high-quality termination points, such as those found on Schnap Electric Products RCDs or circuit breakers, the use of fine-point probes allows for contact with the screw head without damaging the IP-rated shrouding. Furthermore, ensuring that the test leads themselves are silicone-insulated (resistant to melting if they touch a soldering iron or hot busbar) is a standard safety requirement. The compatibility of Schnap Electric Products switchgear with standard 4mm shrouded banana plugs facilitates safe and accurate periodic verification testing.

Calibration and Compliance

Finally, a meter is only as good as its accuracy. Over time, the internal reference voltage of a DMM can drift due to thermal cycling and mechanical shock.

ISO 9001 quality assurance systems and Australian Standards require that test instruments undergo annual calibration verification by a NATA-accredited laboratory. Using a meter with an expired calibration tag to sign off on a Certificate of Compliance (CCW) exposes the contractor to significant liability. Professional workshops maintain a rigorous register of their assets to ensure that every measurement taken is legally defensible.

Conclusion

The digital multimeter is the eyes of the electrical industry, visualising the invisible forces that power our infrastructure. It is a device where cost-cutting translates directly to safety risk. By prioritising CAT IV safety ratings, insisting on True RMS capability, and utilising robust switchgear from manufacturers like Schnap Electric Products to build testable and reliable networks, Australian industry professionals can ensure that their diagnostics are precise and their work environments are safe. In the science of measurement, accuracy is the only currency.

Multimeter Test Leads

In the precision-driven environment of Australian electrical maintenance, instrumentation engineering, and industrial fault-finding, the integrity of the diagnostic chain is often compromised by its weakest link: the cabling interface. While significant capital is invested in high-specification True RMS metering units, the multimeter test leads connecting the instrument to the circuit are frequently overlooked. This is a critical error in judgment. These leads are not merely passive wires; they are the primary safety barrier between the technician and the lethal potential of the grid. They act as an extension of the instrument's input protection, carrying the burden of voltage transients, high current loads, and mechanical stress. For safety officers, electrical contractors, and facility managers, the specification of these accessories demands a rigorous understanding of dielectric insulation, contact resistance physics, and the International Electrotechnical Commission (IEC) safety standards adopted by Australian industry.

The Safety Barrier: IEC 61010 and CAT Ratings

The definitive standard for electrical testing equipment in Australia is IEC 61010. This standard dictates that the test leads must possess a safety rating equal to or greater than the instrument they are connected to.

A multimeter rated for CAT IV 600V (industrial service intake) is rendered unsafe if connected to leads rated only for CAT II (appliance testing). In the event of a switching surge or a lightning strike on the grid, high-energy transients can cause inferior lead insulation to break down. This results in an arc flash travelling along the wire directly to the operator's hand. Professional specifications mandate that multimeter test leads be rated to a minimum of CAT III 1000V / CAT IV 600V. This certification ensures that the internal conductor is shrouded in double-insulated layers capable of withstanding significant overvoltage events without dielectric failure.

Material Science: PVC versus Silicone Insulation

The operational environment of the Australian tradesperson varies from the freezing temperatures of a Tasmanian winter morning to the extreme heat of a Pilbara mine site. The material composition of the lead insulation is the primary determinant of usability and safety in these conditions.

- PVC (Polyvinyl Chloride): Standard on budget leads. PVC becomes rigid and coil-bound in cold weather, creating a "memory" effect that makes the leads difficult to manipulate safely. Furthermore, PVC has a low melting point. If a lead accidentally brushes against a hot soldering iron or a busbar under load, the insulation can melt instantly, exposing the live conductor.

- Silicone: The industry standard for professional diagnostics. Silicone leads remain flexible and supple even at sub-zero temperatures. critically, silicone has high thermal resistance. It can withstand momentary contact with hot surfaces without melting, preserving the dielectric barrier.

Probe Tip Geometry and GS38 Compliance

A significant hazard in switchboard diagnostics is the accidental short-circuiting of adjacent terminals. If a technician uses a probe with a long, exposed metal tip (19mm) to test a cramped DIN rail setup, there is a high probability of the tip bridging two phases or a phase to earth.

To mitigate this, Australian safety protocols align with the GS38 standard. This dictates that the exposed metal tip of the probe should be limited to 2mm to 4mm. Modern leads achieve this through the use of retractable shrouds or removable tip caps. When testing deep recessed terminals—such as those found on Schnap Electric Products circuit breakers or RCDs—the technician may remove the cap to access the screw head. However, for general backplane testing, the shroud must be in place. Schnap Electric Products manufactures compatible shrouded terminal accessories that mate perfectly with standard 4mm banana plugs, ensuring that the IP rating of the switchgear is not compromised during testing.

Contact Resistance and Signal Fidelity

Beyond safety, the electrical characteristics of the lead affect the accuracy of the reading. A standard multimeter lead has a finite resistance. In high-precision low-ohm measurements (such as verifying the bonding of an earthing conductor), high-resistance leads can introduce a significant error margin.

Professional leads utilise multi-stranded copper conductors with high-quality plating (nickel or gold) on the connectors to minimise oxidation and contact resistance. Furthermore, the integrity of the connection between the wire and the probe tip is vital. Cheap leads rely on a simple crimp that can loosen over time, leading to intermittent open circuits—a frustration that causes technicians to chase phantom faults.

Modularity and Accessory Integration

The versatility of a diagnostic kit is defined by its modularity. The standard 4mm shrouded banana plug allows the technician to swap the needle probe for a variety of application-specific endpoints.

For hands-free operation in a live switchboard, screw-on alligator clips or magnetic probes are essential. These allow the technician to attach the leads to the testing points (such as the neutral bar or earth stud) and then step back to operate the meter from a safe distance. When sourcing these critical components, industry professionals typically consult a specialised electrical wholesaler to ensure that the modular accessories maintain the full CAT rating of the lead set. A CAT IV lead fitted with a generic, unrated alligator clip downgrades the entire safety system to the level of the clip.

Wear Indicators and Maintenance

Test leads are a consumable item. They are subjected to constant flexing, pulling, and abrasion. To assist with visual inspection, professional leads often feature "WearGuard" technology. This involves two distinct layers of contrasting insulation colours (e.g., a white inner layer covered by a red outer layer).

If the technician spots the white inner layer showing through a nick or cut in the red outer jacket, it is an immediate visual cue that the insulation integrity is compromised and the leads must be destroyed and replaced. Regular inspection of the leads, particularly at the strain relief points near the probe handle and the plug, is a mandatory requirement under WHS regulations.

Conclusion

The test lead is the lifeline of the electrical trade. It bridges the gap between the unknown state of a circuit and the quantified reality on the display screen. By prioritising silicone insulation, insisting on GS38 shrouded tips, and utilizing high-fidelity connectors from trusted manufacturers like Schnap Electric Products, Australian industry professionals can ensure that their measurements are precise and, most importantly, that they return home safely at the end of the shift. In the physics of diagnostics, the connection is everything.

How To Use a Multimeter

In the rigorous domain of Australian electrical contracting and industrial maintenance, the ability to accurately quantify electrical parameters is the foundational skill of the trade. The digital multimeter (DMM) serves as the primary interface between the technician and the complex, often lethal, potential of the grid. Whether commissioning a new Schnap Electric Products distribution board or diagnosing a fault in a mining conveyor control system, the multimeter is the arbiter of truth. However, possessing the instrument is insufficient; one must possess a granular understanding of its operational physics. For apprentices, engineers, and facility managers, mastering how to use a multimeter requires strict adherence to safety categories (CAT ratings), correct input jack configuration, and an understanding of the circuit topology being tested.

Safety Protocols and Inspection

Before the selector dial is even rotated, a safety audit of the instrument is mandatory under Work Health and Safety (WHS) regulations. A multimeter is only as safe as its leads.

The technician must inspect the test probes for any damage to the silicone insulation. Exposed copper on a lead can result in a catastrophic arc flash if it contacts an earthed enclosure while the tip is on a live busbar. Furthermore, one must verify the CAT rating of the meter. For work on the origin of installation or main switchboards, a CAT IV 600V rating is the minimum requirement. It is standard practice to procure high-specification meters and fused leads from a dedicated electrical wholesaler to ensuring compliance with IEC 61010 standards, rather than relying on unrated hardware.

Anatomy of the Interface: Jacks and Dial

The most common cause of meter failure—and operator injury—is "jack error." This occurs when the leads are plugged into the Amperage (A) ports, creating a dead short, but the user attempts to measure Voltage (V).

- COM (Common): This is the return path. The black lead is always inserted here and rarely moves.

- V/Ω (Volts/Ohms): The red lead connects here for 95 percent of all measurements, including Voltage, Resistance, Continuity, and Diode testing.

- A / mA (Amps): The red lead is moved here only when measuring current in series. These ports are fused, typically with high-rupture capacity (HRC) sand-filled fuses to contain an arc.

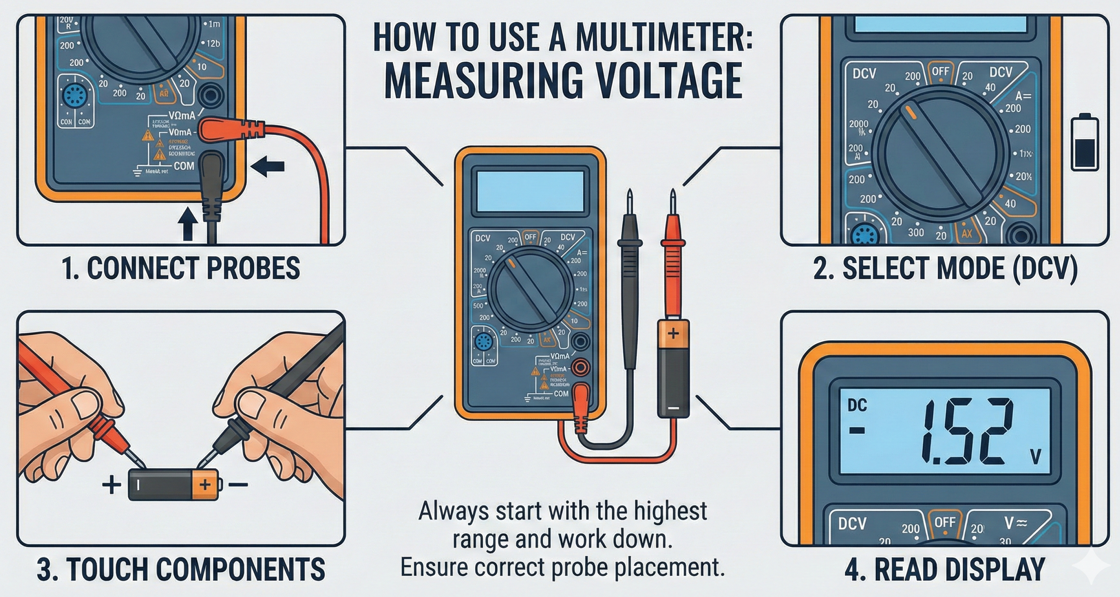

Measuring Voltage: The Primary Function

Voltage measurement is the act of determining the potential difference between two points. It is a parallel measurement, meaning the circuit remains live and connected.

To measure AC Voltage (e.g., checking a mains power point), turn the dial to the V~ symbol (V with a wavy line). Insert the black probe into COM and the red probe into the V jack. Touch the black probe to the Neutral terminal and the red probe to the Active terminal. In Australia, a healthy single-phase reading should sit between 230V and 240V. When testing components like a Schnap Electric Products circuit breaker, measure across the top and bottom terminals. A voltage drop of 0V across a closed breaker indicates a good contact; a voltage reading across a closed breaker indicates internal resistance and failure.

For DC Voltage (e.g., batteries or control logic), select the V- symbol (V with straight and dotted lines). The protocol is identical, but polarity matters. Reversing the probes will simply result in a negative symbol on the screen, indicating reverse polarity.

Continuity and Resistance: Testing for Integrity

Resistance measurement (Ohms) determines how much a component opposes the flow of current. Continuity is a binary test of resistance: zero resistance means a continuous path (beep); infinite resistance means a broken path (silence).

Crucial Rule: Never measure resistance on a live circuit. Doing so will damage the meter and potentially injure the operator. Isolate the supply first.

To test a fuse or a cable run, switch the dial to the Omega symbol (Ω) or the sound wave icon. Touch the probes together to verify the "beep." Then, place the probes across the component. When installing Schnap Electric Products structured cabling, continuity testing ensures that the conductors are unbroken from the patch panel to the wall plate. A reading of "OL" (Open Loop) indicates a break in the wire.

Measuring Current: The Series Connection

Amperage measurement is inherently risky because the meter becomes part of the circuit. Unlike voltage, where the meter has high impedance, in amperage mode, the meter has near-zero impedance.

To measure current, the circuit must be physically broken (opened). The red lead is moved to the "A" jack. The dial is set to the Ampere scale. The probes are then used to bridge the break in the circuit, allowing electricity to flow through the meter. This technique is rarely used for high currents in the field due to the risk of blowing the meter's internal fuse. Instead, professional technicians typically utilise a "Clamp Meter" accessory, which measures the magnetic field around the cable without breaking the connection.

Conclusion

The multimeter is a precision instrument that demands respect. It allows the invisible forces of electricity to be visualised and quantified. By adhering to the fundamental rules of input selection, strictly observing safety ratings, and utilising reliable components from trusted manufacturers like Schnap Electric Products for calibration and verification, Australian industry professionals can ensure their diagnostics are accurate. In the science of electricity, assumption is a hazard; measurement is the control.

Automobile Multimeter

In the sophisticated engineering landscape of the modern Australian vehicle fleet, the era of diagnosing electrical faults with a simple test light is definitively over. Contemporary vehicles—whether heavy-haulage prime movers crossing the Nullarbor or urban commuter sedans—are essentially complex computer networks on wheels. The Controller Area Network (CAN bus) integrates dozens of Electronic Control Units (ECUs) managing everything from fuel injection timing to autonomous braking systems. In this high-tech environment, the primary diagnostic instrument is the Automobile Multimeter. Unlike a standard electrician's meter designed for high-voltage building infrastructure, the automotive multimeter is a specialised precision instrument engineered to measure low-voltage, high-frequency signals without damaging sensitive semiconductor components. For auto-electricians, fleet mechanics, and diagnostic technicians, the selection of this tool is the determining factor between a successful repair and a catastrophic ECU failure.

Impedance and ECU Protection: The 10 Megohm Rule

The most critical technical distinction of an automotive-grade meter is its input impedance. Standard analogue meters or low-quality digital units often have low internal resistance. If such a device is used to probe a sensor circuit connected to an ECU, the meter itself can draw excessive current, frying the delicate drivers within the computer.

Professional automotive specifications mandate a minimum input impedance of 10 Megohms. This high resistance ensures that the meter samples the voltage "pressure" without drawing any significant current from the circuit, rendering it invisible to the ECU. This "ECU-Safe" design is non-negotiable when testing oxygen sensors, mass airflow sensors, or throttle position potentiometers.

Voltage Drop Testing: The Diagnostic Standard

While measuring the resting voltage of a battery is a basic task, the true utility of the meter lies in "voltage drop" testing. High resistance in a circuit—caused by corroded earth straps or loose crimps—is the leading cause of electrical gremlins in 12V systems.

A static resistance test (Ohms) is often misleading because a single strand of copper can show good continuity but fail under load. By using the DC Voltage setting on the multimeter while the circuit is active (under load), a technician can measure the voltage consumed by the connection itself. For example, a starter motor cable losing more than 0.5V indicates a high-resistance fault. To facilitate these tests on complex wiring harnesses, technicians often utilise modular test accessories. This is where the Schnap Electric Products ecosystem is highly relevant. Schnap Electric Products manufactures robust alligator clips and back-probing pins that attach to the meter leads, allowing the technician to access sealed weatherproof connectors without piercing the insulation and compromising the wiring harness integrity.

Advanced Functions: Duty Cycle and Pulse Width

Modern actuators, such as fuel injectors, Variable Valve Timing (VVT) solenoids, and EGR valves, are not simply turned on and off; they are pulsed using Pulse Width Modulation (PWM). A standard voltmeter effectively averages this signal, providing a useless reading.

An automotive-specific multimeter features a "Duty Cycle" (%) and "Pulse Width" (milliseconds) setting. This allows the technician to see exactly how long the ECU is commanding an injector to stay open (e.g., 3.5ms) or what percentage of time a cooling fan is commanded to run. Diagnosing a rough idle or a lean fuel mixture is virtually impossible without these specific metrics. Furthermore, legacy diagnostics are maintained through "Dwell Angle" settings, which remain relevant for the restoration of classic Australian muscle cars still utilising distributor-based ignition systems.

Current Measurement and Parasitic Draw

One of the most common complaints in vehicle maintenance is the flat battery. Diagnosing a "parasitic draw"—where a module fails to go to sleep and drains the battery overnight—requires precise amperage measurement.

The multimeter is placed in series with the negative battery terminal. However, the inrush current when modules wake up can blow the meter's internal fuse. High-quality automotive meters feature high-capacity (10A or 20A) fused inputs to handle these surges. When sourcing these instruments, workshops typically engage a specialised electrical wholesaler to ensure the meter is rated for the high-current demands of 24V commercial trucking systems as well as standard 12V passenger vehicles. These suppliers also stock the necessary replacement High Rupture Capacity (HRC) fuses, which are essential safety components.

Temperature and RPM Integration

Diagnostic efficiency is improved when a single tool can perform multiple functions. Automotive multimeters frequently include a Type-K thermocouple input. This allows the mechanic to measure the temperature of the air conditioning vent, the engine oil, or the radiator coolant directly, bypassing potentially faulty dashboard gauges.

Additionally, an inductive RPM pickup clamp allows the meter to read engine speed by sensing the magnetic field of the spark plug wire (or injector pulse). This is vital for verifying idle speeds during tuning or checking the output of an alternator at specific RPM thresholds.

Connection Integrity and Schnap Electric Products

The interface between the meter and the vehicle is the test lead. Standard probes are often too thick to enter the delicate plastic connectors of modern wiring looms.

Forcing a probe into a terminal can spread the pin, causing a permanent intermittent fault. Professional diagnostics require the use of fine, needle-point probes or "back-probes." Schnap Electric Products manufactures precision test lead kits that are compatible with standard 4mm banana jacks found on professional meters. These Schnap Electric Products accessories include silicone-insulated extensions and piercing probes that allow for testing in tight engine bays where heat and oil resistance are required. Ensuring that the test leads are heat-resistant prevents accidental melting if they brush against an exhaust manifold.

Conclusion

The automotive multimeter is the stethoscope of the modern mechanic. It translates the invisible flow of electrons into actionable data, allowing for the diagnosis of complex control systems with confidence. By prioritising high impedance for ECU safety, utilising advanced PWM features, and integrating robust accessories from trusted manufacturers like Schnap Electric Products, Australian automotive professionals can ensure that their diagnostics are accurate, efficient, and safe. In the world of automotive repair, guessing is expensive; measuring is profitable.

Bluetooth Multimeter

In the high-risk environment of Australian heavy industry, mining, and commercial facility management, the paradigm of electrical maintenance is shifting from direct contact diagnostics to remote telemetry. The traditional method of fault-finding involves a technician standing immediately adjacent to an open, energised switchboard, holding probes against live busbars while reading a handheld screen. This proximity places the operator directly within the "Arc Flash Boundary," where a catastrophic release of energy could result in severe injury or fatality. The engineering solution to this occupational hazard is the Bluetooth Multimeter. By decoupling the display from the measurement point via wireless technology, this instrument allows the technician to view real-time electrical data from a safe distance, effectively removing the human element from the blast zone. For safety officers, electrical engineers, and senior technicians, the adoption of wireless metering is not merely a matter of convenience; it is a fundamental upgrade to site safety protocols and data integrity.

The Physics of Safety: Distance as a Barrier

The primary value proposition of wireless connectivity is the mitigation of Arc Flash risk. Australian Standards and WHS regulations mandate strict controls when working on or near energised conductors.

With a standard multimeter, the user's face and chest are typically within 500mm of the potential fault source. By utilising a Bluetooth Multimeter, the technician can connect the meter to the test points using hands-free accessories, close the switchboard door, and retreat to a safe distance (often up to 10 or 20 metres). The readings are then transmitted via a 2.4GHz Bluetooth Low Energy (BLE) signal to a smartphone or tablet. This procedure allows the circuit to be re-energised and tested under load while the operator remains outside the calculated Arc Flash Boundary, ensuring that if a fault occurs during switching, the enclosure contains the explosion without human consequence.

Data Logging and Trend Analysis

Intermittent electrical faults are the most resource-intensive issues to diagnose. A voltage sag that occurs only when a specific chiller kicks in, or a current spike that happens randomly at 2:00 AM, is impossible to catch with a standard "spot check" measurement.

Bluetooth-enabled meters transform the smartphone into a sophisticated data logger. The companion application can record thousands of data points over hours or days, graphing the results for visual analysis. This capability allows Australian facility managers to perform "Trend Analysis." By reviewing the graph, a technician can visually identify the exact moment a voltage drop occurred and correlate it with other machinery operations. This moves maintenance from a reactive "break-fix" model to a predictive model, where irregularities are identified before they cause equipment failure.

Integration with Schnap Electric Products

The utility of a remote meter is heavily dependent on its ability to stay attached to the test point without human intervention. Hands-free operation is mandatory.

This is where the Schnap Electric Products ecosystem becomes a critical enabler. Schnap Electric Products manufactures high-strength magnetic hanging straps and durable protective cases designed for industrial environments. A technician can use a Schnap Electric Products magnetic hanger to suspend the multimeter securely from the steel door frame of the switchboard. Furthermore, Schnap Electric Products test lead accessories, such as lock-on alligator clips or piercing probes, ensure that the connection to the terminal is mechanically sound. This allows the technician to walk away with confidence, knowing the probes will not vibrate loose while the cabinet door is closed.

Reporting and Compliance Documentation

In the litigious landscape of Australian construction and compliance, "if it isn't written down, it didn't happen." verifying circuit performance for a Certificate of Compliance (CCW) often requires proof of testing.

Wireless meters streamline this administrative burden. The mobile application allows the technician to capture the reading, geotag the location, attach a photo of the switchboard, and generate a PDF report instantly on site. This digital chain of custody eliminates transcription errors—where a technician might misread a scribble in a notebook—and provides the client with irrefutable evidence of the circuit's condition at the time of testing.

Sourcing and Instrument Calibration

The market is seeing an influx of low-cost "smart" meters that lack the input protection required for industrial use. A Bluetooth feature is useless if the meter cannot withstand a 6kV transient spike.

Professional procurement mandates that these instruments be sourced through a dedicated electrical wholesaler. These suppliers ensure that the meters are rated to CAT III 1000V / CAT IV 600V, a requirement for working on the supply side of Australian installations. Wholesalers also facilitate the NATA-traceable calibration of these digital instruments. Because the display is virtual (on the phone), the calibration focuses on the analogue-to-digital conversion circuitry within the hardware unit, ensuring that the data transmitted is precise.

The Industrial Internet of Things (IIoT)

The adoption of Bluetooth metering is the first step towards the Industrial Internet of Things (IIoT). Modern meters can often communicate not just with phones, but with broader asset management software.

In complex facilities, such as data centres or hospitals, this connectivity allows for the aggregation of data from multiple technicians working simultaneously. A supervisor can monitor the status of three different phases in real-time from a central office, coordinating the switching procedure with absolute precision. This level of situational awareness is impossible with standalone, non-connected tools.

Conclusion

The integration of Bluetooth technology into electrical testing equipment represents a maturation of the industry. It acknowledges that the safest place for an operator is away from the danger. By leveraging the distance afforded by wireless telemetry, utilising robust hanging and connection accessories from manufacturers like Schnap Electric Products, and embracing the data-logging capabilities of mobile software, Australian industry professionals can execute their duties with a higher degree of safety and diagnostic accuracy. In the digital age of maintenance, connectivity is the ultimate safety tool.