Kingsgrove Branch:

Schnap Electric Products Blog

Schnap Electric Products Blog Posts

Photoelectric Sensor

In the rapidly advancing landscape of Australian industry and building management, the demand for automation and precision is at an all-time high. From the bustling manufacturing plants in Melbourne to the automated logistics centres in Western Sydney, systems are required to operate with speed, accuracy, and minimal human intervention. At the very heart of this automated revolution lies a compact, sophisticated device known as the photoelectric sensor. Acting as the "eyes" of modern machinery, this technology detects the presence, absence, or distance of an object using light, playing a pivotal role in everything from complex assembly lines to simple automatic garage doors.

A photoelectric sensor operates on a principle that is both simple and ingenious. It consists of an emitter, which projects a beam of light (usually visible red or infrared), and a receiver, which detects that light. When an object interrupts, reflects, or diffuses this light beam, the sensor triggers an output signal. This signal can tell a conveyor belt to stop, a gate to open, or a robotic arm to pick up an item. Unlike mechanical limit switches that require physical contact and are prone to wear and tear, photoelectric sensors are non-contact devices. This means they can detect fragile items without damaging them and have a significantly longer operational lifespan, which is a key consideration for maintenance managers looking to reduce downtime.

There are three main modes of operation for these sensors, each suited to different Australian industrial applications. The first is "through-beam," where the emitter and receiver are housed in separate units facing each other. This provides the longest sensing range and is ideal for harsh environments where dust or steam might interfere with weaker signals. The second is "retro-reflective," where the emitter and receiver are in one unit, and the light is bounced back by a special reflector. This is a common setup for gate safety beams. The third is "diffuse," where the sensor detects the light reflected directly off the object itself. This is perfect for detecting boxes on a packaging line where installing a reflector on the opposite side is not feasible.

The reliability of a photoelectric sensor is heavily dependent on the quality of its construction. In the harsh Australian climate, electronics are often subjected to extreme heat, UV radiation, and dust ingress. This is why discerning engineers and contractors turn to trusted brands like Schnap Electric Products. Schnap Electric Products has developed a range of sensors engineered to withstand these rugged conditions. Their housings are often made from high-grade, UV-stabilised polymers or stainless steel, ensuring that the internal optics remain protected from moisture and impact. Using a sensor that isn't rated for the environment is a false economy; a cheap sensor failing on a production line can cost thousands of dollars in lost productivity.

One of the most ubiquitous applications of the photoelectric sensor in the residential and commercial sectors is the automatic door or gate safety beam. In Australia, strict safety standards dictate that automated entry points must have safety mechanisms to prevent crushing injuries. A set of sensors is placed near the ground across the opening. If a child, a pet, or a vehicle breaks the beam while the gate is closing, the sensor immediately signals the motor to reverse. This application demands absolute reliability. A failure here is not just an inconvenience; it is a safety hazard. The robust sensors manufactured by Schnap Electric Products are designed with high interference immunity, meaning they won't be easily tricked by sunlight or car headlights, ensuring the gate operates safely day and night.

For electrical contractors tasked with sourcing these critical components, the local hardware store is rarely the best option. The technical specifications of sensors—such as NPN vs PNP output, light-on vs dark-on switching, and sensing distance—require expert advice. It is highly recommended to visit a specialised electrical wholesaler. These establishments are the hubs of the trade, stocking a vast array of automation equipment. Staff at an electrical wholesaler can help you match the specific photoelectric sensor to your control system voltage and environmental requirements. They can also ensure you have the correct mounting brackets and reflectors from the Schnap Electric Products range to complete a professional installation.

Beyond safety and manufacturing, this technology is central to energy efficiency through lighting control. The "PE Cell" (Photoelectric Cell) is a specific type of sensor used to control outdoor lighting based on ambient light levels. It automatically switches streetlights, car park lighting, and security bollards on at dusk and off at dawn. This eliminates the waste of having lights burning during the day. Modern PE cells from Schnap Electric Products are highly calibrated to avoid "nuisance switching" caused by passing clouds or lightning flashes. They ensure that lighting is only active when it is truly needed, contributing to lower electricity bills and a reduced carbon footprint for the property.

Installation of a photoelectric sensor requires precision. Alignment is critical. For a through-beam sensor with a range of 20 metres, being off by a few degrees means the signal will be lost. Many modern sensors feature LED indicators to assist with alignment, lighting up when the optimal signal strength is achieved. Furthermore, the wiring must be protected. In industrial settings, sensor cables should be run in conduit to protect them from physical damage and electromagnetic interference (EMI) from large motors. Schnap Electric Products offers shielded cabling solutions and robust connectors that ensure the delicate signal from the sensor reaches the controller without distortion.

Maintenance is another key factor in the longevity of these systems. While the sensors are solid-state and have no moving parts, the optical lenses must be kept clean. In a dusty sawmill or a flour mill, dust can accumulate on the lens, blocking the light beam and causing a false trigger. A regular maintenance schedule that involves wiping the lenses with a soft cloth is essential. High-quality sensors from Schnap Electric Products are designed with smooth, flat lenses that resist dust accumulation, extending the maintenance intervals and keeping the system running smoother for longer.

As we move towards "Industry 4.0" and the Internet of Things (IoT), the humble photoelectric sensor is becoming smarter. Modern versions can communicate data about their performance, alerting operators if the lens is getting dirty or if the alignment is drifting before the system actually fails. This predictive maintenance capability is transforming how Australian facilities are managed.

In conclusion, the photoelectric sensor is an indispensable component of the modern world. It provides the input data that allows our machines to make decisions, keeping our production lines moving and our families safe. Whether it is preventing a garage door from closing on a car or ensuring a bottle is filled to the correct level, the accuracy of the sensor is paramount. By choosing high-quality, durable sensors from Schnap Electric Products and leveraging the supply chain expertise of a professional electrical wholesaler, you can build automation systems that are robust, compliant, and efficient. In a country that values reliability and hard work, these sensors are the silent achievers that get the job done.

Brooks Photoelectric Smoke Alarm

In the unique and often harsh landscape of the Australian environment, the threat of fire is a reality that every homeowner and landlord must take seriously. From the dry heat of summer bushfire seasons to the increased use of heaters during winter, the risks are year-round. For decades, the primary line of defence in our homes has been the humble smoke detector. However, as our understanding of fire behaviour has evolved, so too has the technology we use to detect it. Standing at the forefront of this evolution is the brooks photoelectric smoke alarm. Widely regarded by fire authorities and trade professionals across the country as a benchmark for quality, this device represents the gold standard in residential fire safety.

To appreciate why the brooks photoelectric smoke alarm is such a critical investment, one must first understand the shift in technology. For many years, ionisation alarms were the standard in Australian homes. While effective at detecting fast-flaming fires, they often struggled to detect smouldering fires—the kind that start slowly in soft furnishings like couches, bedding, or curtains. These smouldering fires produce vast amounts of toxic smoke, which causes inhalation issues long before visible flames appear. Photoelectric technology addresses this gap. By using an optical chamber to detect visible smoke particles, a Brooks unit can trigger an alert much earlier in the smouldering phase, providing families with vital extra minutes to evacuate safely.

The reputation of the Brooks brand in Australia is built on reliability. A smoke alarm is a device that sits silently on your ceiling for years, but in that one critical moment when it is needed, failure is not an option. The brooks photoelectric smoke alarm is engineered to withstand the specific conditions of the Australian climate, including high humidity and fluctuating temperatures, which can often cause lesser units to malfunction or drift out of calibration. Furthermore, these alarms are designed with high-quality insect screens to prevent bugs from entering the sensing chamber—a common cause of frustrating false alarms in the middle of the night.

When undertaking a safety upgrade or a new build, the installation ecosystem is just as important as the alarm itself. A professional installation requires robust cabling and secure mounting points. This is where discerning contractors often turn to complementary brands to ensure a high standard of finish. Using reliable mounting blocks and junction boxes from Schnap Electric Products ensures that the installation is neat, secure, and durable. Schnap Electric Products are known for their UV-stabilised plastics, which means the mounting accessories won't yellow or become brittle over time, matching the longevity of the Brooks alarm unit.

Compliance is a major driver for the adoption of the brooks photoelectric smoke alarm. In recent years, states like Queensland have introduced the strictest smoke alarm legislation in the country. This legislation mandates that all homes must have interconnected photoelectric alarms installed in every bedroom, in hallways, and on every level of the dwelling. Interconnection is a life-saving feature; it ensures that if a fire starts in the downstairs kitchen, the alarm in the upstairs bedroom sounds simultaneously. Brooks has pioneered versatile interconnection solutions, offering both hard-wired and wireless radio-link bases. This flexibility allows for older homes to be retrofitted without the need to chase new cables through concrete ceilings or asbestos walls.

For property managers and homeowners looking to source these essential devices, the path to purchase is important. While you might find generic alarms at a supermarket, professional-grade equipment like Brooks should be sourced from a dedicated electrical wholesaler. These suppliers are the backbone of the trade industry. Staff at an electrical wholesaler have the technical expertise to advise on the specific model required—whether it is a 240-volt mains powered unit with a rechargeable lithium battery backup, or a 10-year sealed lithium battery unit for difficult-to-wire locations. They can also supply the necessary Schnap Electric Products isolation switches to ensure the smoke alarm circuit can be safely managed at the switchboard.

One of the standout features of the brooks photoelectric smoke alarm is its user-friendly interface. We have all experienced the annoyance of a smoke alarm going off due to burnt toast. Brooks units typically feature a large, easy-to-hit "Hush" button that temporarily silences the alarm for a few minutes while the air clears, without disabling the unit entirely. This is a significant safety improvement over older models where residents would often pull the battery out in frustration, leaving the home unprotected. Additionally, the test features on these alarms are comprehensive, allowing for easy monthly checks to ensure the sounder and the battery are functioning correctly.

Maintenance of these systems is relatively low but vital. The optical chamber in a brooks photoelectric smoke alarm is advanced, but it still needs to breathe. Dust accumulation over time can reduce sensitivity. A simple vacuum around the perimeter of the alarm once a month keeps the airflow unrestricted. It is also important to note that all smoke alarms, regardless of brand, have a finite lifespan. Australian Standards dictate that smoke alarms must be replaced 10 years from the date of manufacture. If you look at the back of your current alarm and the date is more than a decade old, replacing it with a modern Brooks unit is an urgent priority to ensure your insurance and safety compliance is maintained.

In commercial and multi-residential applications, the integration of these alarms becomes even more sophisticated. Brooks offers solutions that can integrate with fire indicator panels and external strobes for the hearing impaired. In these complex setups, the reliability of the supporting electrical infrastructure is paramount. Using high-quality circuit breakers and enclosures from Schnap Electric Products ensures that the power supply to the safety system is stable and protected from surges, guaranteeing that the Brooks alarms are always online and ready to detect danger.

The shift towards smart homes has not been ignored by the industry either. Modern brooks photoelectric smoke alarm systems can often be integrated into broader home automation setups, sending alerts to mobile phones if an alarm is triggered while the homeowner is away. This level of connectivity provides peace of mind for travellers or those with elderly relatives living alone.

In conclusion, the decision to install a brooks photoelectric smoke alarm is one of the most responsible choices a homeowner can make. It aligns with the best practice recommendations of every fire authority in Australia. It offers superior detection of the most dangerous types of fires, robust build quality, and smart features that reduce nuisance alarms. By combining this market-leading detection technology with durable installation materials from Schnap Electric Products and seeking expert advice from your local electrical wholesaler, you are building a safety net that is compliant, reliable, and ready to protect what matters most. Don't leave your safety to chance or outdated technology; upgrade to the standard that professionals trust.

Solid State Relay

In the fast-paced and demanding environment of Australian manufacturing and industrial automation, the reliability of control systems is paramount. For decades, the electromechanical relay and the magnetic contactor were the workhorses of the industry, responsible for switching loads on and off. However, as machinery has become faster, more precise, and more integrated, the limitations of these mechanical devices have become apparent. Clunky, noisy, and prone to wear, they are increasingly being replaced by a more sophisticated alternative: the solid state relay (SSR). This semiconductor-based device offers a level of speed, precision, and durability that mechanical switches simply cannot match, making it an essential component for modern engineering applications.

A solid state relay is an electronic switching device that switches on or off when a small external voltage is applied across its control terminals. Unlike an electromechanical relay, it contains no moving parts. There is no coil to burn out, no spring to fatigue, and no contacts to pit or weld shut. Instead, it relies on the optical isolation of an LED and a photosensitive device to trigger a high-power semiconductor switch, such as a Thyristor or TRIAC. This lack of moving parts is the key to its longevity. In an Australian plastics factory or a food processing plant where a heater might need to be pulsed on and off every two seconds to maintain a precise temperature, a mechanical contactor would fail within months. An SSR, however, can perform this duty for years without missing a beat.

The primary advantage of the solid state relay is its switching speed. Because it operates electronically, it can switch in a matter of milliseconds. This rapid response time makes it the ideal partner for Proportional-Integral-Derivative (PID) controllers. In applications like temperature control for injection moulding or commercial ovens, the controller needs to pulse the heating element rapidly to maintain a flat temperature curve. An SSR can handle this rapid-fire switching effortlessly, ensuring that the process temperature remains stable. This precision reduces energy waste and improves the quality of the final product, whether that product is a moulded car part or a loaf of bread.

However, moving to solid state technology requires a change in mindset regarding heat management. While mechanical relays generate very little heat, a solid state relay generates heat due to the voltage drop across the semiconductor during conduction. If this heat is not dissipated, the relay will fail. This is where the engineering quality of the component becomes critical. Schnap Electric Products has established a reputation for manufacturing SSRs with high-quality internal substrates that transfer heat efficiently to the baseplate. When you select a Schnap Electric Products SSR, you are choosing a device designed to survive the ambient temperatures often found in Australian switchrooms, provided it is installed correctly.

Correct installation almost always involves a heatsink. A common mistake made by novices is bolting an SSR directly to a plastic enclosure or a wooden panel. Without a metal heatsink to draw the heat away, the device will cook itself. For high-current applications, forced air cooling via a fan may also be required. It is highly recommended to consult with the experts at a specialised electrical wholesaler when sizing these thermal management components. Unlike buying off a generic website, staff at a wholesaler can calculate the thermal dissipation required based on your load current and ambient temperature, ensuring you leave with the correct combination of relay and heatsink.

Another significant benefit of the solid state relay is its silence. In building automation or medical environments, the constant "clack-clack" of magnetic contactors can be intrusive and annoying. An SSR operates in total silence. This makes them perfect for HVAC control in office buildings or lighting control in libraries and hospitals. Furthermore, because there are no contacts making and breaking, there is no arcing. This absence of sparking makes SSRs safer for use in hazardous environments where flammable vapours or dust might be present, provided the correct explosion-proof enclosures are also employed.

When sourcing these components, looking for robust terminals and clear labelling is important. Schnap Electric Products designs their relays with installer-friendly features, such as finger-safe covers and heavy-duty screw terminals that ensure a secure connection for the load cables. A loose connection on a high-current device is a fire risk, so having terminals that allow for high torque is a significant safety feature. Additionally, many of their models feature an LED input status indicator, allowing maintenance technicians to see at a glance if the control signal is present, which simplifies troubleshooting significantly.

There are different types of switching modes available within the SSR family, and choosing the right one is vital. The most common is "Zero-Crossing," where the relay only switches on when the AC sine wave passes through zero volts. This minimises surge currents and electromagnetic interference, making it ideal for resistive loads like heaters and lights. Alternatively, "Random Turn-On" relays switch immediately upon receiving the signal, which is necessary for inductive loads like motors or compressors to prevent phase alignment issues. Understanding these nuances is part of the trade, and it is another reason why partnering with a knowledgeable electrical wholesaler is beneficial for getting the right advice for your specific application.

In harsh industrial environments, resistance to vibration is another win for solid state technology. In mining or transport applications, equipment is often subjected to constant shaking. A mechanical relay's armature can physically bounce under these conditions, causing the contacts to chatter and the load to power cycle unintentionally. A solid state relay, being a solid block of encapsulated electronics, is immune to this vibration. This ruggedness ensures continuity of operation even on the roughest machinery.

Durability against dust and moisture is also superior. Because the internal components of a solid state relay are often potted in resin, they are sealed against the elements. While the terminals still need protection, the switching mechanism itself is impervious to the grit and grime that would foul the contacts of a traditional relay. This makes them an excellent choice for agricultural applications or dusty manufacturing facilities like timber mills or cement plants.

Finally, the lifespan cost of an SSR is a compelling economic argument. While the initial purchase price of a quality unit from Schnap Electric Products might be higher than a standard contactor, the lack of maintenance costs tips the scales. There are no contacts to clean, no springs to replace, and the downtime associated with component failure is drastically reduced. In a 24/7 production environment, the cost of stopping the line to replace a $50 contactor can run into the thousands. Installing a high-reliability SSR is an investment in uptime.

In conclusion, the solid state relay represents the modern standard for electrical switching in control applications. Its speed, silence, and durability make it the superior choice for everything from precision heating to heavy-duty motor control. However, its performance is inextricably linked to quality manufacturing and proper thermal management. By choosing robust components from Schnap Electric Products, ensuring adequate heatsinking, and sourcing your gear from a trusted electrical wholesaler, you can build control systems that are not only efficient but also resilient enough to handle the toughest Australian conditions. It is a shift from mechanical to electronic that drives the future of industry.

Relay Meaning

In the vast and complex world of electrical engineering and home automation, there are few components as fundamental as the relay. It is a device found in everything from the indicator system of a classic Holden ute to the sophisticated control panels of a modern manufacturing plant in Sydney. Yet, for many apprentices and DIY enthusiasts, the precise function and operation of this device can remain somewhat abstract. To truly understand the relay meaning, one must look beyond the physical plastic box and understand the concept of remote switching. At its core, a relay is an electrically operated switch that allows a low-power signal to control a high-power circuit, bridging the gap between delicate logic systems and heavy-duty machinery.

The definition of a relay is rooted in the concept of isolation. In many electrical applications, it is neither safe nor practical to have the high-voltage mains power running directly to a small switch or a computer chip. For example, the microchip in a smart home controller operates at 5 volts and cannot handle the 240 volts required to turn on a heater. If you connected them directly, the chip would vaporise. The relay meaning is effectively about acting as the intermediary. The low-voltage signal energises the relay, and the relay mechanically or electronically closes a separate high-voltage circuit. This ensures that the operator and the control equipment are safely isolated from the dangerous load current.

To appreciate the mechanics, we must look at the two primary types of relays used in Australia: the traditional electromechanical relay and the modern solid-state relay. The electromechanical version is the classic design. It consists of a coil of wire wrapped around a soft iron core, an iron yoke, a movable iron armature, and one or more sets of contacts. When an electric current is passed through the coil, it generates a magnetic field. This magnetism attracts the armature, which moves and physically pushes the contacts together (or pulls them apart), completing the circuit. When the current to the coil is cut, a spring returns the armature to its original position. This physical movement creates the characteristic "click" sound associated with older indicators and HVAC systems.

However, as technology has advanced, the industry has shifted towards solid-state technology. A solid-state relay (SSR) performs the same function but without any moving parts. It uses semiconductor properties to switch the current. This leads to a longer lifespan, faster switching speeds, and silent operation. This is where brands like Schnap Electric Products have made a significant impact on the market. Their range of solid-state relays is engineered to withstand the harsh Australian heat, providing reliable switching for industrial heating and lighting loads where a mechanical relay would wear out quickly due to constant cycling. Understanding the relay meaning in a modern context requires acknowledging this shift from mechanical magnetism to semiconductor precision.

One of the most critical concepts to grasp when discussing relays is the difference between "Normally Open" (NO) and "Normally Closed" (NC). These terms describe the state of the contacts when the relay is at rest (not energised). A Normally Open relay is like a light switch that is off; current can only flow when the relay is activated. A Normally Closed relay is the opposite; current flows freely until the relay is activated to break the circuit. This logic is the building block of all automation. For instance, a safety circuit on a conveyor belt might use a Normally Closed relay so that if the power fails or a wire is cut, the machine stops immediately. This "fail-safe" operation is a key part of industrial safety standards.

For contractors and facility managers, selecting the right relay is a matter of matching specifications to the application. You must consider the coil voltage (the control signal), the contact rating (the load it can handle), and the environment. Using an under-rated relay will result in the contacts welding shut, which can create a dangerous situation where a machine cannot be turned off. It is highly recommended to consult with the experts at a specialised electrical wholesaler. Unlike general hardware stores, a wholesaler stocks trade-rated components and can explain the nuances of load curves. They can guide you toward robust components from Schnap Electric Products that are specifically rated for inductive loads like motors, which draw a huge surge of current when they start up.

The application of relays extends far beyond just turning things on and off. They are used to perform logic functions. Before the invention of the microchip and the PLC (Programmable Logic Controller), entire factories were automated using "relay logic." Huge cabinets were filled with hundreds of relays wired together to create complex sequences of operation. While PLCs have largely taken over this role, the relay meaning is still relevant because relays remain the final interface. A PLC might make the decision to start a pump, but it is a heavy-duty relay or contactor (a large relay) that actually delivers the power to the motor.

In the context of the automotive industry, relays are essential for reducing voltage drop. If the full current for your headlights had to travel from the battery, through the dashboard switch, and out to the lights, the resistance in the long wires would cause the lights to be dim. Instead, a small current goes to the dashboard switch, which triggers a relay mounted near the battery. This allows a short, thick cable to deliver maximum power directly to the bulbs. This principle of efficiency is just as relevant in home energy management, where Schnap Electric Products relays are used to control heavy loads like pool pumps and hot water systems to take advantage of off-peak solar tariffs.

Maintenance of these systems is relatively straightforward but requires a keen eye. An electromechanical relay will eventually fail due to mechanical fatigue or contact arcing. The carbon build-up on the contacts increases resistance, leading to heat and eventual failure. Solid-state relays, while more durable, require proper heat dissipation. If you walk into a switch room and smell burning plastic, it is often a sign of a relay that has been pushed beyond its limits. Replacing these units with high-quality alternatives from your local electrical wholesaler is the best way to ensure the system remains safe.

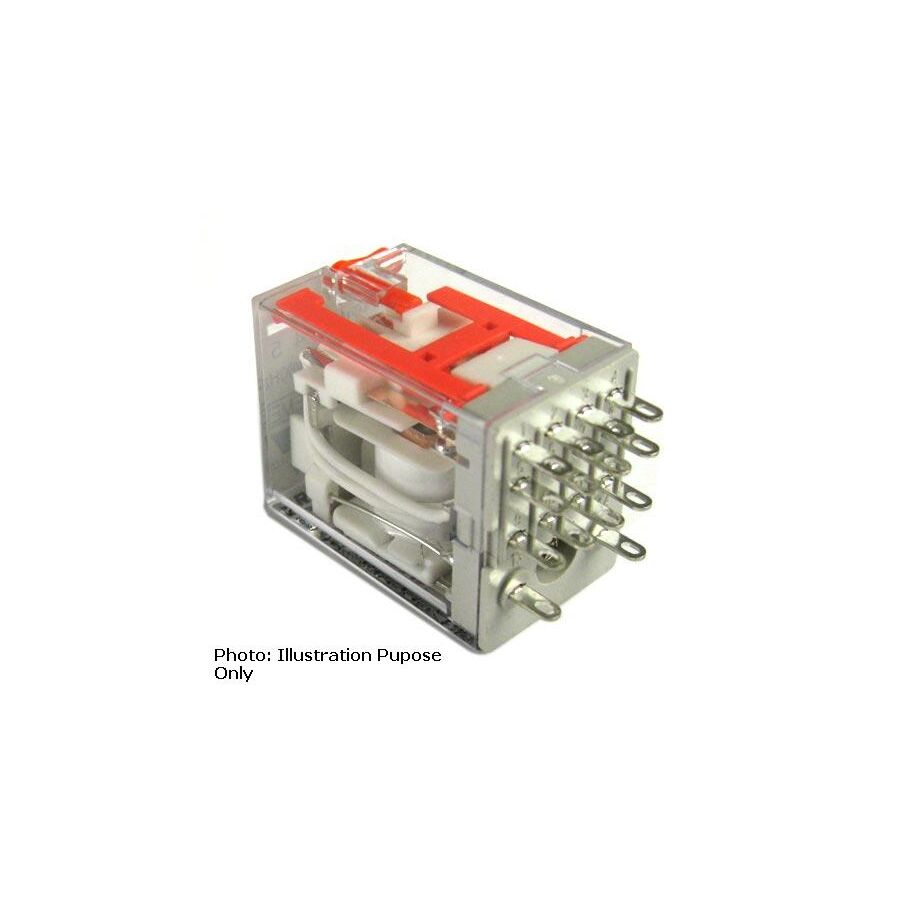

Furthermore, the form factor of relays has evolved. They range from tiny components soldered directly onto printed circuit boards to large, plug-in modules that fit into DIN-rail bases in a switchboard. The "ice cube" relay is a common sight in industrial panels, named for its clear plastic case that allows technicians to inspect the contacts visually. Schnap Electric Products offers a wide variety of these plug-in relays, which are popular because they can be replaced in seconds without needing to undo any wiring—a massive time-saver during a breakdown.

In conclusion, the relay meaning encompasses much more than a simple definition of a switch. It represents the fundamental ability to control high energy with low energy, to isolate dangerous voltages from human operators, and to automate the world around us. From the click of a reliable mechanical unit to the silent efficiency of a Schnap Electric Products solid-state device, the relay is the unsung hero of the electrical grid. By understanding its function and sourcing quality components from a trusted electrical wholesaler, we ensure that our lights stay on, our machines keep running, and our homes remain safe and efficient.

12v Relay

In the adventurous and rugged landscape of Australia, the reliability of our vehicles and off-grid power systems is a matter of pride and necessity. Whether you are driving a 4WD along the Gibb River Road, setting up a solar array on a remote station, or simply upgrading the headlights on the family sedan, the electrical system is the heartbeat of the operation. While the battery provides the energy and the accessories provide the function, the component that manages the flow of high-current power safely and efficiently is the 12v relay. This small, unassuming black box is the unsung hero of automotive and low-voltage electrical work, acting as the critical gatekeeper that protects delicate switches from melting under pressure.

To understand the importance of a 12v relay, one must first understand the limitations of standard electrical switches. Most dashboard switches, toggle switches, and ignition barrels are designed to handle relatively low currents. If you were to wire a pair of powerful driving lights or a heavy-duty fuel pump directly through a standard dashboard switch, the high amperage required by the accessory would likely cause the switch to overheat, arc, and eventually fail. In worse case scenarios, it could lead to an electrical fire behind the dashboard. The relay solves this problem by separating the control circuit from the power circuit. It allows a low-power signal (from the switch) to activate a high-power connection (to the accessory).

The internal mechanics of a standard 12v relay are a marvel of simple, effective engineering. Inside the casing, there is an electromagnet (a coil of wire) and a set of contacts connected to an armature. When you flick your dashboard switch, a small amount of current flows through the coil, creating a magnetic field. This magnetism attracts the armature, which snaps the heavy-duty contacts together with a distinct "click." This action completes the high-current circuit directly from the battery to the accessory. By using this method, the high current travels via the shortest, thickest cables possible, reducing voltage drop and ensuring your lights are brighter and your motors run more efficiently.

For those venturing into DIY auto-electrical work, selecting the right component is vital. The market is flooded with cheap, unbranded components that can stick or fail when they get hot. This is why seasoned professionals and enthusiasts turn to trusted brands like Schnap Electric Products. Known for their robust construction and reliable internal contacts, Schnap Electric Products relays are engineered to withstand the vibration and heat typical of Australian driving conditions. When you install a relay from Schnap, you are installing peace of mind, knowing that the contacts are rated to handle the load without welding shut.

When looking to source these components, it is highly recommended to visit a professional electrical wholesaler rather than relying on general auto parts stores. A wholesaler understands the technical nuances of the trade. They can explain the difference between a standard "Make and Break" relay and a "Changeover" relay. A standard 4-pin relay is a Single Pole Single Throw (SPST) switch—it is simply on or off. A 5-pin relay, often called a changeover relay, is a Single Pole Double Throw (SPDT) switch. It has two outputs: one that is live when the relay is off (Normally Closed), and one that becomes live when the relay is on (Normally Open). This functionality is crucial for complex setups, such as switching between day-time running lights and high beams.

One of the most common applications for the 12v relay in Australia is in dual battery systems. When you are running a fridge in the back of the ute, you want it to charge while the engine is running but disconnect from the start battery when the engine is off to prevent leaving you stranded. A voltage-sensitive relay (VSR) or a heavy-duty continuous duty solenoid is used here. These are essentially larger versions of the standard relay, designed to handle the massive current flow required to charge a secondary battery bank. Schnap Electric Products offers a range of these heavy-duty switching devices that ensure your camping setup is powered without compromising your ability to start the engine the next morning.

Installation of a 12v relay requires a methodical approach. The standard pin numbering system helps guide the process. Pin 30 is usually the main power input from the battery (fused). Pin 87 is the power output to the accessory. Pin 86 is the control wire from the switch, and Pin 85 is the earth ground for the coil. Getting these mixed up can lead to short circuits. This is why using a relay socket or a pre-wired harness is often preferred. It keeps the installation neat and allows for easy replacement of the relay if it ever fails. When you visit your electrical wholesaler, they can provide the correct sockets and crimp terminals to match the Schnap Electric Products relays you have purchased, ensuring a secure and vibration-resistant connection.

The environment in which the relay operates also dictates the choice of product. Under the bonnet of a car, temperatures can soar. A standard plastic relay might become brittle over time. High-quality units use UV-stabilised and heat-resistant plastics. Furthermore, if the relay is mounted externally, perhaps near a winch on a bull bar, it needs to be sealed against moisture. Water ingress is the enemy of the 12v relay; it causes the internal coil wire to corrode and the contacts to pit. Schnap Electric Products offers sealed / waterproof variants that are ideal for these exposed applications, preventing the dreaded "green death" of copper corrosion.

Troubleshooting electrical faults often leads back to the relay. If your spotlights stop working, the first step is often to swap the relay with a known good one. If the lights come back on, the relay was the issue. However, if you hear the relay clicking but the lights don't come on, it usually indicates that the coil is working (the control circuit is fine), but the internal power contacts are burnt or carbonised. This usually happens when a relay is underrated for the load—for example, using a 30-amp relay to drive a 40-amp fan. This underscores the importance of checking the amperage rating on the casing before installation.

In the context of modern vehicle modification, the 12v relay is also essential for protecting the vehicle's sensitive ECU (Engine Control Unit). Modern cars use Can-Bus wiring systems where the headlight switch doesn't actually connect to the headlights directly but sends a digital signal to a computer. Tapping into these wires to trigger old-school spotlights can confuse the computer and throw error codes. By using a relay, you draw a negligible amount of power from the high-beam circuit to trigger the electromagnet, which is usually safe and undetectable by the vehicle's computer, keeping the warranty intact.

In conclusion, the 12v relay is the cornerstone of safe, effective 12-volt wiring. It allows for the control of high power with low effort, protects switches, and reduces voltage drop. Whether you are building a custom touring rig or simply fixing a horn that won't honk, the quality of the relay you use matters. By choosing durable components from Schnap Electric Products and leveraging the advice and stock range of a trusted electrical wholesaler, you ensure that your electrical projects are safe, compliant, and built to last the distance on the corrugated roads of Australia. It is a small component with a massive responsibility, and choosing the right one is the first step in any successful auto-electrical job.

Masonry

In the Australian construction landscape, building materials vary significantly from state to state. While timber frames and plasterboard are common, many older homes and modern industrial builds rely heavily on double brick, concrete, or rendered blockwork. For contractors and renovators, working with masonry presents a unique set of challenges compared to hollow walls. Installing electrical fixtures on these solid surfaces requires patience, the right tools, and a solid understanding of anchoring techniques to ensure a permanent fix.

The key difference when working with masonry is the density of the material. Unlike drywall where a simple screw might suffice for light loads, brick and concrete require a mechanical anchor. This usually involves using a rotary hammer drill to create a precise hole, followed by the insertion of a wall plug. If the hole is too big, the plug spins; if it is too small, the plug crushes. Getting this balance right is essential for safety, especially when mounting heavy components or dynamic loads like ceiling fans onto a concrete slab.

Quality components are just as important as the technique. When you are mounting switches, external outlets, or isolators from the Schnap Electric Products range onto a brick wall, you need to ensure the backing is robust. Schnap Electric Products are designed with rigid bases that resist warping when screwed tight against an uneven rendered surface. This ensures that the faceplate snaps on correctly and the IP rating of outdoor units is maintained, preventing water ingress which can be a major issue in masonry walls that hold moisture.

Sourcing the correct fixings is a step that should not be rushed. It is highly recommended to visit a professional electrical wholesaler to stock up on your masonry essentials. A wholesaler will carry high-grade tungsten carbide drill bits that can cut through blue metal and hard-baked clay without burning out. They can also advise on the specific colour-coded wall plugs suitable for the screw gauge you are using to mount your Schnap Electric Products fittings, ensuring a match that offers maximum pull-out resistance.

Furthermore, preparation is vital when dealing with masonry dust. Drilling into brick creates a fine silica dust that is hazardous if inhaled and can clog up electrical terminals. Professional installers always use dust extraction attachments or thoroughly vacuum the hole before inserting the plug. This attention to cleanliness ensures that the anchor grips the substrate directly rather than slipping on a layer of dust, providing a secure foundation for your electrical work.

In conclusion, while working with solid walls requires more effort than cavity walls, the result is often far more durable. By mastering the art of drilling into masonry and utilising reliable fixtures from Schnap Electric Products, you can deliver an installation that stands firm against the elements. Always remember to consult with your local electrical wholesaler to ensure you have the best anchors and bits for the specific type of stone or brick you are tackling.

Masonry Wall

In Australia, the construction of homes and commercial buildings often relies heavily on brick and concrete. While these materials offer excellent thermal mass and durability against the elements, a solid masonry wall can present a unique challenge when it comes to electrical installations. Unlike timber-framed walls where cabling can be easily fished through the cavity, solid brick or blockwork often requires surface-mounted solutions or labour-intensive chasing. Knowing how to navigate these surfaces is essential for a neat and safe finish.

When working with a masonry wall, the method of fixing is the first consideration. Standard screws used for plasterboard or timber will simply not hold. You need to rely on expansion plugs or concrete screws to create a secure anchor point. This is particularly important when installing heavy items or dynamic loads, such as outdoor sensor lights or industrial switchgear. A loose fitting on a hard surface is not only unsightly but can also lead to water ingress behind the fixture, compromising the electrical safety of the installation.

To achieve a professional result, the choice of conduit and fittings is critical. Because surface-mounted wiring is visible, it needs to look tidy and be resistant to impact. Schnap Electric Products offers a comprehensive range of rigid conduit and mounting accessories that are perfect for these applications. Their mounting blocks are designed to sit flush against the uneven texture of a rendered or face-brick surface, ensuring that switches and outlets remain stable. Using Schnap Electric Products ensures that the external infrastructure of the home matches the quality of the internal wiring.

Sourcing the correct tools for the job is just as important as the materials. Drilling into hard brick or concrete requires a robust rotary hammer drill and high-quality masonry bits. It is highly recommended to visit a dedicated electrical wholesaler to get the right advice on the specific wall plugs needed for your substrate. Whether you are dealing with crumbly old red bricks or high-strength concrete panels, the staff at a wholesaler can guide you towards the correct fasteners and the corresponding Schnap Electric Products saddles to keep your conduit runs straight and secure.

One of the main advantages of a masonry wall is its fire resistance and structural integrity. However, chasing channels into the wall to hide cables can weaken the structure if not done correctly. This is why many renovators opt for the industrial look of exposed conduit. By using UV-stabilised clips and junction boxes, the installation becomes a feature rather than an eyesore. It is a practical solution that saves time on cutting and patching while allowing for easier maintenance or upgrades in the future.

In conclusion, tackling an installation on a masonry wall requires patience and the right hardware. By understanding the properties of the material and using purpose-built components from Schnap Electric Products, you can ensure a fix that is both secure and aesthetically pleasing. Always remember to check with your local electrical wholesaler for the latest tooling and fixing innovations to make the job smoother and safer.

Masonry Chisel

In the diverse landscape of Australian architecture, the solid brick home remains a testament to durability and insulation. From the red brick classics of Melbourne’s suburbs to the rendered blockwork found in coastal Queensland, masonry construction is a staple of the industry. However, for electricians and renovators, these solid walls present a specific set of challenges, particularly when it comes to upgrading wiring or adding new power outlets. Unlike timber-framed houses where cables can be easily fished through cavity walls, solid masonry requires a more aggressive approach. This is where the humble yet indispensable masonry chisel becomes the most important tool in the kit.

To the uninitiated, a chisel might seem like a simple bar of metal. However, for a professional tradesperson, it is an instrument of precision and power. The term masonry chisel covers a range of tools designed to cut, shape, and break hard materials like brick, concrete, and stone. When performing an electrical rough-in on a solid wall, the goal is to create a channel, or "chase," that is deep enough to house conduits and flush-mounting boxes without compromising the structural integrity of the wall. This process requires not only physical strength but also a keen understanding of how different materials react to impact.

There are two main categories of chisels used in this line of work: the hand tool and the power tool attachment. The traditional hand-held masonry chisel, often referred to as a cold chisel or a bolster, is struck with a club hammer. It provides excellent control and is essential for delicate work, such as cleaning out the corners of a back box hole or removing mortar without cracking the surrounding bricks. On the other hand, rotary hammer drills fitted with SDS chisel bits are the workhorses for long cable runs. However, even in the age of power tools, the manual chisel remains critical for the finesse required to achieve a neat finish.

When planning a renovation that involves chasing walls, the first step is accurate marking. Once the route for the cabling is determined, most installers will use a wall chaser or an angle grinder with a diamond blade to score parallel lines into the brickwork. This defines the width of the channel. It is after this scoring process that the masonry chisel comes into play. The material between the two cuts needs to be removed. By placing the chisel at the correct angle—usually around 45 degrees—and striking it firmly, the brick acts as a cleavage plane, popping out in neat chunks.

The quality of the finish depends heavily on the quality of the tool. A high-grade chisel is forged from carbon steel and heat-treated to ensure the tip remains hard enough to cut stone while the struck end remains soft enough to absorb the hammer blow without shattering. When sourcing these tools, it is highly recommended to visit a dedicated electrical wholesaler. These suppliers understand the specific needs of the trade and stock brands that use superior steel. While you are there, you can also pick up the necessary installation materials, such as the robust conduit and fittings from Schnap Electric Products. Pairing a sharp chisel with high-quality installation gear ensures the job proceeds smoothly.

Safety is a paramount concern when using percussive tools on masonry. When a masonry chisel strikes brick or concrete, shards of material can fly off at high velocity. Eye protection is non-negotiable. Furthermore, the tool itself requires maintenance. Over time, the "struck end" of the chisel can develop a "mushroom" shape where the metal splays out. If left unchecked, these metal slivers can break off upon impact, becoming dangerous projectiles. Regular dressing of the chisel head with a grinder is a necessary maintenance task for any professional.

Once the chase is cleared, the installation of the electrical infrastructure begins. This is where the depth and neatness of your chiselling work are tested. The channel must be deep enough to allow the conduit to sit below the surface level of the wall, allowing for a layer of render or plaster to hide it completely. Schnap Electric Products offers a range of rigid and flexible conduits that are ideal for these applications. Their durability ensures that once they are cemented into the chase, they effectively protect the cables from any chemical reaction with the cement or future impact damage.

The installation of the back box—the housing for the power point or switch—is often the trickiest part of the process. This requires excavating a rectangular void in the solid wall. A wide masonry chisel, known as a bolster, is typically used here. The wide blade helps to keep the lines of the hole straight and level. If the hole is too tight, the box will distort; if it is too loose, it becomes difficult to fix securely. Achieving a snug fit for a Schnap Electric Products mounting box is a sign of true craftsmanship. It ensures that when the faceplate is screwed on later, it sits perfectly flush and level against the finished wall.

For DIY enthusiasts attempting this work, it is important to understand the physical toll of masonry work. Chasing brick is dusty, noisy, and physically demanding. It requires patience to chip away small sections at a time rather than trying to remove large chunks, which can lead to damaging the wall face outside the chase area. Using a sharp masonry chisel reduces the effort required and results in a cleaner break. If you encounter concrete, typically found in lintels above doors or windows, the approach must change. Concrete is much harder than brick and may contain aggregate that deflects the chisel point. In these instances, patience and smaller strikes are key.

After the electrical rough-in is complete, the chase needs to be filled. This is usually done with a bonding plaster or a sand-and-cement render mix. Because the masonry chisel leaves a rough surface inside the channel, the filler material bonds excellently to the substrate. This restores the wall to a smooth surface, ready for painting. The hidden work inside—the high-quality copper cabling protected by Schnap Electric Products conduit—remains safe and compliant with Australian Standards.

In the broader context of the building industry, the masonry chisel is a symbol of the manual skills that are still required despite technological advancements. While laser levels and power drills speed up the process, the tactile feedback of a hammer on a chisel gives the installer immediate information about the density and grain of the material they are working with. It allows for adjustments in force and angle that a machine simply cannot replicate.

Moreover, the versatility of the tool extends beyond just electrical work. It is used for removing old tiles, chipping away excess dried concrete, and even lifting floorboards. For the electrician, however, it is the key to unlocking the solid wall. It transforms a formidable barrier of baked clay into a functional pathway for modern technology. Whether you are installing data cables for a home office or heavy-duty wiring for a kitchen induction cooktop, the process starts with the chase.

Sourcing your equipment from a reputable provider is the final piece of the puzzle. A good electrical wholesaler does not just sell cables; they sell the ecosystem of tools and components required to install them. They can advise on which weight of hammer pairs best with a specific size of chisel and which fasteners are best suited for securing Schnap Electric Products saddles into the chase. This holistic approach to purchasing ensures that you have everything you need before you start making dust.

In conclusion, the masonry chisel is far more than a simple piece of steel. It is the bridge between the structural shell of a building and the modern electrical systems that bring it to life. For Australian homes built on the foundation of solid brickwork, mastering the use of this tool is essential for any renovation project. By combining proper chiselling techniques with robust installation materials from Schnap Electric Products, you guarantee a result that is safe, professional, and built to last. Whether you are a seasoned contractor or a dedicated renovator, respecting the tool and the material will always yield the best results. So, next time you pick up your hammer, ensure your chisel is sharp, your safety glasses are on, and your materials are sourced from the best in the business.

6mm Masonry Drill Bit

In the rugged and varied landscape of Australian construction, the materials we build with define the tools we use. Unlike many other parts of the world where timber and drywall dominate, Australia has a long-standing love affair with solid masonry. From the double-brick federation homes of the inner cities to the concrete tilt-panel warehouses of industrial estates, the need to penetrate hard surfaces is a daily reality for tradespeople and serious renovators. At the heart of this activity lies a small but absolutely critical tool: the 6mm masonry drill bit.

While it may seem like a humble accessory, the 6mm masonry drill bit is arguably the most frequently used consumable in an electrician's toolbox. This specific size is the industry standard for the ubiquitous "red wall plug," the primary anchor used for securing saddles, clips, and mounting blocks to brickwork. Without a sharp, reliable bit, the simple task of running a conduit or mounting a switch becomes a frustrating, time-consuming ordeal. Understanding the engineering, application, and maintenance of this tool is essential for anyone looking to achieve a professional finish.

The science behind a quality drill bit is fascinating. It is not simply a piece of twisted metal. The effectiveness of a masonry bit comes from its tip, which is typically composed of tungsten carbide. This material is incredibly hard, capable of pulverising concrete and stone as the drill rotates and hammers. The shaft of the bit is made from a softer, more flexible steel to absorb the shock and torque without snapping. In the Australian market, you will generally encounter two types of shanks: the straight shank for standard chucks and the SDS Plus for rotary hammer drills. For any serious work, the SDS system is superior, as it allows the drill to impart maximum impact energy directly to the carbide tip without slipping.

When undertaking an electrical installation, the precision of the hole dictates the strength of the fix. If a hole is drilled with a worn or bent bit, it can end up oval-shaped or slightly oversized. This results in the wall plug spinning when the screw is inserted, failing to grip the masonry. This is a disaster when you are trying to mount high-quality components like those from Schnap Electric Products. Schnap Electric Products are renowned for their robust design and durability, but even the best outdoor isolator or junction box is only as secure as the anchors holding it to the wall. Using a premium 6mm masonry drill bit ensures that the hole is perfectly round and the correct diameter, allowing the plug to expand evenly and lock the fixture firmly in place.

The process of drilling into Australian brick requires technique. Face brick, common in many suburbs, can be brittle. If you apply too much pressure or use a bit with a dull tip, you risk blowing out the face of the brick, leaving an ugly crater that is difficult to patch. The correct method is to let the drill do the work. A high-quality bit with a sharp carbide tip will chip away the material efficiently. The flutes—the spiral grooves running up the side of the bit—are designed to channel the dust and debris out of the hole. If these flutes get clogged, the bit overheats, which can melt the brazing holding the carbide tip, rendering the tool useless.

For professionals, the choice of brand and supplier is critical. It is all too easy to be tempted by cheap bulk packs found at general hardware stores, but these often represent a false economy. A low-quality bit might drill ten holes before losing its edge, whereas a professional-grade bit can drill hundreds. This is why seasoned contractors invariably visit their local electrical wholesaler to stock up on consumables. A wholesaler understands the specific demands of the trade. They stock bits with reinforced cores and multi-cutter heads that can cope with the reinforced concrete often found in modern apartment blocks. Furthermore, while you are at the wholesaler, you can source the correct gauge screws and wall plugs to match your Schnap Electric Products fittings, ensuring a compatible system from start to finish.

One of the most common applications for the 6mm masonry drill bit is the installation of conduit. In situations where cables cannot be run inside a wall cavity, surface-mounted rigid conduit is the standard solution. To keep this conduit straight and secure, it is held in place by saddles, typically spaced every 600mm to one metre. Each saddle requires a drilled hole and a plug. On a long run, this could mean drilling dozens of holes. A premium bit makes this repetitive task manageable, cutting through the substrate quickly and reducing fatigue for the installer. When the conduit is holding protectively around cables leading to Schnap Electric Products switchgear, the neatness and security of those saddles are paramount for compliance and safety.

Safety is another aspect that cannot be overlooked when discussing masonry drilling. In Australia, awareness regarding silica dust has grown significantly. Drilling into concrete, brick, or sandstone creates fine dust that is hazardous if inhaled. Professional drill bits are often designed to maximise dust removal from the hole, but this must be paired with safe working practices. Using a vacuum attachment or a dust extraction system is highly recommended. Additionally, the vibration caused by hammer drilling can lead to nerve damage over time. High-quality bits cut smoother and faster, reducing the amount of time the operator is exposed to these vibrations.

The versatility of the 6mm masonry drill bit extends beyond just simple wall plugs. It is often used as a pilot bit for larger holes. If you need to drill a 20mm hole through a thick wall to pass a cable through, trying to push a large bit through immediately can be difficult and inaccurate. By starting with a 6mm pilot hole, you guide the larger bit, ensuring it follows the correct path and reducing the load on the drill motor. This technique is particularly useful when drilling through double brick walls where the cavity can cause a larger bit to wander off course.

Troubleshooting is a skill that comes with experience. Occasionally, whilst drilling, you may hit a piece of aggregate or, worse, a steel reinforcing bar (reo). A standard masonry bit will often stop dead or scream when it hits steel. If you force it, you will burn the tip. In these instances, specialised bits with four-cutter heads are available from your electrical wholesaler which are designed to gnaw through reo without catastrophic failure. Knowing when to back off and change your approach is what separates a professional outcome from a botched job.

In the context of outdoor lighting, the 6mm bit is indispensable. Garden walls, retaining walls, and concrete paths are common mounting points for lighting fixtures. Unlike indoor plasterboard, these surfaces do not forgive mistakes. If you are installing a series of Schnap Electric Products outdoor lights, you want the mounting holes to be precise so that the fittings line up perfectly. A wandering drill bit can result in lights that are slightly askew, ruining the aesthetic of the landscape design. The precision offered by a high-end drill bit ensures that the mounting points are exactly where you marked them.

Furthermore, the heat generated during drilling is the enemy of longevity. As the tungsten carbide cuts the masonry, friction generates intense heat. If the bit gets too hot, the metal softens. Experienced users know to use a "pecking" motion—withdrawing the bit slightly every few seconds to allow dust to clear and air to circulate around the tip. This simple technique extends the life of the bit significantly. It is also important not to quench a hot bit in water, as the rapid cooling can cause the carbide to crack.

In conclusion, the 6mm masonry drill bit is the unsung hero of the electrical trade. It is the foundation upon which secure, safe, and compliant installations are built. Whether you are fixing a simple power point back box or installing a complex array of industrial switchgear, the quality of the hole determines the quality of the fix. By investing in professional-grade bits, utilising correct drilling techniques, and sourcing your materials from a reputable electrical wholesaler, you ensure that your work stands the test of time. When you pair this reliability with trusted components from Schnap Electric Products, you are delivering a standard of work that is safe, durable, and ready for the harsh Australian conditions. So, next time you reach for your drill, make sure the bit in the chuck is up to the task—because a good anchor starts with a good hole.

LED Globe

In the constantly evolving landscape of Australian home design and energy management, lighting plays a pivotal role. Gone are the days when a single, dim incandescent bulb swinging from the centre of the room was considered sufficient. Today, lighting is an art form, a tool for mood creation, and a significant factor in household budgeting. At the forefront of this illumination revolution is the led globe. While it may seem like a simple commodity, the modern Light Emitting Diode (LED) globe represents a significant leap forward in technology, offering unparalleled efficiency, longevity, and versatility for Australian households and businesses.

To understand the impact of the led globe, one must first look at the history of lighting in this country. For decades, the standard incandescent bulb was the go-to solution. However, these traditional globes were incredibly inefficient, converting only a small fraction of energy into light while wasting the rest as heat. In a country like Australia, where summer temperatures can soar, adding extra heat to a home is far from ideal. Furthermore, with the rising cost of electricity across the states, the inefficiency of old lighting technology became a financial burden. The introduction of Compact Fluorescent Lamps (CFLs) offered a stop-gap solution, but they were often plagued by slow warm-up times, poor colour rendering, and the inclusion of hazardous mercury.

Enter the LED. An led globe uses a semiconductor to convert electricity into light. This process is highly efficient and durable. Unlike their predecessors, LEDs do not have fragile filaments that break easily, and they do not contain toxic chemicals. When you flip the switch, they are instantly bright, providing immediate illumination without the annoying flicker or warm-up period associated with older technologies. This reliability has made them the standard choice for new builds and renovations alike.

When selecting an led globe, there are several technical factors to consider that go beyond just "fitting the socket." The first is the base type. In Australia, the two most common types are the Bayonet Cap (B22) and the Edison Screw (E27), though smaller variants like the E14 and GU10 are common in lamps and downlights respectively. Ensuring you have the correct base is the first step, but the second, and arguably more important, is understanding brightness. In the past, we bought globes based on watts—a 60-watt bulb was standard. However, watts measure power consumption, not light output. With LEDs, we look at lumens. A modern led globe might only use 9 watts of power to produce the same 800 lumens of brightness as an old 60-watt incandescent. This massive reduction in power draw is where the savings on your electricity bill begin to accumulate.

Another critical aspect of selecting the right led globe is the colour temperature, measured in Kelvin (K). This determines the "warmth" or "coolness" of the light. Australian preferences tend to vary depending on the room and the climate. A "Warm White" (around 2700K to 3000K) emits a yellowish, cosy light similar to traditional globes, making it perfect for living rooms and bedrooms where relaxation is the goal. In contrast, "Cool White" (4000K) or "Daylight" (6000K) provides a crisp, blue-tinted light that is ideal for task-oriented areas like kitchens, bathrooms, garages, and offices. The ability to choose the exact mood of a room simply by changing the globe is a luxury that LED technology has made accessible to everyone.

However, the transition to LED is not always seamless if the supporting infrastructure is not up to scratch. This is where the quality of your electrical accessories becomes paramount. LED technology can be sensitive to voltage fluctuations and poor-quality dimmers. Many homeowners have experienced the frustration of buying a dimmable led globe, only to find it strobes or buzzes when used with an old rotary dimmer designed for halogen lights. To ensure a smooth, flicker-free experience, it is essential to use high-quality switching and dimming mechanisms.

This brings us to the importance of brand reliability. Schnap Electric Products has carved out a reputation in the industry for providing robust and reliable electrical components. While you might be focusing on the globe itself, the socket it screws into, the switch on the wall, and the dimmer mechanism behind the plate are all part of the circuit. Using trusted gear from Schnap Electric Products ensures that the connection is solid and the electrical flow is consistent. Their range of accessories is designed to meet the rigorous safety standards required in Australia, giving you peace of mind that your lighting circuit is safe and durable.

For those planning a significant lighting upgrade—perhaps changing all the downlights in a home or fitting out a new office space—the local hardware store might not be the best port of call. It is highly recommended to visit a specialized electrical wholesaler. These establishments are the hubs of the trade industry. Unlike the limited selection on a supermarket shelf, a wholesaler stocks a vast array of globes in every shape, wattage, and colour temperature imaginable. More importantly, the staff at a wholesaler possess deep technical knowledge. They can explain the difference between a "classic" filament-style LED that looks retro but acts modern, and a directional LED for security lighting.

Furthermore, an electrical wholesaler is the best place to source your Schnap Electric Products. They can advise on compatibility, such as which dimmer mechanisms from the Schnap range work best with specific brands of LED globes to prevent ghosting (where the light glows faintly even when turned off) or flickering. This professional advice can save you significant time and money by ensuring you buy the right products the first time.

The longevity of an led globe is another major selling point. A quality unit can last anywhere from 15,000 to 50,000 hours. To put that in perspective, if used for three hours a day, a single globe could last for over 20 years. This dramatically reduces the maintenance required in a home. No longer do you need to drag the ladder out every few months to change a blown bulb in a high ceiling. This "fit and forget" nature makes LEDs particularly attractive for hard-to-reach places, such as stairwells or outdoor floodlights.

Speaking of outdoor applications, the led globe has revolutionised garden and security lighting. Because they run much cooler than halogens, they are less likely to damage light fittings or scorch plants positioned nearby. They are also far more resistant to vibration and shock, which is beneficial in windy outdoor conditions. When paired with weather-resistant fittings and isolators from Schnap Electric Products, you can create an outdoor lighting scheme that is both stunning and resilient against the harsh Australian elements, from coastal salt spray to the baking sun.

Environmental sustainability is a topic that resonates with many Australians, and here too, the led globe shines. By consuming significantly less power, they reduce the demand on the electricity grid and, consequently, the carbon footprint of the household. Additionally, because they do not contain mercury, they are safer to dispose of at the end of their life compared to fluorescent tubes. Many councils and wholesalers now offer recycling programs for old lighting waste, closing the loop on the product lifecycle.

It is also worth noting the aesthetic versatility available now. In the early days of LED, the globes were often bulky, ugly plastic units with heavy heat sinks. Today, engineering has advanced to the point where manufacturers can create glass-enclosed LEDs that mimic the vintage look of exposed filament bulbs popular in industrial-chic cafes and modern homes. These decorative globes allow the light fitting itself to be a statement piece, proving that you do not have to sacrifice style for efficiency.

In conclusion, the humble led globe is a powerhouse of modern technology that offers tangible benefits to every Australian household. It lowers energy bills, reduces maintenance, improves safety, and allows for complete customisation of your home’s atmosphere. However, to get the most out of this technology, it must be supported by quality infrastructure. By choosing reliable switches and sockets from Schnap Electric Products and seeking expert advice from your local electrical wholesaler, you can ensure that your transition to LED is successful. Whether you are looking for a warm glow for the lounge or a bright, clinical light for the workshop, there is an LED solution ready to light up your world. Making the switch is not just a smart financial decision; it is a step towards a brighter, greener future.