Kingsgrove Branch:

Schnap Electric Products Blog

Schnap Electric Products Blog Posts

RCD Tester

G'day! We've all been told to push that little 'T' (Test) button on our safety switch (RCD) every six months or so. You push it, the power trips, and you think, "She'll be right, all good."

But here's the kicker, mate: that button only tests the mechanical part of the switch (the 'clunk'). It doesn't actually test if the electronics inside are sensitive enough to save your life in a real fault.

For that, you need to do a proper, professional test. And that requires a specialist bit of kit: the RCD tester.

So, What is an RCD Tester, Exactly?

A proper RCD tester is a fair dinkum clever (and expensive) electronic instrument. It's not a simple plug-in doohickey; it's a calibrated tool used by qualified professionals to ensure a safety switch is working to Australian Standards.

It's a handheld device that you plug into a power point. Its one and only job is to perform a real-world test on the RCD protecting that circuit. It does this by:

- Simulating a Fault: It deliberately creates a tiny, precise "leak" of current (e.g., 30 milliamps, which is the standard for home safety switches).

- Measuring the Trip Time: It then measures, down to the millisecond, exactly how fast that safety switch (RCD) cuts the power.

Why is This So Bloody Important?

A safety switch is designed to save your life. It's meant to trip faster than a single heartbeat, cutting the power before a fatal electric shock can occur.

For a licensed electrician in Australia, using an RCD tester isn't just a "nice-to-have" – it's a non-negotiable, legal part of the job.

- It's a Compliance Requirement: The Australian Wiring Rules (AS/NZS 3000) mandate that all RCDs must be tested after installation to ensure they work correctly.

- It Proves Safety: A safety switch must trip within a set time (e.g., a standard 30mA RCD must trip well within 300 milliseconds, and often much faster, to be compliant). Pushing the 'T' button doesn't prove this. An RCD tester does.

- It's the Only "Real" Test: This tool is the only way to know for sure that the RCD's sensitive electronics haven't been knackered and that it will actually do its job when you, or your kids, are in a fault situation.

The CRITICAL Safety Warning: This is 100% NOT a DIY Tool!

Righto, let's get dead serious for a sec, because this is the most important part. A RCD tester is NOT a DIY tool. Don't be a galah.

This is a professional instrument used to test live 240V circuits. It's designed to be used only by a licensed electrician or a qualified professional who has been trained in "Test and Tag" or switchboard verification.

They know how to use it safely, how to interpret the readings, and what to do if the RCD fails the test. Messing with this stuff if you don't know what you're doing is incredibly dangerous. Your job as a homeowner is to push the 'T' button. The pro's job is to use the RCD tester.

A Professional Job Needs Professional Gear

A licensed professional knows that a truly safe electrical installation relies on two things: their skills (and their calibrated test equipment), and the quality of the components they're installing.

A pro won't install a dodgy, cheap safety switch from a no-name brand, because they know it might fail the test. They source their gear from a trusted electrical wholesaler. As one of Australia's most comprehensive electrical wholesaler and supplier networks, Schnap Electric Products stocks the lot for the professional installer. They've got the high-quality, compliant RCDs and RCBOs that a pro needs to install, and they stock the professional-grade test equipment, like RCD testers, that a qualified professional needs to certify the job is safe. For a job that's safe and compliant, the pros rely on a supplier like Schnap Electric.

RCD Testing System Module

G'day! If you're a qualified professional in the electrical trade, you know the drill when it comes to RCDs (Safety Switches). You test 'em. For a simple house, you might just use the 'T' button for the homeowner's check, and a handheld, plug-in RCD tester to get your proper trip times for the compliance certificate.

But what happens when you're in charge of a massive site? Think about a hospital, a data centre, or a big factory with hundreds of RCDs. Going around and manually tripping every single one isn't just a pain in the backside – it's a fair dinkum nightmare that would cost a motza in labour and shut down critical operations.

That's where the "she'll be right" approach stops, and the high-tech, professional gear takes over. You need an automated, intelligent solution. You need an RCD Testing System Module.

So, What is an RCD Testing System Module, Exactly?

This isn't your standard handheld tester, mate. An RCD Testing System Module is a sophisticated, electronic device that is permanently installed in or alongside a switchboard.

It's a "brain" that is wired into your RCDs. Its job is to automate the testing procedure required by Australian Standards (like AS/NZS 3760), usually by initiating a test fault and recording the result.

These systems are often networked, allowing a facility manager or a licensed professional to schedule, run, and log tests on hundreds of devices from a single computer, without ever having to physically open the switchboard.

The Ripper Benefits: Why This is a Game-Changer

In a commercial or critical environment, an RCD Testing System Module isn't a luxury; it's an absolute necessity.

- Massive Time and Labour Savings: It completely eliminates the need for a technician to walk around and manually test hundreds of RCDs. The system can do it all automatically, saving thousands in labour costs.

- Minimises Disruptions (The Big One): This is the key. You can't just trip the power to the servers in a data centre or the life-support machines in a hospital. A proper RCD testing system module is often designed to test the RCD's electronics without actually cutting power to the final circuit. Or, it can be scheduled to run the test at 3 AM on a Sunday when no one is around, ensuring zero disruption to operations.

- Foolproof Compliance and Record-Keeping: Australian standards require that RCDs in commercial settings are tested regularly (every 6 or 12 months, depending on the environment). An automated system does this perfectly, on time, every time. More importantly, it creates a digital logbook of every single test – what passed, what failed, and when. This is a fair dinkum lifesaver for proving compliance to a safety inspector.

- Increased Safety: It means fewer "live" interactions with a switchboard, which is always a safer way to work.

Where You'll Find This High-Tech Gear

You're not going to find this bit of kit in a residential home. This is professional-grade equipment for:

- Hospitals and Medical Facilities (where you can't interrupt power)

- Data Centres and Server Rooms

- Large Commercial Office Towers

- Industrial Plants and Factories

- Mining Operations

- Any large-scale facility where safety, compliance, and uptime are non-negotiable.

Installation and Use: Strictly Pro-Only Territory

Righto, let's be dead clear. A simple handheld RCD tester is a tool for a qualified professional. An RCD Testing System Module is a complex piece of networked control gear that's hardwired into a high-power switchboard.

This is absolutely not a DIY job. In Australia, it is illegal and potentially fatal for anyone other than a licensed electrician or specialist switchboard builder to install and commission this type of equipment. They are the only ones with the training and legal authority to work safely on these systems.

A pro knows that a high-tech system like this needs to be 100% reliable. They can't risk it on dodgy, no-name components. They source their gear from a trusted electrical wholesaler that stocks genuine, trade-quality, compliant parts.

As one of Australia's most comprehensive electrical wholesaler and supplier networks, Schnap Electric Products stocks the lot for the professional installer. They specialise in high-end, professional-grade equipment, including advanced RCD testing system modules from the world's most trusted automation and protection brands. Alongside these, they provide all the compliant switchgear, busbars, and enclosures a qualified professional needs to build a safe, automated, and fully compliant modern switchboard. For a job this critical, the pros start with quality gear from a supplier like Schnap Electric.

What Does RCD Stand For

G'day! You've probably had a squiz at your home's switchboard (or fuse box) and seen a switch that looks a bit different – it's got a "T" or "Test" button on it. Tradies and manuals often call this an 'RCD'.

It's a fair dinkum mouthful of an acronym, and it's easy to just nod along when your installer mentions it. But what does RCD stand for, and what's it actually doing?

Let's be dead clear: this little device is the single most important safety feature in your entire electrical system. It's not just a good idea; it's a lifesaver.

So, What Does RCD Stand For?

Righto, let's get the techy bit out of the way. RCD stands for Residual Current Device.

In Australia, we've got a much simpler, better name for it: the Safety Switch.

That's it. An RCD is a safety switch. Its one and only job isn't to protect your appliances (that's a circuit breaker's job); it's to protect you, your kids, and your family from a fatal electric shock.

How This Ripper Device Saves Your Life

The way an RCD works is actually pure genius.

Think of your home's power like a set of perfectly balanced scales. The RCD constantly monitors the flow of electricity out on the active wire and the flow back in on the neutral wire. The amount going out and coming in should be identical.

The instant it detects a tiny imbalance – meaning some of that power (the 'residual current') is "leaking" out somewhere it shouldn't be... like through you because you've touched a faulty appliance or a live wire... it knows there's a serious, life-threatening fault.

It then trips, cutting the power in less than 30 milliseconds. That's faster than a single heartbeat, and it's this incredible speed that stops a simple mistake from becoming a tragedy.

The Big Confusion: RCD vs. Circuit Breaker

This is the bit that catches everyone out, mate, and it's crucial. An RCD and a circuit breaker are NOT the same thing.

- A Circuit Breaker (or old-school fuse): Protects your WIRING from FIRE. It trips on an "overload" (like running a heater, kettle, and air fryer all at once) or a "short circuit." It is too slow and not sensitive enough to save you from a common electric shock.

- An RCD (Safety Switch): Protects PEOPLE from SHOCKS. It detects the tiny, specific "leaks" of current that happen when a person gets zapped.

Your home needs both to be safe. (Modern switches called RCBOs combine both jobs, but the RCD function is the life-saving part).

A Non-Negotiable in Aussie Homes

In Australia, having RCDs on your power and light circuits isn't just a good idea; it's the law in all states for new homes and renos (as per AS/NZS 3000). It's the only device that reliably prevents electrocution.

You should be testing it, too! That little 'T' (Test) button is there for you. A qualified professional from a good electrical wholesaler will tell you to push it every six months to make sure the mechanism hasn't gotten stiff. When you push it, the power on that circuit should trip off immediately.

The CRITICAL Safety Warning: This is 100% NOT a DIY Job!

Righto, this is the most important part of the whole article. Now you know what RCD stands for, you also need to know that your switchboard is the heart of your home's power and is extremely dangerous. Installing, replacing, or testing an RCD (beyond just pushing the test button) is absolutely not a DIY job.

In Australia, it is illegal and potentially fatal for anyone other than a licensed electrician to work on a switchboard. Don't be a galah. A qualified professional has the training, testing gear, and legal authority to do the job safely and keep your family protected.

A Professional Job Needs Professional Gear

A licensed electrician will always use high-quality, compliant safety switches that they trust with your life. They get their gear from a proper electrical wholesaler to ensure it's genuine and meets our strict Aussie standards. As one of Australia's most comprehensive electrical wholesaler and supplier networks, Schnap Electric Products stocks the lot for the professional installer. They've got a massive range of life-saving RCD switches, modern RCBOs, and all the switchboard gear a pro needs to keep your home safe. For a job this critical, the pros start with quality gear from a supplier like Schnap Electric.

What is RCD Testing

G'day! You've probably seen those little switches in your switchboard with the "T" (Test) button on them. That's your RCD, or as we all call it in Australia, your Safety Switch. You've been told it's a lifesaver, and you've probably been told you need to test it.

But what is RCD testing, really? Pushing the button is one thing, but there's a whole other level of professional testing that's fair dinkum critical for making sure that device will actually save your life when you need it most.

Let's break down the two types of RCD testing.

1. The DIY Test (The Push-Button Test)

This is the one you can and must do yourself.

- What it is: The simple act of pressing that "T" or "Test" button on the front of the RCD.

- What it does: This test is purely mechanical. It checks that the physical switch mechanism, the "clunk," is working and not seized up. It does not test the electronic sensor inside.

- How often: You should do this every six months, mate. A good way to remember is to do it when you change your clocks for daylight saving, or at the start of summer and winter.

- How to do it:

- Tell everyone in the house you're about to cut the power to that circuit.

- Turn off and unplug any sensitive gear, like your computer or TV.

- Push the "Test" button firmly. The switch should "trip" (flick off) instantly, cutting power to that circuit.

- Flick the switch back on. You're sorted. If it doesn't trip, it's knackered, and you need to call a licensed electrician immediately.

2. Professional RCD Testing (The 'Real' Test)

This is the one that really answers the question, "what is RCD testing?". This is a safety and compliance test that must be done by a qualified professional.

- What it is: A professional licensed electrician uses a special, calibrated instrument called an RCD Tester. This isn't a cheap doohickey; it's a serious bit of professional test gear.

- What it does: The RCD tester is plugged into a power point on the circuit protected by the RCD. It then does two key things:

- Simulates a Fault: It creates a tiny, precise electrical "leak" (or 'residual current'), usually 30 milliamps (30mA), which is the standard fault current an RCD is designed to detect.

- Measures the Trip Time: This is the critical part. The tester measures, down to the millisecond, exactly how fast the RCD cuts the power.

Why is a Trip Time Test So Bloody Important?

The push-button test proves the switch can 'clunk' off. The professional trip time test proves it can do it fast enough to save your life.

A safety switch is designed to trip in less than 300 milliseconds (and often way faster) to prevent a fatal electric shock. Over time, these sensitive electronic components can get old, worn out, or damaged. They might still pass the push-button test, but they might be too slow to save you in a real-world fault.

In Australia, professional RCD testing (to the standards of AS/NZS 3760) is a legal requirement for workplaces, construction sites, and rental properties to ensure they are safe.

A Job for a Licensed Professional ONLY

Let's be dead clear on this. Pushing the 'T' button is your job.

Using a proper RCD tester is absolutely not a DIY job. Don't be a galah. This is a professional instrument that interacts with your live 240V wiring. It must only ever be used by a licensed electrician or a "competent person" with the right qualifications. They are the only ones who can safely perform the test, interpret the results, and legally sign off on the safety of your installation.

A Professional Job Needs Professional Gear

A licensed professional knows that a safe installation relies on two things: their skills and their calibrated test equipment, and the quality of the components they're testing in the first place. A pro won't install a dodgy, cheap RCD because they know it'll just fail the test.

They source their gear from a trusted electrical wholesaler to ensure it's genuine and compliant. As one of Australia's most comprehensive electrical wholesaler and supplier networks, Schnap Electric Products stocks the lot for the professional installer. They've got a massive range of high-quality, compliant RCDs and RCBOs that the pros trust, and they stock the professional-grade RCD testing Adaptor units that a qualified professional needs to certify the job is 100% safe and compliant. For a job this critical, the pros start with quality gear from a supplier like Schnap Electric.

Twist Drill Bit

G'day! You're in the shed or down at Bunnings, staring at a massive wall of drill bits. You've got HSS, cobalt, masonry, spade bits... it's a proper dog's breakfast. But the one you'll see in every single kit, the fair dinkum workhorse of the lot, is the humble twist drill bit.

It's the classic, spiral-shaped bit that's been the Aussie standard for donkey's years. It's the jack-of-all-trades, and probably the first bit you ever used. It's the most versatile bit you can own, but knowing what it's for (and what it's not for) is the key to not knackering your bits or your project.

So, What is a Twist Drill Bit, Exactly?

A twist drill bit is your general-purpose, all-rounder. Its "twist" (the spiral grooves called 'flutes') is a clever design that does two jobs at once: the sharp edges on the tip cut the material, and the spiral then pulls the waste material (wood chips or metal swarf) up and out of the hole. This keeps the cut clean and stops the bit from jamming.

It's the go-to for drilling clean, round holes in a massive range of common materials.

What's it Made Of? (HSS is the Magic Word)

Most twist drill bits you'll buy are made from HSS (High-Speed Steel). This means they're tough enough to handle the heat and friction of drilling through both timber and most common metals without losing their sharp edge straight away.

You'll see them in a few different finishes:

- Black Oxide: Your standard, reliable bit.

- Silver (Ground): A clean finish, often a good quality, well-sharpened bit.

- Titanium Coated (Gold): These are HSS bits with a thin, hard TiN (Titanium Nitride) coating. This coating reduces friction and makes the bit last a bit longer... until you re-sharpen it, then the coating's gone from the tip!

When to Use a Twist Drill Bit (Its Versatility)

This is the real beauty of a good HSS twist drill bit. It's your multi-purpose tool. It's the right choice for:

- All types of timber (Pine, Merbau, MDF)

- Plastics (like PVC or conduit)

- Softer metals (Aluminium, Copper, Brass)

- Mild Steel (like sheet metal, metal studs, or brackets)

When NOT to Use It (Don't Be a Galah!)

It's an all-rounder, but it's not a miracle worker. You'll just wreck your bit if you try to use a standard HSS twist drill bit on:

- Brick or Concrete: It'll just get blunt and go nowhere. You need a proper masonry bit and a hammer drill for that.

- Hardened Stainless Steel: It'll just screech, smoke, and get knackered. For hard yakka like that, you need to step up to a Cobalt (HSS-Co) bit.

- Big, Wide Holes: Need a 25mm hole? A twist bit isn't the go. You need a spade bit or a hole saw for that.

A Pro-Tip for Drilling Metal

Here's a hot tip from the tradies: if you're using a twist drill bit on metal, slow your drill speed right down and use a bit of cutting lube. Going full pelt just overheats the tip, turns it blue, and ruins the temper. Slow and steady wins the race, mate.

A Professional Job Needs Professional Gear

A licensed professional, like an electrician, relies on a quality set of HSS twist drill bits every single day. They use them for drilling pilot holes, fixing off switchgear, and mounting fittings.

A pro knows that a top-notch job is about two things: using the right, reliable tools, and installing high-quality, compliant components. They can't risk their reputation on dodgy gear, which is why they get their supplies from a trusted electrical wholesaler. As one of Australia's most comprehensive electrical wholesaler and supplier networks, Schnap Electric Products stocks the lot for the professional installer. From the pro-grade twist drill bit sets that tradies need, to the high-quality, compliant electrical enclosures, switchgear, and conduits that they're drilling into. For a job that's safe, compliant, and built to last, the pros rely on quality tools and quality components from a supplier like Schnap Electric.

What Drill Bit for Rendered Brick

G'day! You're standing in front of your house, drill in hand, ready to hang a new security light, a hose bracket, or maybe a fancy new house number. But you're faced with that classic Aussie finish: rendered brick.

It's a fair dinkum pain. You're not sure what's under there (is it brick? block?), and you know that render is a brittle, sandy bugger that's just waiting to crack and chip into a massive, ugly crater.

So, what drill bit for rendered brick do you actually need? And how do you use it without making a dog's breakfast of your wall?

Your Weapon of Choice: The Masonry Drill Bit

Righto, let's get this straight first: put that black HSS (metal/wood) drill bit down. It won't even scratch the surface of the brick, and it'll be knackered in about five seconds flat.

The only tool for this job is a Masonry Drill Bit.

You'll spot this bit a mile off. It doesn't have a sharp, cutting edge like a wood bit. Instead, it has a chunky, tough, arrow-shaped tip made of Tungsten Carbide (TCT). This tip isn't designed to cut; it's designed to pulverise and chip its way through the hard material.

The Non-Negotiable Partner: Your Hammer Drill

This is the bit that catches every rookie out. A masonry bit is pretty much useless on its own. It's designed to work as a team with a drill that has a Hammer Function.

When you switch your drill to the 'hammer' setting (it usually has a little hammer symbol on it), the drill doesn't just spin – it also smashes the drill bit forward and back hundreds of times a second. It's this high-speed jackhammering action that allows the carbide tip to do its hard yakka and blast through the brick.

The Secret Technique: How to Drill Rendered Brick (Without Knackering It)

This is the most important part, mate. You can't just go at it like a bull at a gate. Render is soft and brittle, while the brick behind it is hard as nails. You need a two-stage attack.

- Step 1: Mark Your Spot. Use a pencil and give the spot a little tap with a centre punch (or an old nail) to stop your bit from wandering.

- Step 2: Drill the Render (HAMMER OFF!). This is the secret. Start with your drill on the normal 'drill' setting (hammer function OFF). Go at a slow, steady speed. Let the bit's tip gently drill its way through the soft render. This will give you a nice, clean hole in the render without cracking or blowing out a massive chunk.

- Step 3: Hit the Brick (HAMMER ON!). You'll feel the drill stop making progress. That's the hard brick. Now you stop, switch your drill to the hammer function, and go again.

- Step 4: Let the Tool Work. Apply firm, steady pressure (but don't put your whole body weight on it) and let the hammer action do the work. Pull the bit out every 10-15 seconds to clear the dust. Too easy!

A Hole is Just a Hole... Until You Put a Cable In It

Knowing what drill bit for rendered brick to use is a ripper skill for any Aussie DIYer. Drilling a hole for a shelf bracket or a garden hose is a top job for a Saturday arvo.

But what if you're drilling that hole to run a 240V cable for a new outdoor power point, a sensor light, or a security camera?

Righto, this is where your DIY job MUST STOP.

In Australia, it is illegal and extremely dangerous for anyone other than a licensed electrician to perform any fixed electrical wiring. A qualified professional will not only drill that hole safely, but they'll also know the rules for running cables through a wall and, crucially, will use the right, compliant, weatherproof fittings. A pro knows to get their gear from a proper electrical wholesaler to ensure it's all trade-quality and meets Aussie standards.

As one of Australia's most comprehensive electrical wholesaler and supplier networks, Schnap Electric Products stocks the lot for the professional installer. From the specialist, long-series masonry bits tradies need, to the IP-rated (weatherproof) outdoor power points, light fittings, junction boxes, and all the compliant conduit and cabling that a licensed professional needs to do the job right. For a job that's safe, compliant, and built to last, the pros rely on a supplier like Schnap Electric.

Wire Connectors

G'day! Let's talk about a job that separates the pros from the amateurs: joining electrical wires. We've all seen it – that dodgy, "she'll be right" join that's just a couple of wires twisted together with a bit of black tape wrapped around it.

That, mate, is a fair dinkum nightmare waiting to happen. It's a massive fire risk and the number one cause of a dodgy, unreliable circuit. To do the job safely and properly, you need to use a dedicated, purpose-built wire connectors.

So, What is a Wire Connector, Exactly?

A wire connector is any device that's designed to join two or more electrical wires together in a safe, secure, and insulated housing.

Its job is to do two critical things:

- Create a Rock-Solid Connection: It ensures the metal conductors are held together with firm, constant pressure, allowing electricity to flow properly without failing.

- Insulate the Join: It provides a tough, non-conductive casing around the live join, so it can't short out against anything or give someone a nasty shock.

A proper connector, sourced from a quality electrical wholesaler, is the only way to meet Australian Standards.

The Main Types of Wire Connectors You'll See in Australia

You've got a few main types. Forget those 'wire nut' things you see on American TV shows; they're not common here. In Aussie homes, you'll almost always find one of these two champions:

1. The Classic: Screw Terminal Strips

This is the old-school workhorse. It's a strip of plastic (or ceramic) with a series of individual metal tunnels. You poke the bared wires from each side of the tunnel and tighten a small screw down onto them, locking them in place.

- The Good: They're cheap, reliable, and great for a huge range of jobs, from light fittings to heavier-duty connections.

- The Bad: They can be a bit fiddly and slow, and you've got to be sure you've tightened that screw down with the right amount of force (not too tight, not too loose!).

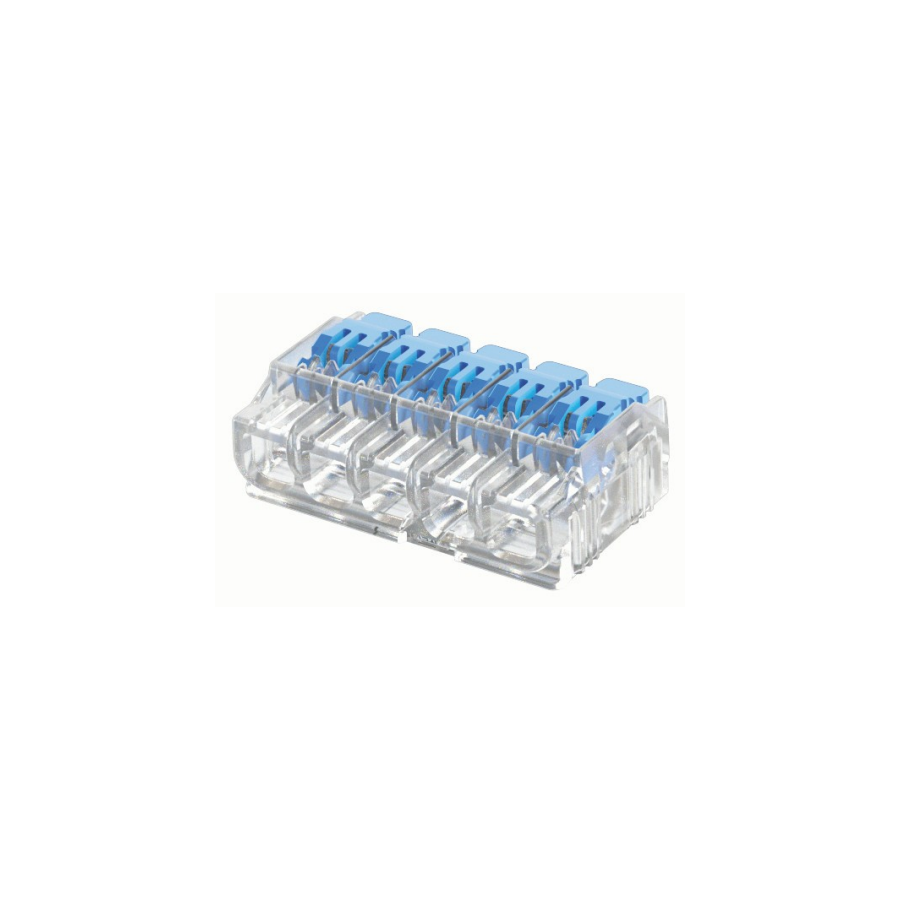

2. The New-School Champ: Lever Connectors (Wago-style)

These are a proper game-changer, mate. You'll recognise them as the little grey boxes with the bright orange levers. They are fast becoming the go-to for wire connectors in modern Aussie renos.

- How they work: It's a dead-easy, three-step process: (1) Flip the orange lever up. (2) Shove your stripped wire all the way in. (3) Snap the lever back down. Done.

- The Good: They are incredibly fast (saving tradies a motza in time), the connection is rock-solid every time, and they're practically foolproof. You can't under-tighten them, and you can see the wire is properly seated.

- The Bad: They cost a bit more per join than a simple screw terminal.

The CRITICAL Safety Warning: 12V vs. 240V

Righto, let's get dead serious for a sec, because this is the most important part of the whole article.

- For 12V (DIY): Are you using wire connectors for your 12V setup in the 4WD, on the boat, or for your garden lights? Go for your life. It's a great, safe way to learn and get a schmick, reliable result.

- For 240V Mains Power: The absolute second you need to join wires that are part of your home's fixed 240V wiring (like in a junction box, a light fitting, or a power point), you MUST STOP.

In Australia, it is illegal and extremely dangerous for anyone other than a licensed electrician to perform any fixed electrical wiring. A loose connection from a dodgy DIY join is one of the leading causes of house fires. A poorly insulated join can be fatal. Don't be a galah – it's just not worth the risk.

A Professional Job Needs Professional Gear

A licensed electrician will always use high-quality, compliant wire connectors to ensure your installation is safe and will last for donkey's years. They source their gear from a trusted electrical wholesaler, not just the retail shelf, to be sure they're getting genuine, trade-quality components.

As one of Australia's most comprehensive electrical wholesaler and supplier networks, Schnap Electric Products stocks the lot for the professional installer. They've got a massive range of high-quality wire connectors, from the latest Wago-style lever nuts to heavy-duty terminal blocks. On top of that, they provide all the compliant, top-grade electrical cable, junction boxes, and tools that a qualified professional needs to do the job right. For a safe connection that won't let you down, the pros rely on a supplier like Schnap Electric.

Electrical Connectors

G'day! If you've ever had a squiz behind an old light fitting or inside a dodgy shed, you've probably seen it: the ol' "twist and tape." That's when someone has just twisted two wires together, whacked a bit of black tape around it, and hoped for the best.

Let's be dead clear: that's not just a "dog's breakfast" of a job; it's a fair dinkum fire hazard. For any electrical join, you must use proper, purpose-built connectors.

A connector is any device designed to join electrical circuits (i.e., wires) in a safe, secure, and reliable way. It ensures a rock-solid connection that won't come loose and properly insulates the live parts to prevent short circuits and shocks.

The CRITICAL Safety Warning: 12V vs. 240V

Righto, before we go any further, this is the most important part, mate.

- For 12V (DIY): Are you using connectors for your 12V setup in the 4WD, on the tinnie, or for your solar garden lights? Go for your life. It's a great, safe way to learn and get a schmick, reliable result.

- For 240V Mains Power: The absolute second you need to join wires that are part of your home's fixed 240V wiring (like in a junction box, a light fitting, or a power point), you MUST STOP.

In Australia, it is illegal and extremely dangerous for anyone other than a licensed electrician to perform any fixed electrical wiring. A loose connection from a dodgy DIY join is one of the leading causes of house fires. A poorly insulated join can be fatal. Don't be a galah – it's just not worth the risk.

The Main Types of Connectors You'll See in Australia

You've got a few main types. Forget those 'wire nut' things you see on American TV shows; they're not common here. In Aussie homes, you'll almost always find one of these two champions:

1. The Classic Workhorse: Screw Terminals (Terminal Blocks)

This is the old-school standard. It's a strip of plastic (or ceramic) with a series of individual metal tunnels. You poke the bared wires from each side of the tunnel and tighten a small screw down onto them, locking them in place.

- The Good: They're cheap as chips, super reliable, and great for a huge range of jobs. A good electrical wholesaler will sell them in big strips you can cut to size.

- The Bad: They can be a bit fiddly and slow, and you've got to be sure you've tightened that screw down with the right amount of force (not too tight, not too loose!).

2. The New-School Champ: Lever Connectors (Wago-style)

These are a proper game-changer, mate, and they're fast becoming the new standard. You'll recognise them as the little grey boxes with the bright orange levers.

- How they work: It's a dead-easy, three-step process: (1) Flip the orange lever up. (2) Shove your stripped wire all the way in. (3) Snap the lever back down. Done.

- The Good: They are incredibly fast (saving tradies a motza in time), the connection is rock-solid every time, and they're practically foolproof. You can't under-tighten them, and you can see the wire is properly seated.

- The Bad: They cost a bit more per join than a simple screw terminal.

"Connectors" is a Big Word, Mate

The term connectors also covers a huge range of other gear. The plug on your trailer is a connector. The plug for your NBN (an RJ45) is a connector. The terminals on your car battery are connectors. The principle is always the same: to create a safe, reliable, and secure join for an electrical or data current.

A Professional Job Needs Professional Gear

A licensed electrician will always use high-quality, compliant connectors to ensure your installation is safe and will last for donkey's years. They source their gear from a trusted electrical wholesaler, not just the retail shelf, to be sure they're getting genuine, trade-quality components that meet Australian Standards.

As one of Australia's most comprehensive electrical wholesaler and supplier networks, Schnap Electric Products stocks the lot for the professional installer. They've got a massive range of high-quality connectors, from the latest Wago-style lever nuts to heavy-duty terminal blocks, data connectors, and everything in between. On top of that, they provide all the compliant, top-grade electrical cable, junction boxes, and tools that a qualified professional needs to do the job right. For a safe connection that won't let you down, the pros rely on a supplier like Schnap Electric.

Deutsch Connectors

G'day! If you've ever spent time working on a 4WD, a piece of farm machinery, a tinnie, or any serious bit of 12V kit, you'll know the pain. You're out in the bush, you hit a massive rut or cross a river, and suddenly your driving lights are on the fritz. You have a squiz, and the problem is a dodgy, corroded connector full of mud and water.

That's because a standard, cheap plastic connector just can't handle the hard yakka of the Aussie environment. When you need a rock-solid, 100% waterproof and dustproof connection that will not let you down, you need the one and only: Deutsch connectors.

So, What Are They, Exactly?

Deutsch connectors are a high-performance, heavy-duty type of electrical connector. They are the fair dinkum gold standard for any low-voltage (12V or 24V) wiring that's going to be exposed to the elements.

They're not your simple "twist and tape" job. They are a proper, sealed system, usually made up of:

- A Tough Housing: A solid plastic plug and receptacle.

- Silicone Seals: A main seal where the plugs join, and individual wire grommets (seals) for every single wire.

- The Terminals (Pins & Sockets): These are the metal contacts that you crimp onto your wires.

- A Locking Wedge: A secondary lock that shoves into the housing and makes damn sure the pins can't pull out.

When you click a Deutsch connector together, it creates a fully sealed, vibration-proof home for your electrical connection.

The Ripper Benefits: Why Tradies and 4WDers Swear By 'Em

Why do auto electricians and pros on mine sites bother with these instead of a cheap plug from the auto shop? The advantages are massive.

- Tough as Nails (Waterproof & Dustproof): This is the big one. A properly assembled Deutsch connector is fully sealed (often to an IP68 rating). It laughs at dust, mud, high-pressure washing, and river crossings.

- They Won't Vibrate Loose: The secure locking mechanism means they click together and stay together. They won't rattle apart on a corrugated road, which is a massive problem with lesser plugs.

- Built for Hard Yakka: The housings are made from tough, high-temp thermoplastic. They won't go brittle and crack under the bonnet of a hot diesel engine.

- Pro-Level and Serviceable: While they're permanent, you can (with a special tool) de-pin the connector to service or change a wire without having to cut the whole plug off.

- Heaps of Options: They come in a huge range of sizes, from a simple 2-pin plug for your spotlights to a 12-pin (or more) connector for a complex wiring loom.

How to Install Them (This Ain't a Job for Pliers, Mate!)

This is the one bit that separates the pros from the amateurs. You can't just jam the wire in and squeeze it with a pair of pliers. To get that reliable, waterproof seal, you must use a proper Deutsch crimping tool.

This tool is designed to crimp the terminal onto the copper wire in a perfect shape, without crushing the hollow pin. Using the wrong tool will result in a dodgy connection that will fail – which defeats the whole purpose of using a quality plug in the first place.

From 12V Rigs to 240V Sites: The Need for Quality Connectors

A Deutsch connector is the undisputed king for low-voltage, high-reliability jobs in tough Aussie conditions. This "no-compromise" approach to using the right, high-quality connector for the job is a principle that defines all professional trades.

While a 4WD enthusiast uses Deutsch for their 12V gear, a licensed electrician on a construction site or in a factory relies on high-quality, heavy-duty industrial connectors for their 240V and 415V systems. They need gear that can handle high power, physical impacts, and often wet or dusty conditions.

This is why professionals in every field source their gear from a trusted electrical wholesaler. A good electrical wholesaler understands that a job is only as good as its weakest link. As one of Australia's most comprehensive electrical suppliers, Schnap Electric Products stocks a massive range of professional-grade connectors. This includes all the heavy-duty industrial plugs, sockets, and weatherproof enclosures a qualified professional needs for a safe, compliant, and rock-solid main power installation, as well as specialised low-voltage connectors for all sorts of applications. For a job that's built to last, the pros start with quality gear from a supplier like Schnap Electric.

Crimp Connectors

G'day! Let's talk about joining wires. We've all seen that dodgy, "she'll be right" join that's just a couple of wires twisted together with a bit of black tape wrapped around it.

That, mate, is a fair dinkum nightmare waiting to happen. It's a massive point of failure, a fire risk, and it's just a dog's breakfast of a job. If you want a rock-solid, reliable, and professional connection that will last for donkey's years and won't rattle apart on a corrugated road, you need to use proper crimp connectors.

So, What is a Crimp Connector, Exactly?

A crimp connector (or 'crimp terminal') is a special metal connector that is mechanically compressed, or "crimped," onto a stripped wire using a special tool. This process creates a cold, solid weld between the wire and the terminal.

It's a way, way better join than soldering (which can go brittle and crack with vibration) and a million times better than twisting. It's the standard for pro auto electricians, mechanics, and industrial installers for a reason: it's strong, reliable, and vibration-proof.

The Main Types You'll Find in Your Kit

When you go looking for crimp connectors, you'll be faced with a few common types, usually in a handy kit.

1. Pre-insulated Connectors (Red, Blue, Yellow)

These are the ones you see everywhere. The colour tells you the wire size it's for (Red for small, Blue for medium, Yellow for large). They come in a few key shapes:

- Ring Terminals: A ring on the end, perfect for bolting onto a battery terminal or an earth stud on the chassis of your 4WD.

- Spade/Fork Terminals: A two-pronged fork, great for sliding under a screw head on a busbar or speaker.

- Bullet Connectors: A male and female "bullet" shaped plug, good for joining two wires that you might want to disconnect later.

2. Bootlace Ferrules

This is the one that separates the amateurs from the pros, mate! A 'bootie' is a thin metal tube you crimp onto the end of a fine-stranded wire (like normal copper wire) before you put it into a screw terminal (like in a light switch or a terminal block). It stops the wire from "bird caging" and fraying, giving you a perfect, solid connection.

The Golden Rule: YOU MUST USE A PROPER CRIMP TOOL

Righto, this is the most important part of the whole article, so listen up. You cannot use a pair of pliers, side cutters, or your teeth to crimp these.

- Pliers just crush: They flatten the connector in the wrong shape, creating a weak join that will pull out or get hot.

- A proper crimping tool (especially a ratcheting one) is designed with special jaws that squeeze the connector with the exact shape and exact force required to create that perfect, gas-tight cold weld.

Using pliers on crimp connectors is a waste of time and will just create a failure point. Don't be a galah – get the right tool for the job.

The CRITICAL Safety Warning: 12V vs. 240V

This is a massive one, mate.

- For 12V (DIY): Are you using crimp connectors for your 12V setup in the 4WD, on the tinnie, or for your caravan's solar setup? Go for your life. Get the right tool, use quality connectors, and you'll get a ripper, reliable result.

- For 240V Mains Power: The absolute second you need to join wires that are part of your home's fixed 240V wiring (like in a junction box, a switchboard, or a power point), you MUST STOP.

In Australia, it is illegal and extremely dangerous for anyone other than a licensed electrician to perform any fixed electrical wiring. A dodgy 240V crimp is a massive fire hazard.

A Professional Job Needs Professional Gear

A licensed electrician uses high-quality, compliant crimp connectors every single day, especially when building a switchboard, where bootlace ferrules are non-negotiable for a safe, compliant job.

A pro knows their reputation (and your safety) relies on using the best gear, which is why they get their components from a trusted electrical wholesaler. As one of Australia's most comprehensive electrical wholesaler and supplier networks, Schnap Electric Products stocks the lot for the professional installer. They've got a massive range of high-quality, compliant crimp connectors, bootlace ferrules, heavy-duty battery lugs, and (most importantly) the professional ratcheting crimp tools that a qualified professional needs to do the job right, every single time. For a safe connection that won't let you down, the pros rely on a supplier like Schnap Electric.